Product introduction:

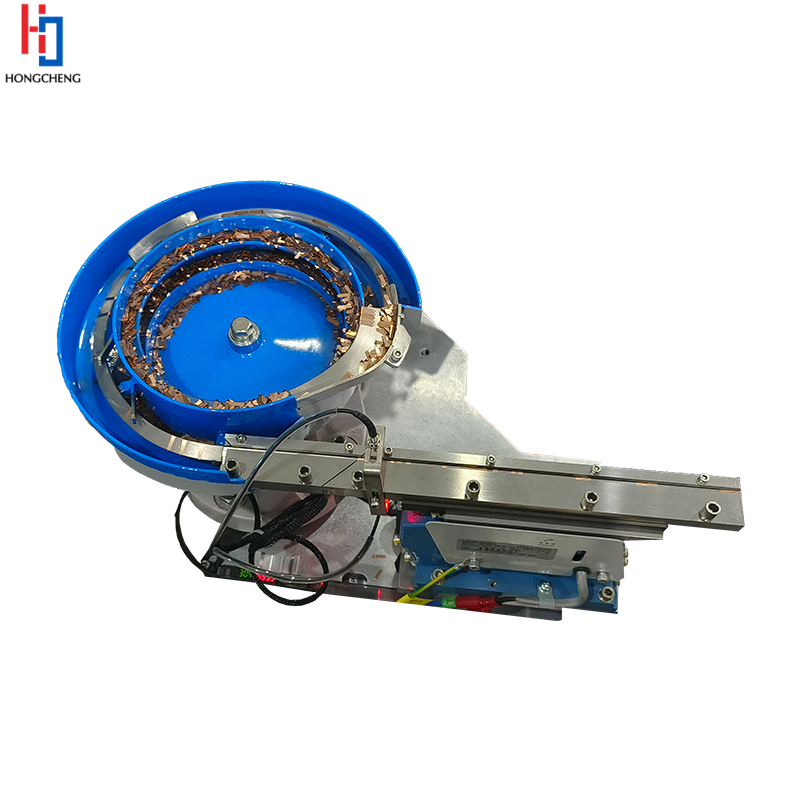

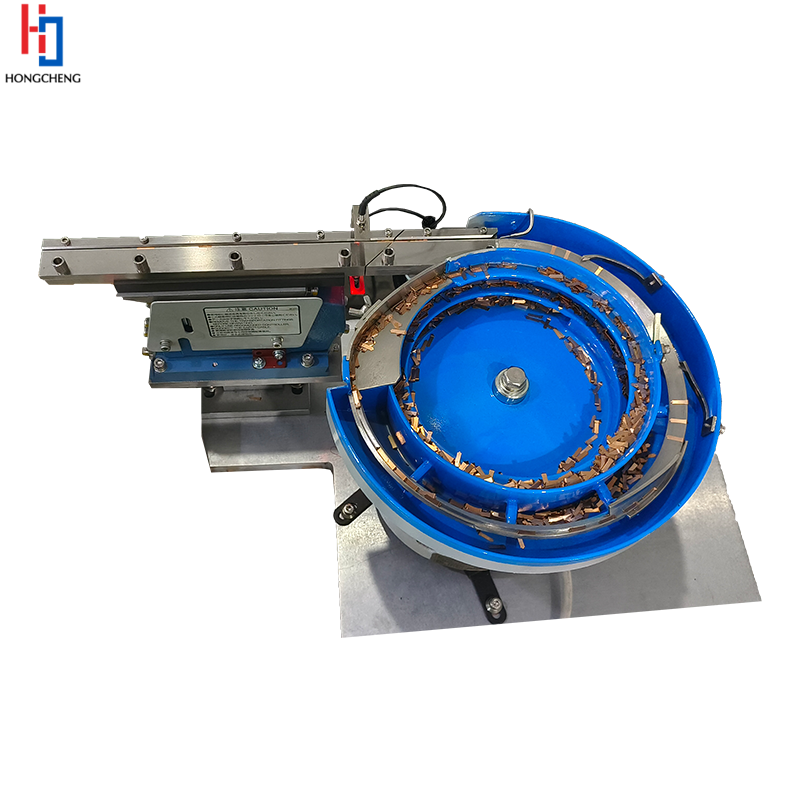

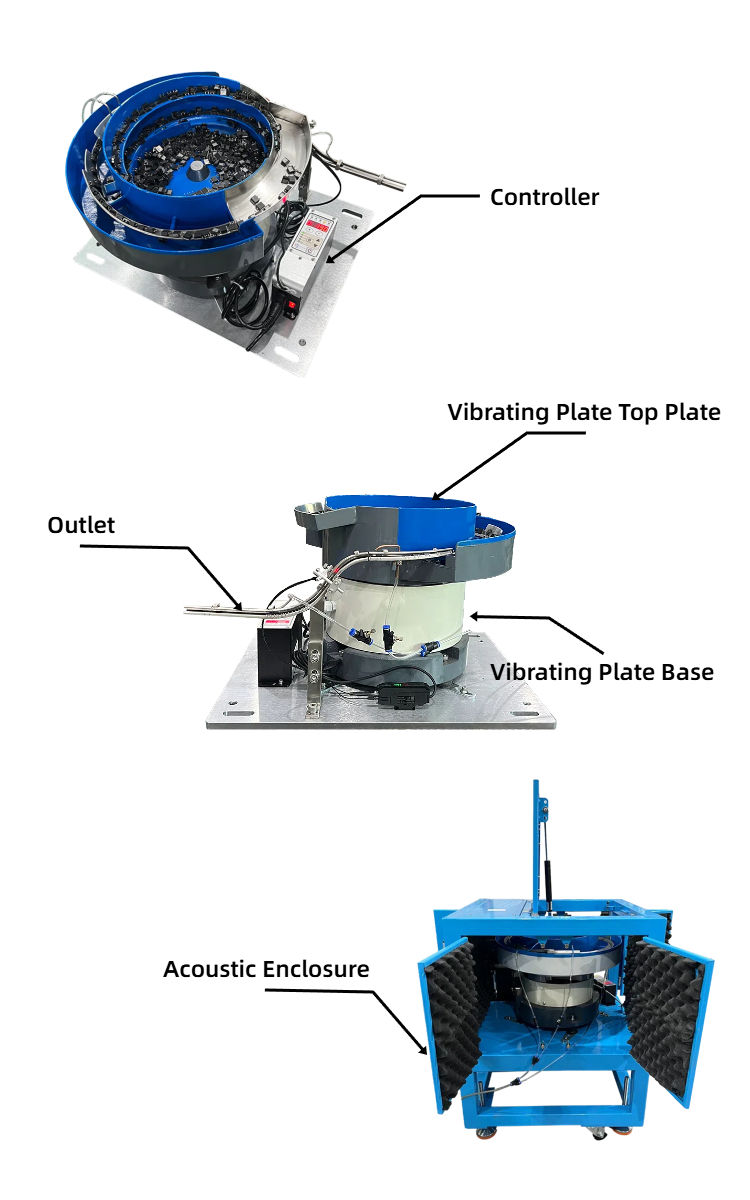

The vibratory bowl screw feeder system is an automation device that utilizes vibration to orient and transport screws or other hardware components. Through controlled vibration, it aligns the parts in a uniform and correct direction, then delivers them smoothly to the next production stage. The system typically consists of a bowl feeder, spring supports, and a drive unit. By minimizing manual handling, it significantly improves production efficiency, ensures consistent feeding accuracy, and reduces labor costs. Owing to these advantages, vibratory bowl screw feeder systems are widely applied in electronics, automotive, hardware, and other manufacturing industries.

Product advantages:

1. Vibratory feeder bowl for small metal pin can provide customized services of different specifications according to customer needs.

2. Vibratory bowl screw feeder system can accurately control feeding and reduce waste.

3. High precision vibratory bowl feeder for parts uses low noise operation and can provide a comfortable working environment.

Precautions before using high precision vibratory bowl feeder for parts:

Before we use the vibratory feeder bowl for small metal pin, we must first check the fastening of each component of the equipment to ensure that there is no looseness between the components. For the newly installed vibratory bowl screw feeder system, it is also necessary to test the machine to check whether the amplitude, current and voltage are normal. Adjust the amplitude, inclination and other parameters according to actual needs, and then install it correctly according to the instructions of the high precision vibratory bowl feeder for parts. It is also necessary to regularly add lubricating oil to the moving parts such as the bearings of the vibratory feeder bowl for small metal pin to ensure that it can operate normally.

Reasons for unstable power supply voltage of the vibratory feeder bowl for small metal pin:

The vibratory bowl screw feeder system mainly relies on power supply to maintain normal operation. If the power supply is unstable, it will cause changes in amplitude and affect the uniformity of feeding. If the factory voltage fluctuates greatly, the high precision vibratory bowl feeder for parts will work unstably. When we use multiple devices to share the same power supply, it will cause uneven current distribution and affect the power supply voltage. Another situation is that the power cord of the vibratory feeder bowl for small metal pin is aging or has poor contact, which will also affect the stability of the power supply. We can install a voltage stabilizer at the power supply end of the vibratory bowl screw feeder system to ensure voltage stability. Avoid sharing multiple high-power devices to reduce current fluctuations. The power cord should also be checked regularly to avoid poor power supply due to aging or looseness.

Company profile:

Shenzhen Hongcheng Automation Equipment Co., Ltd. is a manufacturer specializing in the production of automatic feeding equipment. Its products include automatic feeding vibration plates, automatic feeding bins, linear feeders, electronic control systems and vibration platforms. The company's products have been widely used in light industrial machinery, standard parts, connectors, bearing industries and other fields to help customers improve production efficiency.