Product introduction of centrifugal feeders in automation:

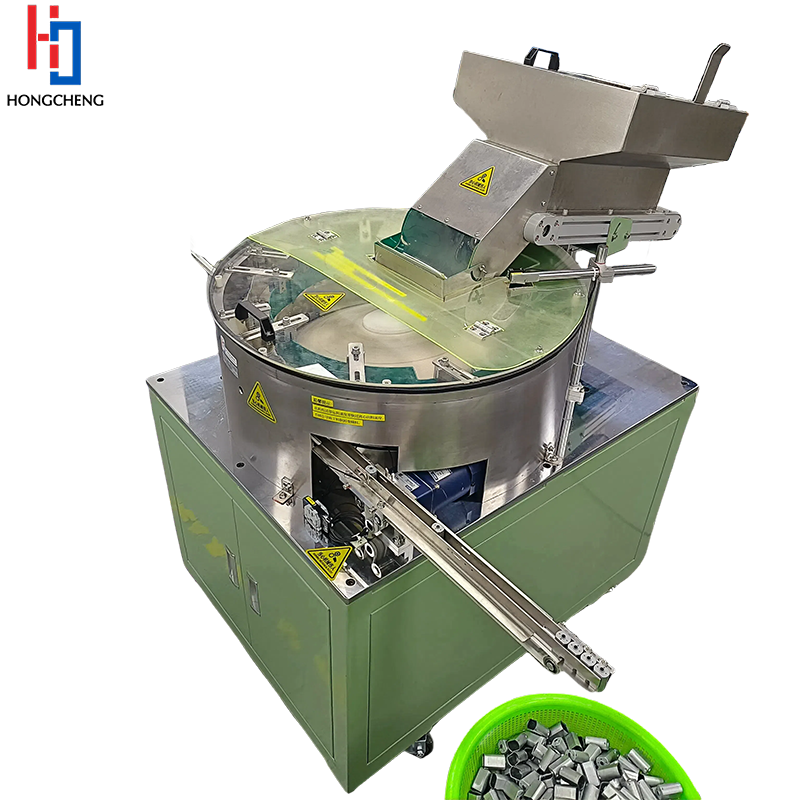

Centrifugal separators with integral feeder is an efficient and automated feeding system designed for the precise distribution and delivery of electric motor housings. Centrifugal separators with integral feeder uses the principle of centrifugal force to evenly distribute and feed the electric motor housings into the production line, ensuring the accurate orientation and position of each housing. Centrifugal feeder rotary bowl systems has a compact overall design and is easy to operate. It can not only effectively improve the speed and efficiency of the production line, but also reduce manual intervention and reduce the failure rate.

Product advantages of centrifugal feeder rotary bowl systems:

Centrifugal separators with integral feeder has a high degree of automation, which can reduce manual intervention and operation, reduce the occurrence of human errors, and improve the operating efficiency and safety of the production line.

Centrifugal separators with integral feeder has a simple structure, exquisite design, high-quality materials and precision processing technology, and is strong and durable as a whole, reducing the occurrence of failures. Centrifugal separators with integral feeder's simple structure is also easier to maintain and clean, reducing downtime.

Centrifugal feeder rotary bowl systems is small and flexible, saving floor space, and is suitable for use in factories with limited space.

Working principle of centrifugal feeder rotary bowl systems:

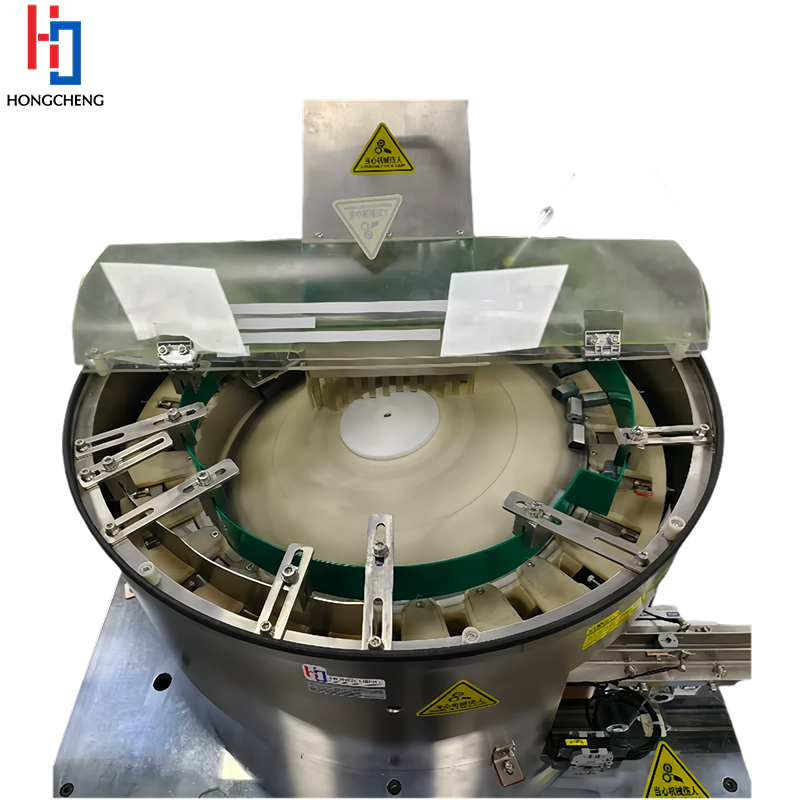

Centrifugal feeder rotary bowl systems uses centrifugal force to push the scattered motor housings to the feeding track outside the equipment through a high-speed rotating turntable or centrifugal wheel. There are multiple grooves installed on the turntable of centrifugal feeders in automation, which can accommodate electric motor housings of different sizes and shapes. During the rotation process, the motor housings are evenly distributed and accurately guided to the appropriate direction by centrifugal force, ensuring that each motor housing is smoothly fed into the subsequent production links according to the predetermined trajectory. By adjusting the speed and track design, centrifugal feeders in automation can flexibly adapt to motor housings of different sizes, ensure the stability and efficiency of the feeding process, and greatly improve the automation level of the production line.

Services we can provide:

HONGCHENG is committed to providing customers with customized centrifugal feeders in automation products to meet the needs of different production environments and materials. Whether it is to increase the feeding speed, reduce noise, or accurately convey special materials, our design team will design and manufacture the most suitable centrifugal feeders in automation for your product according to your production process and specific product size requirements. We also provide an automation system for the entire production line, which can be adapted to other production equipment to improve overall production efficiency.

About us:

Shenzhen Hongcheng Automation Equipment Co., Ltd. is customer-oriented and is committed to providing efficient and intelligent non-standard automation equipment. Our main products include centrifugal loaders, bowl feeders and flexible feeding systems, etc. All equipment can be customized according to customer production needs and sizes. With leading technology, exquisite craftsmanship and excellent service, we provide customers with the best production efficiency and cost-effectiveness, helping customers gain an advantage in global competition.