What is Auto Part Vibratory Bowl Feeder? Many friends who have not been exposed to automation equipment may feel unfamiliar, but if you have seen the small parts on the production line arranged neatly and automatically sent to the next process, then what you see is probably Auto Part Vibratory Bowl Feeder working silently. Auto Part Vibratory Bowl Feeder is an automation equipment that uses the principle of vibration to arrange and transport scattered parts in an orderly manner. It is widely used in various industries such as electronics, medical, automobiles, hardware, plastics, etc. Auto Part Vibratory Bowl Feeder puts all kinds of messy small parts in a line and sends them to the robot or assembly station, saving a lot of manpower and greatly improving efficiency.

Is Vibrating bowl feeder for Plastic really that magical? The answer is yes. It can not only be customized according to the size, shape, and material of the product, but also achieve precise feeding speed control and maintain stable operation in high-speed operations. For example, on an assembly line of electronic components, if there is no Vibrating bowl feeder for Plastic, the manual placement of each part will not only be inefficient, but also have a high error rate. With Vibrating bowl feeder for Plastic, you only need to pour the bulk parts in, and leave the next thing to it. It can automatically identify the direction, screen qualified parts, remove unqualified parts, and even cooperate with the visual inspection system in one go.

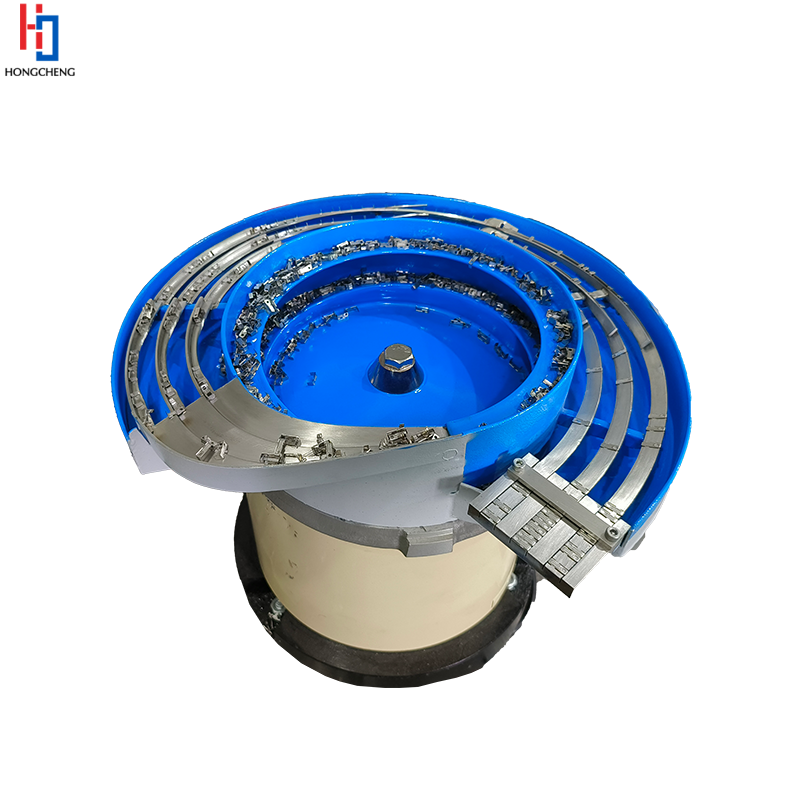

Our HONGCHENG factory specializes in the production of various types of Vibrating bowl feeder for Plastic, including vibration plates, linear feeders, controllers, bases and other supporting systems, which can be customized according to different application requirements of customers. From microelectronic components to complex hardware parts, we can provide customers with complete integrated feeding solutions. Our Vibrating bowl feeder for Plastic is widely used in the production lines of many well-known companies at home and abroad, helping customers to achieve automation and upgrade of the industrial chain and improve efficiency.

In terms of production strength, we have an independent design team, experienced assembly technicians and precision processing equipment. Each Vibratory Bowl Feeder undergoes rigorous testing before leaving the factory to ensure that it can be plug-and-play and run stably for a long time on the customer's production line. Our factory is equipped with modern equipment such as CNC machining centers, laser cutting machines, and high-precision testing instruments, which not only ensures manufacturing accuracy, but also shortens the delivery cycle. In addition to standard products, we also undertake the design of feeding systems for various special-shaped parts, which are truly customized on demand, flexible and efficient.

If your production line is still relying on a large number of manual labor, or encounters problems such as low feeding efficiency and difficult direction identification, you might as well try our Vibratory Bowl Feeder, maybe it is the "invisible hand" you need. If you are interested in our Vibratory Bowl Feeder, please feel free to contact us. We are happy to provide you with prototype testing, solution design and technical support to make production easier and more efficient.