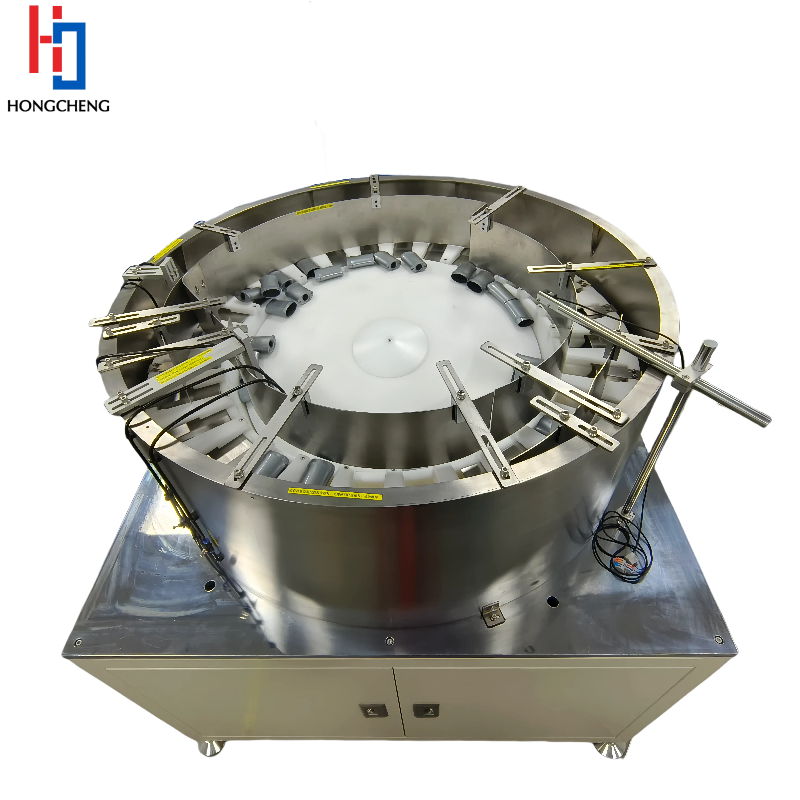

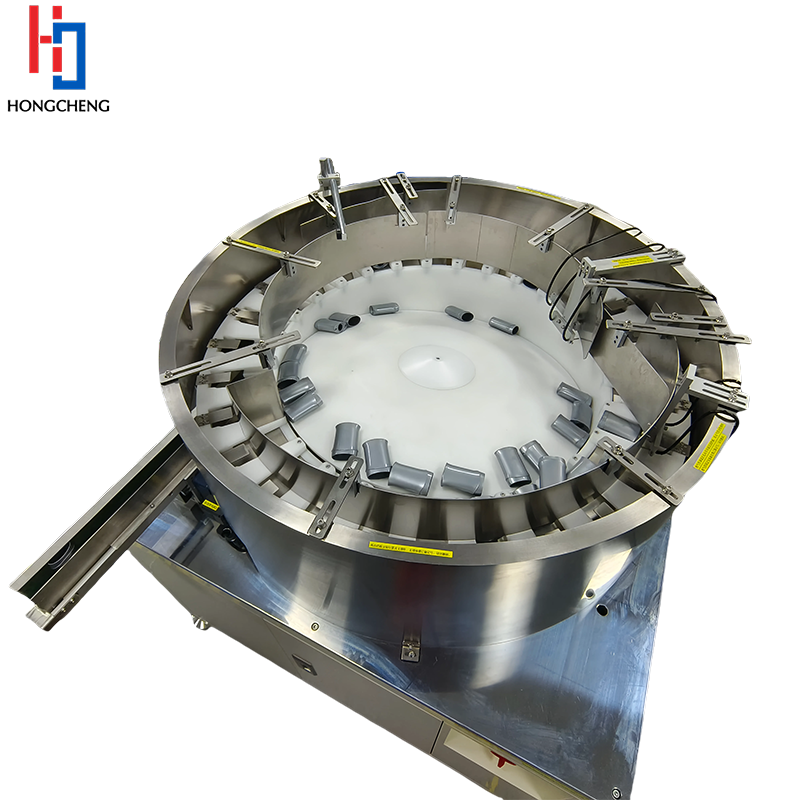

Product introduction of cosmetics centrifugal feeder:

Our glass bottle centrifugal feeder is designed for the cosmetics industry and is mainly used to efficiently transfer cosmetic bottles on the production line. The centrifugal feeder system for plastic bottles is compact and suitable for use in factories. It uses centrifugal force to stably transport bottles to designated locations, saving manpower and improving production efficiency. The centrifugal feeder system for plastic bottles has precise conveying capacity and can ensure that the bottles do not collide. It is suitable for the automated production and packaging lines of cosmetic bottles.

Product advantages of cosmetics centrifugal feeder:

Glass bottle centrifugal feeder can operate efficiently in a limited space, with a small footprint, making full use of factory space and adapting to different production line layouts.

Centrifugal feeder system for plastic bottles uses a centrifugal force transmission system to smoothly transport bottles, avoid collisions between bottles, ensure the integrity of bottles, and reduce product loss.

Cosmetics centrifugal feeder can greatly improve production efficiency and improve the smoothness of production lines by automating feeding and reducing manual intervention.

How does glass bottle centrifugal feeder work?

Our glass bottle centrifugal feeder works on the principle of centrifugal force to transport cosmetic bottles from low to high. After the bottle enters the machine through the feed port, the centrifugal wheel rotates at high speed, generating strong centrifugal force, pushing the bottle upward along the wall of the machine. During operation, the bottle can be stably transferred to the conveyor belt or other material receiving system without damage. Centrifugal feeder system for plastic bottles is suitable for the fine conveying of cosmetic bottles, and can efficiently and gently complete the bottle feeding task, improving the automation and production efficiency of the production line.

Product parameters of cosmetics centrifugal feeder:

Place of Origin: | Shenzhen, China | Brand Name: | HONGCHENG |

Model Number |

| Product Name: | Glass bottle centrifugal feeder |

Warranty: | 1 Year | Applicable Industries: | Manufacturing Plant, Energy & Mining |

Voltage: | 220V | Color: | Customer Requirement |

Material characteristics: | Good processing performance and high toughness | Package: | Wooden case package |

Payment term: | T/T 30% Deposit and balance before shippment | Service: | Spare Parts and Technology Support |

About us:

Shenzhen Hongcheng Automation Equipment Co., Ltd. specializes in the R&D, sales, and service of non-standard automation equipment, particularly bowl feeder systems. We leverage advanced technology, precise design, and high-quality production to solve automation challenges with custom solutions.