Product description:

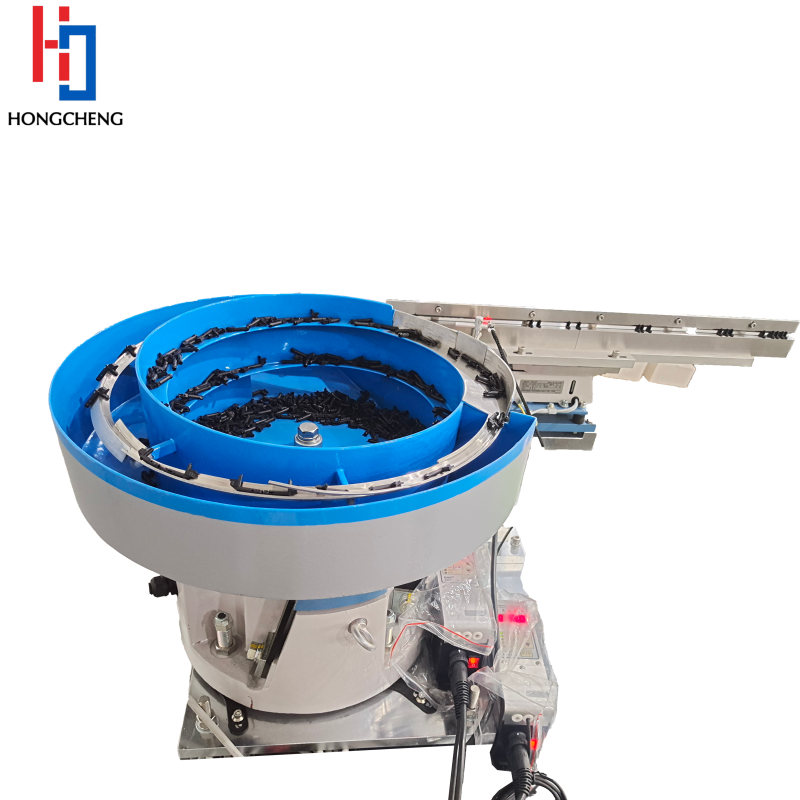

The vibrating feeding system for switch contacts is an automatic feeding device specially designed for efficient delivery and arrangement of micro switches. Vibrating bowl feeder for switch is suitable for industries such as electronic components, home appliance manufacturing, automotive electronics, and micro switches. It can be seamlessly connected with automatic assembly lines and robot systems to improve production efficiency. Automatic vibratory bowl feeders can be customized and optimized according to the size and shape of the micro switch to ensure smooth feeding.

Product application:

Our vibrating feeding system for switch contacts are widely used in products such as keyboards, mice, and home appliances. Automatic feeding equipment can speed up assembly. In the automotive industry: door switches, wiper switches, etc. require precise installation, and vibrating bowl feeder for switch can provide stable feeding and improve assembly quality. In addition, micro-opening can also be used for precision instruments, and automatic vibratory bowl feeders can ensure lossless feeding and improve product qualification rate.

How to optimize vibrating feeding system for switch contacts?

1. Vibrating bowl feeder for switch can ensure accurate operation of the motor through variable frequency speed regulation, phase adjustment, amplitude optimization and other methods. We also need to check the motor regularly to ensure that it is in good condition.

2. During the production process of automatic vibratory bowl feeders, we can adjust the height and angle of the vibrating trough according to needs to make it more in line with actual production conditions.

3. Finally, regularly maintain the various components of the vibrating feeding system for switch contacts to ensure that the equipment can operate stably and reduce the occurrence of faults.

How to maintain vibrating bowl feeder for switch?

When we use automatic vibratory bowl feeders, regular maintenance can make the equipment more stable and durable. Clean the bowl body and conveying channel of the vibrating bowl feeder for switch to reduce dust and bottle cap residue. Check the vibration system of the vibrating feeding system for switch contacts to ensure normal frequency and intensity. The rotating parts of the automatic vibratory bowl feeders should be lubricated regularly to reduce wear between parts, and check whether the screws and fasteners are loose to avoid affecting work efficiency.

Product parameters:

Product Name: | Vibrating Bowl Feeder for Switch | Package: | Wooden Case Package |

Voltage: | 220V | Certification: | |

Place of Origin: | Shenzhen, China | Color: | Customer Requirement |

Warranty: | 1 Year | Application: | Automotive Industry |

FAQ:

1. How to install the vibrating bowl feeder for switch?

We will provide detailed installation instructions and technical support for the vibrating bowl feeder for switch to ensure that you can put it into use quickly.

2. What is the service life of the automatic vibratory bowl feeders?

The specific life of the vibrating feeding system for switch contacts depends on the use environment, maintenance conditions and work intensity.

3. Can the vibrating bowl feeder for switch adapt to parts of different sizes?

Yes! If you have a large variety of parts, you can also use replaceable tracks or customized designs.

About us:

Shenzhen Hongcheng Automation Equipment Co., Ltd. focuses on automatic feeding systems. Its main products include vibration plates, aluminum plates, flexible platforms, double centrifugal plates, and feeders. It also develops and sells non-standard automation equipment and provides a full range of services. Our equipment is widely used in pharmaceutical, hardware and electrical appliances, plastics and rubber, electronic precision products and other industries to help companies improve production efficiency and achieve automation upgrades.