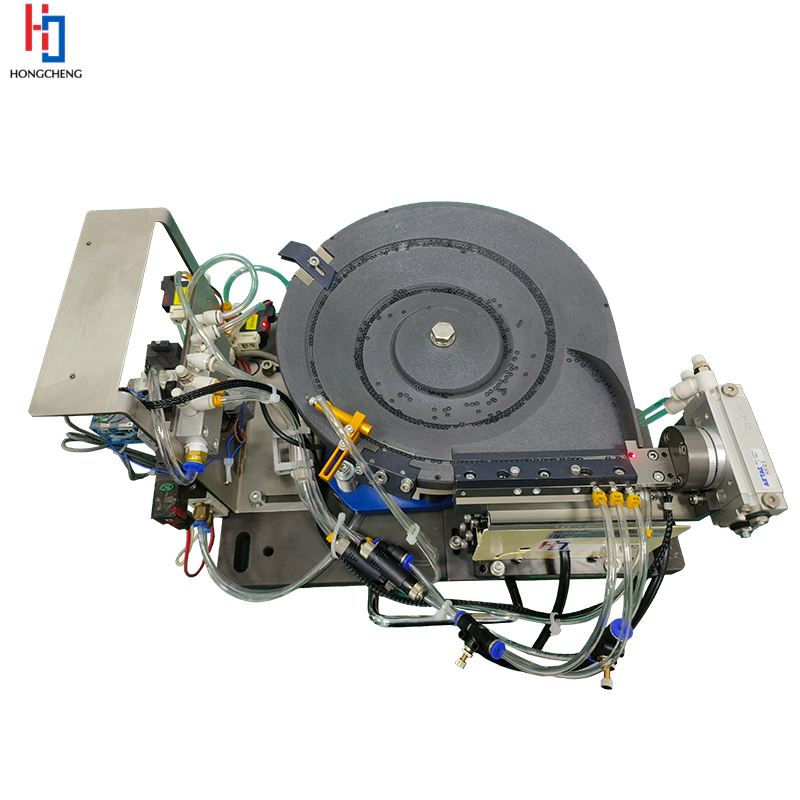

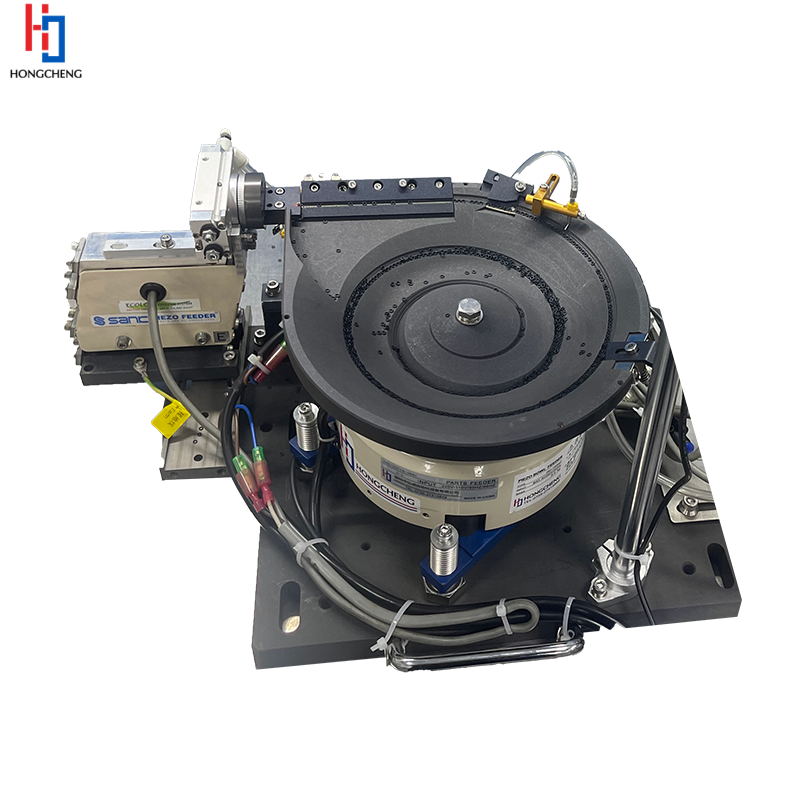

Introduction of o-ring parts feeding system:

Multi functional hardware parts vibrating feeder is an automated device that automatically arranges scattered and disordered parts in an orderly manner and transfers them to the next process. Aluminum vibratory feeder bowls for hardware usually consists of a tray, a base, a vibrating drive, a spiral track, an exit track, a control system, a screening device, a shock absorber and a bracket. Vibrating bowl feeder for o ring uses high-frequency vibration to make the parts move in a specified direction and speed, thereby realizing the function of conveying and sorting parts.

Advantages of o-ring parts feeding system:

1. O-ring parts feeding system has a wide range of applicability and can be used for parts of various shapes and sizes, especially for small hard parts such as metal and plastic.

2. Aluminum vibratory feeder bowls for hardware can accurately transfer and place parts as required and transfer them to the next process.

3. Multi functional hardware parts vibrating feeder can be seamlessly integrated with other automation equipment to form a complete automated production line.

4.Vibrating bowl feeder for o ring is usually equipped with a protective cover and safety switch to ensure the safety of the operator.

Which hardware parts are suitable for o-ring parts feeding system?

1.Screws: Aluminum vibratory feeder bowls for hardware can be used for the automated assembly, packaging and testing of self-tapping screws, machine screws, wood screws, etc.

2.Nuts: Vibrating bowl feeder for o ring are used for the assembly of hexagonal nuts, lock nuts, flange nuts, etc.

3.Gaskets: Multi functional hardware parts vibrating feeder can be used for the delivery and sorting of flat washers, spring washers, toothed washers, etc.

4.Springs: Multi functional hardware parts vibrating feeder can be used for the automated assembly and testing of compression springs, tension springs, torsion springs, etc.

5.Washers:Vibrating bowl feeder for o ring is used for the automated assembly and gap adjustment of round washers, square washers, nylon washers, etc.

6.Small metal parts: Vibrating bowl feeder for o ring is used for the automated assembly, packaging and testing of metal sheets, metal rings, metal clips, etc.

Parameters of o-ring parts feeding system:

| Name: | O-Ring Parts Feeding System | Specification: | XYD——300 Vibration |

| Chassis Size: | 300 | Weight: | 10KG |

| Voltage: | AV220V (50-220 Adjustable) | Controller Type: | Frequency Controller |

| Speed: | 60/m | Disk Diameter: | 300mm |

Maintenance and maintenance of o-ring parts feeding system:

In order to ensure the normal operation of o-ring parts feeding system, we need to maintain the equipment regularly. After long-term use, there will be metal chips and dust residues in the vibrating plate of aluminum vibratory feeder bowls for hardware. We need to clean them in time to avoid blockage during transportation. We also need to check the vibrating parts of multi functional hardware parts vibrating feeder frequently. If the relevant parts (springs, vibrating plates, etc.) are damaged and deformed, they need to be replaced in time. Usually, you should also pay more attention to the feeding of vibrating bowl feeder for o ring, and observe whether the feeding speed and feeding direction are normal. If you find abnormalities, you can adjust the vibration frequency and track guide.

FAQ:

1. How to adjust the feeding speed of vibrating bowl feeder for o ring?

A: It can be adjusted by adjusting the vibration frequency and amplitude of the vibrating plate. The controller configured by the equipment can adjust the parameters manually or automatically. If you want a faster feeding speed, increase the speed appropriately. If you want a more precise arrangement, reduce the amplitude.

2. What are the common faults of vibrating bowl feeder for o ring?

A: Generally speaking, if the hardware vibratory feeder bowl is regularly inspected and maintained, the probability of failure is very small. If it is not maintained for a long time or used abnormally, the following problems May occur: Unstable feeding speed, parts stuck or inaccurate arrangement.

3. How to solve common faults of hardware vibratory feeder bowl?

A: The problems of unstable feeding speed, parts stuck or inaccurate arrangement are usually caused by track blockage, spring sheet damage or improper electromagnet gap. The solution is to clean the track regularly, check and replace damaged spring sheets, and adjust the gap between the electromagnet and the vibrating plate.

About us:

Shenzhen Hongcheng Automation Equipment Co., Ltd. is a high-tech enterprise focusing on the research and development, production and sales of non-standard automation equipment, and is committed to providing customers with efficient, reliable and customized automation solutions. The company's main products are various types of feed trays, and it has accumulated rich experience in the research and development, sales and service of related fields. Adhere to customer needs as the core, continue to innovate, and improve product quality and service standards.