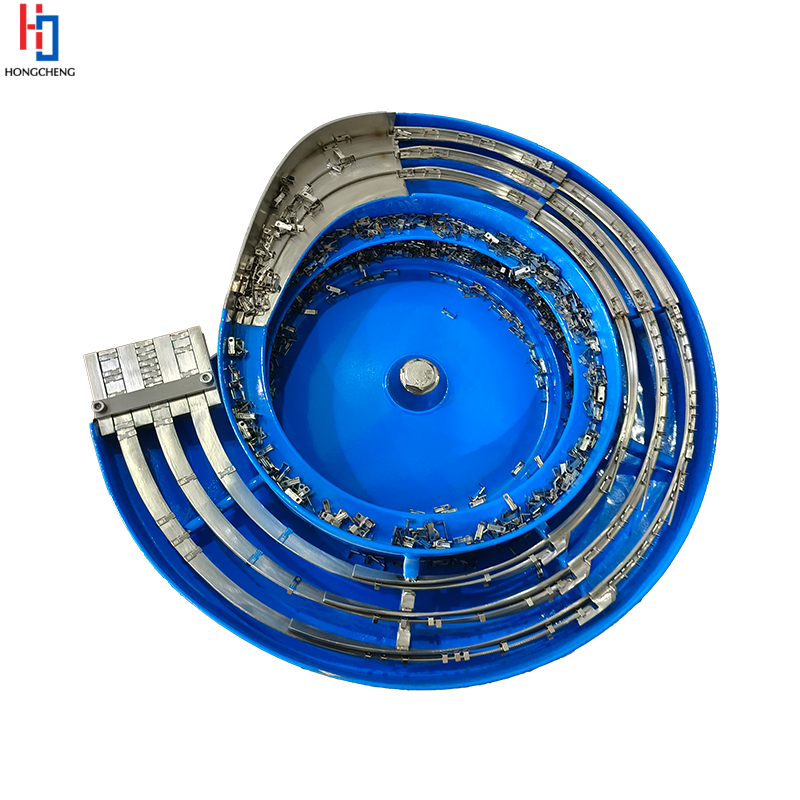

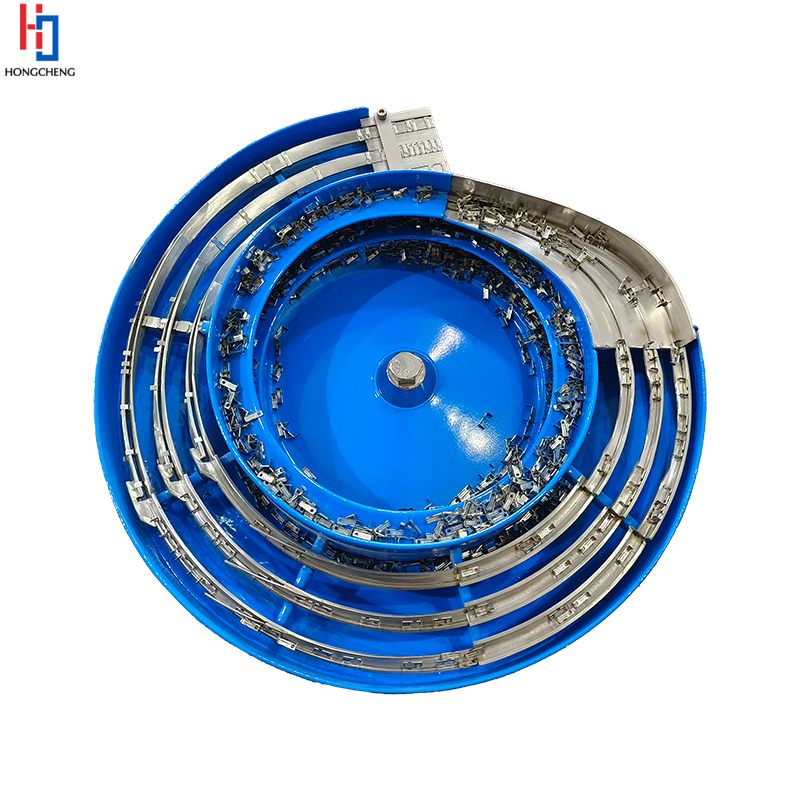

Description of vibratory feed bowl for high density micro connectors:

Vibration bowl feeder for precision part is a feeding device used in the aerospace industry. In the aerospace industry, precision vibration bowl small parts feeder can be used to convey metal particles, powdered composite materials, etc. Required for manufacturing parts, so that subsequent processing links can continuously and stably obtain materials, improve production efficiency and product quality. In the casting and forging processes of aerospace parts, precision vibration bowl small parts feeder can continuously and evenly feed furnaces, forging presses and other equipment to avoid problems such as material jamming.

Advantages of vibration bowl feeder for precision part:

1. The structure of vibration bowl feeder for precision part is simple and compact, which can adapt to the working environment of aerospace and is convenient for installation and debugging.

2. The adjustment performance of precision vibration bowl small parts feeder is good, which can meet the production requirements of aerospace.

3. Vibratory feed bowl for high density micro connectors consumes less power and can reduce the production cost of the aerospace industry.

Why does the vibration electromagnet of vibration bowl feeder for precision part fail?

The core component of precision vibration bowl small parts feeder is the vibration electromagnet, which drives the bowl to move by generating electromagnetic vibration. If there is a problem with the electromagnet, vibratory feed bowl for high density micro connectors May cause insufficient vibration or uneven amplitude. This problem May cause the electromagnet to age or be damaged, resulting in a weakened magnetic field strength or poor line contact or unstable voltage, which affects the work of the electromagnet. Another reason is that the electromagnet coil accumulates too much dust, which affects heat dissipation and reduces work efficiency. If we encounter this problem during use, we must check the electromagnet of the vibration bowl feeder for precision part to see if it is aging or has signs of damage, and replace it if necessary. In addition, we must ensure stable power supply and use a voltage stabilizer to avoid the influence of voltage fluctuations. And regularly clean the dust and debris on the surface of the electromagnet to keep the heat dissipation normal.

How to debug the equipment of precision vibration bowl small parts feeder?

Before we officially use the vibratory feed bowl for high density micro connectors, we must first debug and test to ensure that the equipment is in good operating condition. According to the characteristics of aerospace industry materials, adjust the frequency and amplitude of vibration so that it can be transported smoothly. Check the track of the vibratory feed bowl for high density micro connectors to make the track angle and guide device correct to avoid material jamming or deviation from the direction. Before formal use, conduct a short-term test to observe the feeding speed and stability of the vibration bowl feeder for precision part. If there is any abnormality, adjust it in time.

Company profile:

Hongcheng automation's vibration plates and automation equipment are widely used in many industries, including light industrial machinery, button manufacturing, zipper assembly, cork processing, connector production, battery manufacturing, semiconductor testing, etc. Our equipment can improve production efficiency, reduce manual operations, ensure product accuracy and consistency, and is suitable for the automated production needs of electronic precision products.