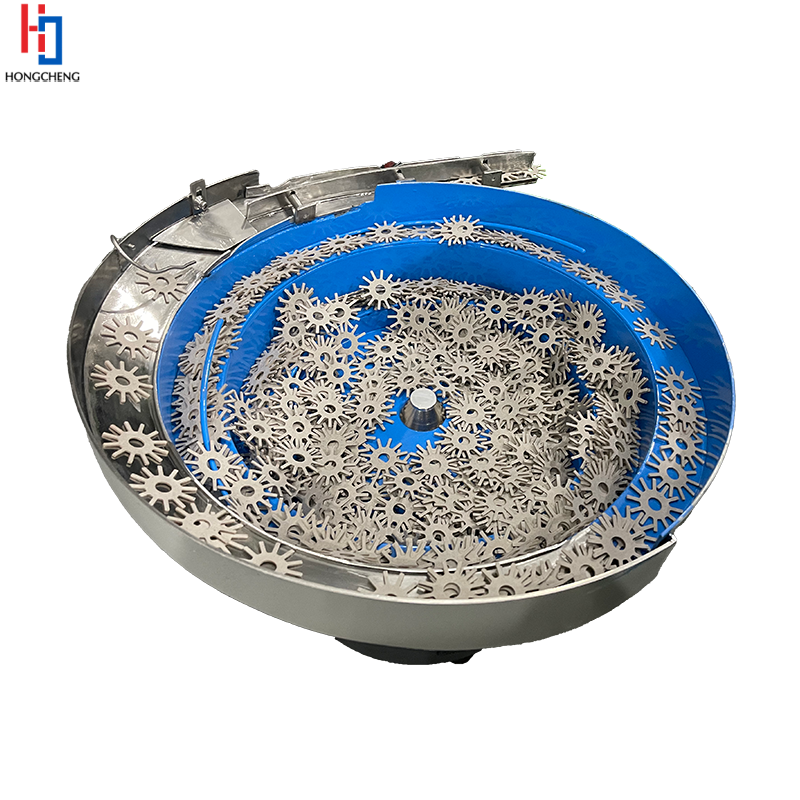

Product overview:

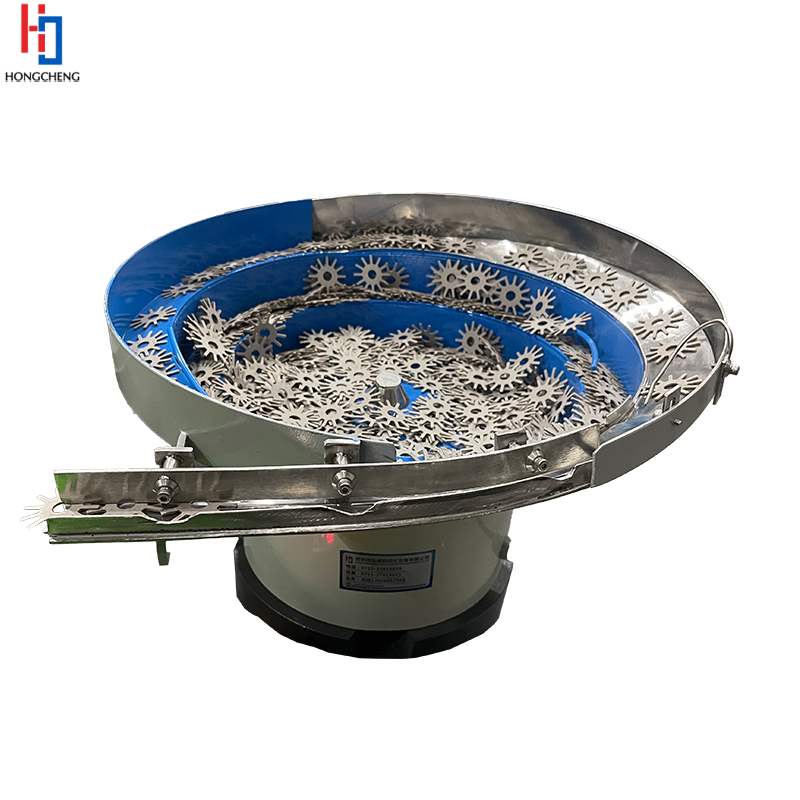

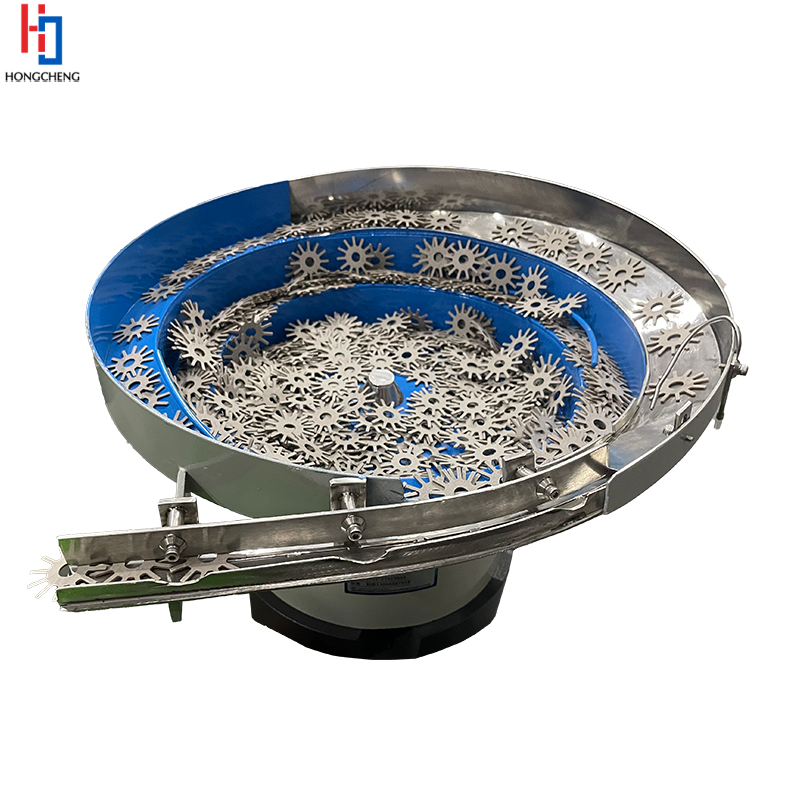

Vibratory bowl feeders for the automotive sector are automatic feeding equipment used in the automotive industry. Its core function is to arrange materials in an orderly manner in the bowl-shaped track through the principle of vibration, and transport them to the production line or other automated equipment in a specified direction. Compared with the traditional manual feeding method, the automotive radar vibratory bowl feeder can reduce labor costs, and the operation of the multipurpose vibratory feeder bowl is also relatively simple. You only need to turn on the power and adjust the vibration frequency to automatically feed the materials.

Product advantages:

1. Multipurpose vibratory feeder bowl use automatic feeding to ensure the continuity of work and effectively improve work efficiency.

2. Automotive radar vibratory bowl feeder can avoid scratches or damage to parts during the conveying process.

3. The motor of the multipurpose vibratory feeder bowl has low energy consumption, which can reduce power consumption.

How to choose vibratory bowl feeders for the automotive sector?

Before choosing an automotive radar vibratory bowl feeder, we need to determine the type and size of automotive parts. Different types of automotive parts have different design and parameter requirements for the multipurpose vibratory feeder bowl. For example, round, spiral or directional bowls May be more suitable for small parts such as screws and springs. The material of the vibratory bowl will also affect the durability and stability of the vibratory bowl feeders for the automotive sector. For example, aluminum alloy is more suitable for products with light weight and low wear resistance. The feeding speed will directly affect the production efficiency, but too fast a speed will cause parts to tip over or pile up. We also need to consider the compatibility and scalability of the automotive radar vibratory bowl feeder. In the automotive manufacturing industry, the production line May need to replace parts of different specifications to see if it supports multiple parts and whether it can be adapted to other equipment.

How to solve the problem of unstable feeding?

1. Regularly check the vibrating electromagnet, circuit and spring sheet of the multipurpose vibratory feeder bowl to maintain normal working condition.

2. Regularly clean the vibratory bowl feeders for the automotive sector to avoid dust or oil that affects the vibration effect.

3. The feeding track angle and width need to be adjusted to allow parts to flow smoothly.

4. Select appropriate feeding parameters.

Company profile:

Shenzhen Hongcheng Automation Equipment Co., Ltd. Focuses on the research and development, sales and service of automatic feeding systems (vibration plates) and non-standard automation equipment. Our products are widely used in many industries. We have a complete after-sales service system and professional team to ensure that customers can communicate and solve any problems in the process of use in time. The main products include automatic feeding vibration plates, automatic feeding bins, precision aluminum plates, flexible platforms, centrifugal equipment, etc.