Product description:

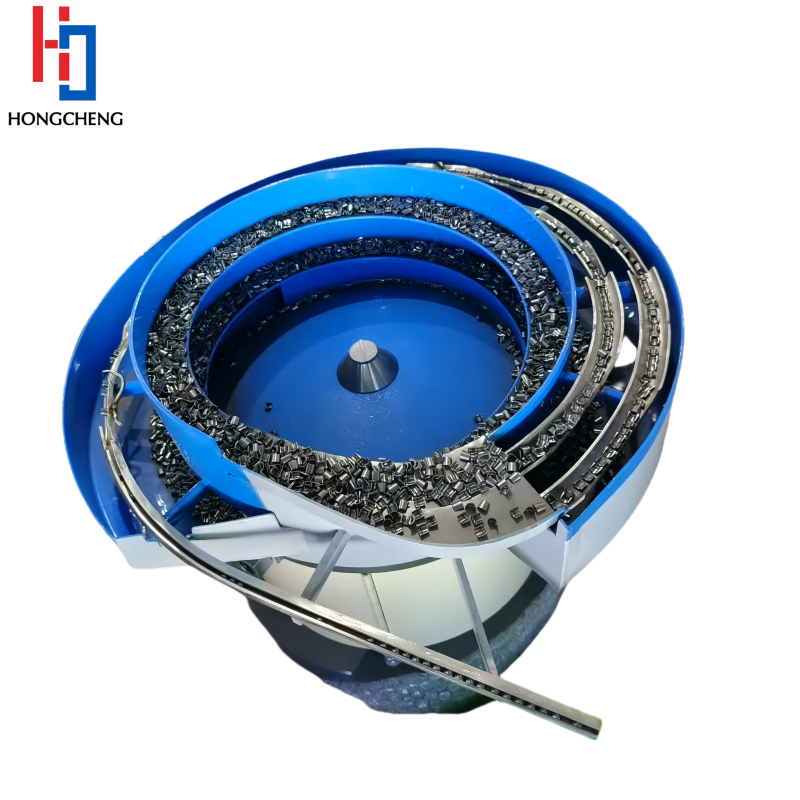

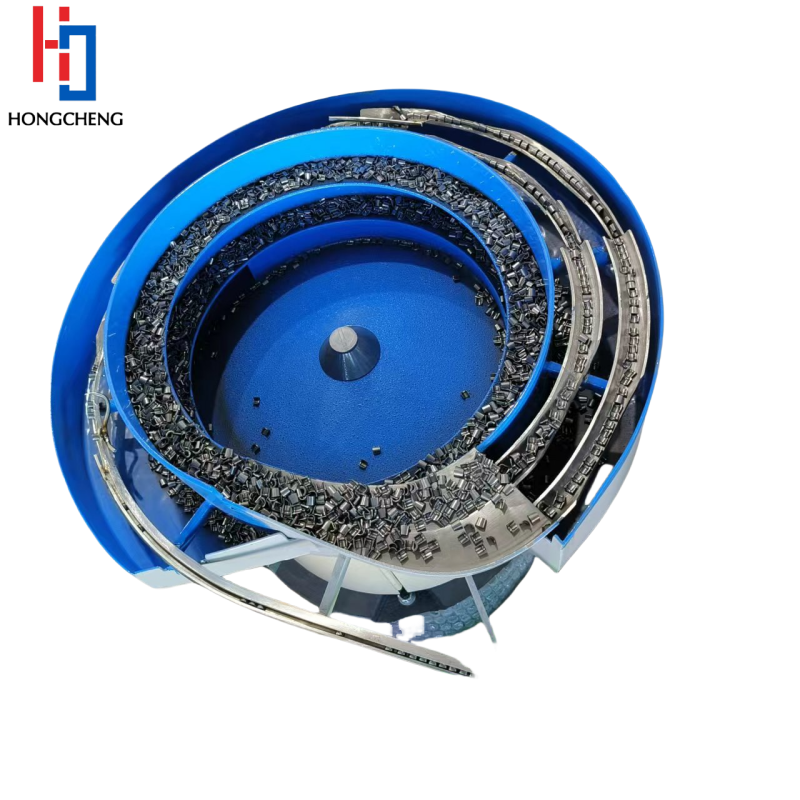

Vibratory bowl feeder is an automated feeding equipment that can efficiently and accurately convey various automotive parts such as screws, springs, connectors, bearings, etc. Vibratory bowl feeder for automotive clips arranges automotive parts neatly and conveys them to the next process through the principle of vibration. It is widely used in industries such as automobile manufacturing and assembly lines.

Advantages of large screw vibrating bowl feeder:

1. Our vibratory bowl feeder for automotive clips has stable feeding and strong adaptability, and can be customized according to the shape and size of different parts.

2. Automatic screw feeder machine uses highly wear-resistant materials, operates smoothly, has a long service life, and has low maintenance costs.

3. Large screw vibrating bowl feeder can be seamlessly connected with automatic assembly lines and robot systems to improve production efficiency and reduce manual intervention.

Why choose our vibratory bowl feeder for valve?

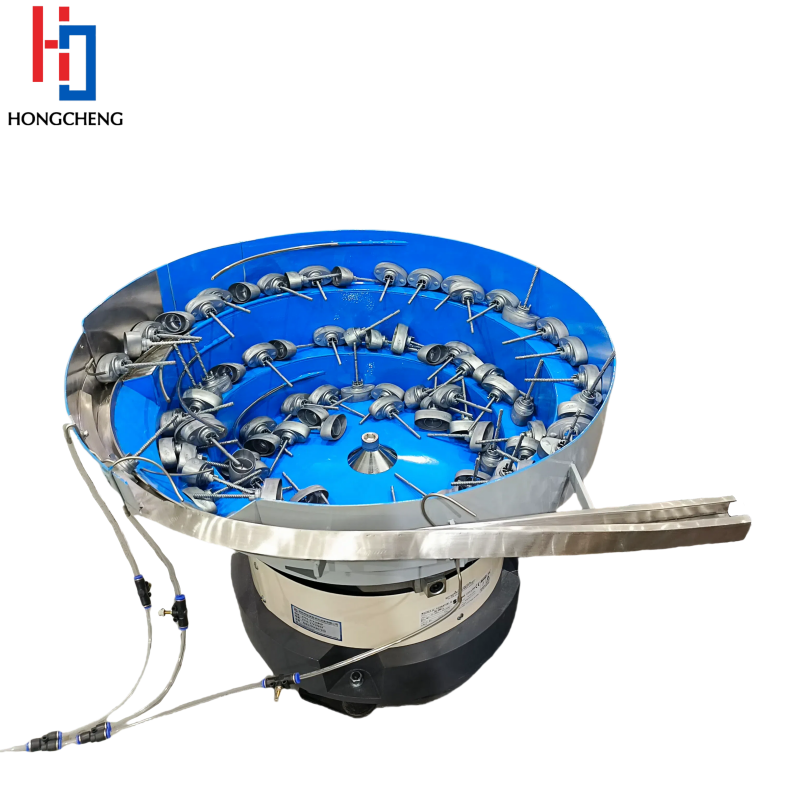

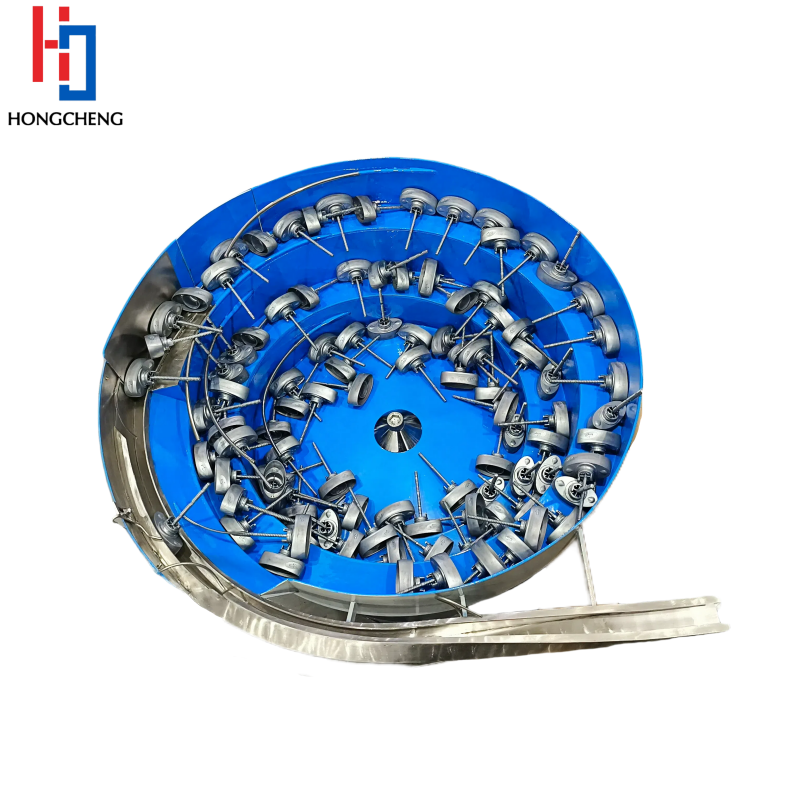

1. Auto parts are generally small in size and complex in shape, such as screws, springs, terminals, seals, etc. Traditional manual feeding is prone to errors and inefficient. Our vibratory bowl feeder for automotive clips can automatically arrange parts and accurately convey them, making the production line smoother and greatly improving the speed of automated assembly.

2. Automatic screw feeder machine and vibratory bowl feeder for valve can run stably for a long time without frequent manual intervention, which not only reduces labor costs but also avoids problems caused by human errors.

3. In the process of automobile assembly, if the feeding is not accurate, it may cause wrong installation or missing parts, affecting the quality of the whole vehicle. Large screw vibrating bowl feeder can ensure that the parts are arranged in the correct direction and accurately conveyed to the specified position, reducing assembly errors and improving the qualified rate of products.

Application of vibratory bowl feeder for valve:

Our automatic screw feeder machine can be used to convey small precision parts such as resistors, capacitors, and automotive parts. In automobile manufacturing, many parts are small in size and complex in shape, such as screws, springs, terminals, and seals. Large screw vibrating bowl feeder can ensure the directional sorting and uniform delivery of these parts, improving production efficiency and assembly accuracy. Many small parts in home appliance manufacturing require efficient feeding, such as buttons, plastic fasteners, switch parts, etc. Our vibratory bowl feeder for valve also helps automated equipment to complete assembly smoothly and improve production line efficiency.

Product parameters:

Applicable Industries: | Auto Parts | Product Name: | Automatic Screw Feeder Machine |

Voltage: | 220V | Certification: | |

Place of Origin: | Shenzhen, China | Bowl material: | Stainless Stell |

Warranty: | 1 Year | Condition: | New |

FAQ:

1. Is the noise of automatic screw feeder machine loud?

Our feeder uses an optimized vibration system with low noise, but the specific volume depends on the operating speed and part material.

2. Does large screw vibrating bowl feeder require frequent maintenance?

The maintenance of vibratory bowl feeder for valve is relatively simple, mainly including regular cleaning of the bowl and track, etc.

3. Will vibratory bowl feeder for automotive clips get stuck during operation?

Under normal circumstances, there will be no jamming, because the vibration frequency and track design of the feeder are optimized to ensure smooth delivery of parts.

About us:

Shenzhen Hongcheng Automation Equipment Co., Ltd. is a manufacturer specializing in the production of automatic feeding systems, providing vibration plates, aluminum plates, flexible platforms, double centrifugal plates, feeders and other equipment, and undertakes the research and development, sales and after-sales service of non-standard automation equipment. Our equipment is suitable for multiple industries, such as pharmaceuticals, hardware and electrical appliances, plastics and rubber, connectors, batteries, etc., providing customers with stable and reliable automation solutions.