Product introduction:

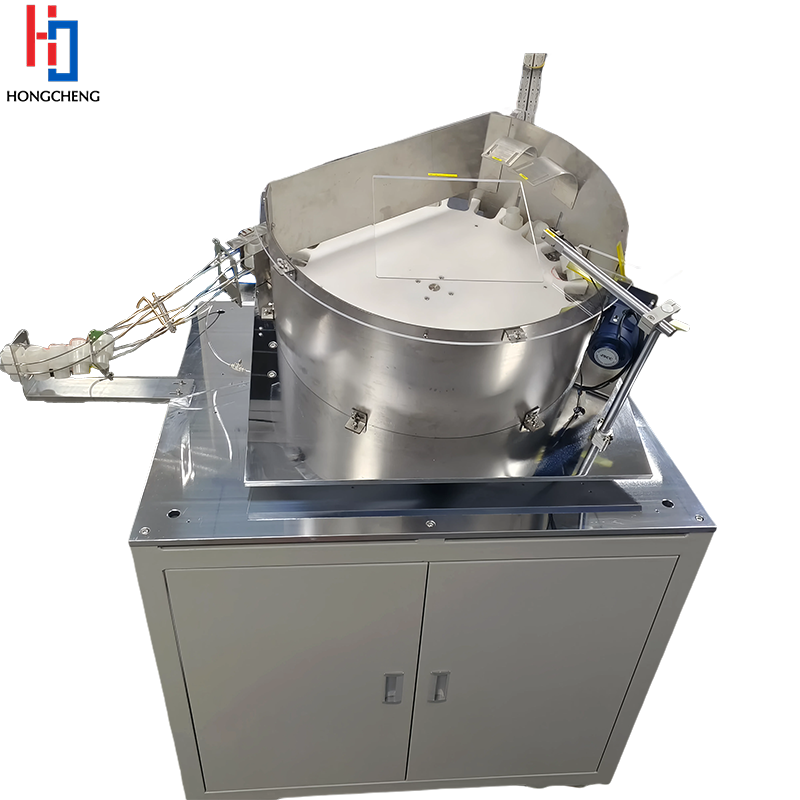

Centrifugal feeder & rotary bowl systems is a kind of equipment used to convey orient plastic bases. Performance feeders centrifugal feeder adopts advanced centrifugal feeding technology, which can quickly and accurately arrange orient plastic bases neatly and convey them to the discharge port in the set direction. Centrifugal feeder for orienting coffee pods can reduce manual intervention and make the production process of orient plastic bases smoother. It is widely used in electronic equipment, home appliances, automotive parts and other industries.

Product advantages:

1. Centrifugal feeder & rotary bowl systems are made of high-quality materials, wear-resistant and corrosion-resistant, ensuring long-term use without deformation and damage.

2. Performance feeders centrifugal feeder adopts advanced feeding technology, which allows orient plastic bases to be automatically arranged and positioned in a short time.

3. Centrifugal feeder for orienting coffee pods uses low-noise and quiet motors to provide a comfortable working environment.

Working principle of the product:

Centrifugal feeder & rotary bowl systems adopts the principle of centrifugal feeding, and mainly realizes automatic feeding through centrifugal rotation drive, guided sorting and other methods. During the centrifugal rotation drive process, the feeding bowl inside the performance feeders centrifugal feeder will move the orient plastic bases along the bowl wall under the action of high-speed rotation and enter the preset feeding track. The centrifugal feeder for orienting coffee pods has a built-in track sorting mechanism, which allows the orient plastic bases to be arranged in the correct direction and smoothly enter the next process.

Product maintenance:

During the use of the centrifugal feeder & rotary bowl systems, it is necessary to clean it regularly. Use a dry cloth or air gun to clean the remaining plastic debris in the bowl. Do not use corrosive cleaning agents to damage the surface of the equipment. Also check the motor operation status of the performance feeders centrifugal feeder regularly to check whether its vibration is uniform and whether the operation status is stable. If the power connection is unstable, check whether the line is loose in time. You can also add lubricating oil to the bearings and rotating parts of centrifugal feeder for orienting coffee pods to reduce wear between parts and extend its service life.

Company profile:

Shenzhen Hongcheng Automation Equipment Co., Ltd. focuses on the design and production of automatic feeding systems (vibration plates). It is a modern enterprise integrating r&d, sales and service. The company has advanced production equipment and a professional technical team, and the product quality is strictly controlled. We have established a complete after-sales system to provide fast and efficient services. The main products include automatic feeding vibration plates, automatic feeding bins, precision aluminum plates, flexible platforms, centrifugal equipment, etc., which are widely used in oil-containing bearings, nozzles, buttons, zippers, cork, pharmaceuticals, hardware, batteries, medical devices and other fields.