Product introduction:

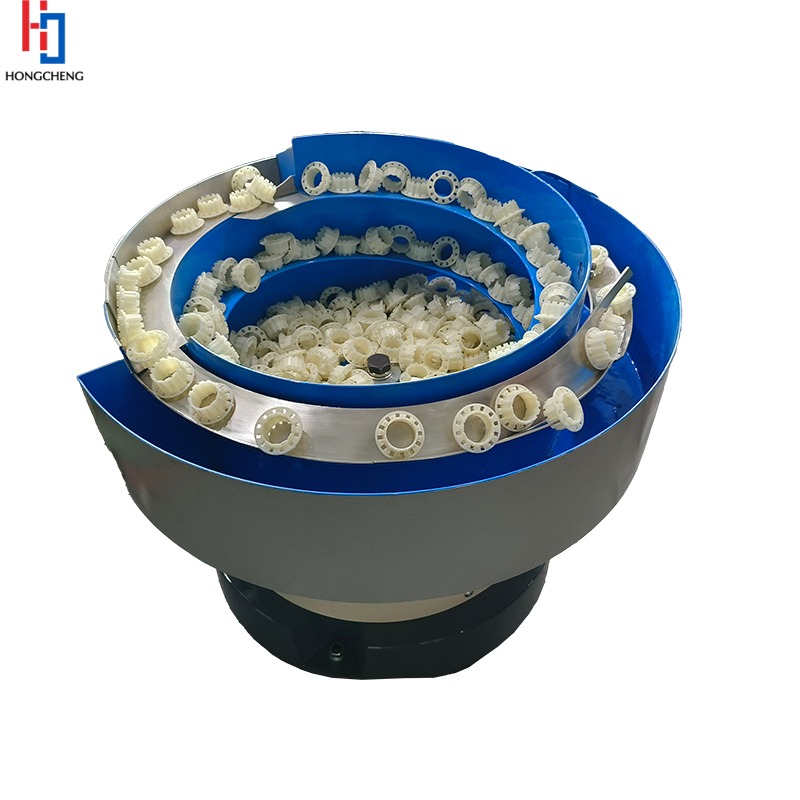

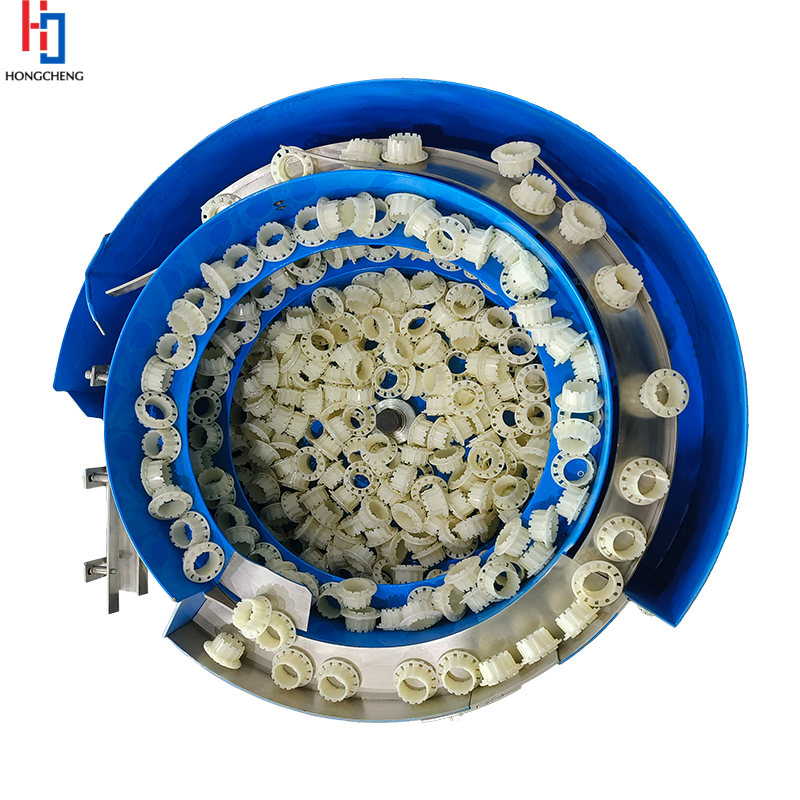

Vibrating bowl feeder for feeding rubber is an automatic feeding equipment. Vibratory bowl feeding system for rubber stoppers is specially used to convey small parts such as rubber stoppers. It mainly arranges the rubber stoppers in an orderly manner by vibration and conveys them to the designated position of the machine. Vibrating bowl feeder for feeding rubber is suitable for pharmaceutical, food, electronics and other industries. Vibrating bowl feeder for feeding rubber can effectively reduce manual operation, improve production efficiency, and allow materials to be conveyed accurately and stably.

Features of vibrating bowl feeder for feeding rubber:

1. Our rubber ring machine vibratory bowl feeder has a wide range of applicability and can handle rubber stoppers of different sizes and shapes.

2. Our rubber ring machine vibratory bowl feeder vibrates evenly during operation, is not easy to get stuck, and can ensure the continuity of work.

3. Compared with similar products, the energy consumption of vibratory Bowl feeding system for rubber stoppers is lower, and there is no pollution during actual operation.

Product application areas:

Vibrating bowl feeder for feeding rubber meets the highly precise and strict production processes in the pharmaceutical industry. Rubber ring machine vibratory bowl feeder plays an important role in the packaging and production of medicines. In the pharmaceutical packaging line, rubber stoppers are generally used to seal medicine bottles, such as glass bottles or plastic bottles. It can arrange the rubber stoppers in the correct direction and transport them to the packaging station. It can not only reduce labor costs, but also improve production efficiency. The food industry has high requirements for the hygiene and efficiency of automated equipment. Vibrating bowl feeder for feeding rubber can be used for food packaging, bottle cap sealing, etc. Many beverage products use rubber stoppers as bottle mouth seals. Rubber ring machine vibratory bowl feeder can automatically sort rubber stoppers and feed them into the packaging machine to complete the sealing operation. The vibratory bowl feeding system for rubber stoppers can avoid manual contact, reduce contamination risks, and meet food safety standards.

Working principle of the product:

The core working principle of the vibratory bowl feeding system for rubber stoppers is to generate power through electromagnetic vibration, so that the rubber stopper moves in the specified direction in the vibrating plate and finally enters the conveying track. The base of the vibrating bowl feeder for feeding rubber is equipped with an electromagnetic coil and a spring system. When the current passes through the coil, an alternating magnetic field is generated, which causes the vibrating plate to be attracted periodically and vibrate up and down. This high-frequency vibration pushes the rubber stopper to move forward on the plate. The frequency and amplitude of the vibration can be adjusted by the controller of the rubber ring machine vibratory bowl feeder, which can adapt to rubber stoppers of different specifications. The vibrating plate of the rubber ring machine vibratory bowl feeder also adopts a spiral track or a guide track design. When the rubber stoppers start to move up and down, the track guides them to be arranged in the correct direction and transported to the exit position.

FAQ:

1. How does the rubber ring machine vibratory bowl feeder work?

Our vibratory bowl feeding system for rubber stoppers uses a vibrating motor or electromagnetic vibration to generate power, so that the material moves along the track in the bowl and is transported out after being arranged in the correct direction.

2. What industries are suitable for rubber ring machine vibratory bowl feeder?

The vibratory bowl feeding system for rubber stoppers is mainly used in the pharmaceutical, food, electronics, automobile, hardware and other industries, and can also be used to automatically convey small parts.

3.What materials can the rubber ring machine vibratory bowl feeder convey?

The vibratory bowl feeding system for rubber stoppers can convey small parts such as rubber stoppers, screws, springs, electronic components, bottle caps, plastic parts, etc.

Company profile:

Shenzhen Hongcheng Automation Equipment Co., Ltd. is an enterprise focusing on automatic feeding systems (vibration plates), integrating R&D, sales and service. The company can provide a variety of automation equipment, including automatic feeding vibration plates, automatic feeding bins, linear feeders, electronic control systems and vibration platforms. These products are widely used in light industrial machinery, standard parts manufacturing, connector production, bearing industry and other fields.