Have you ever thought about how an automated production line can achieve "non-stop"? The machine cannot find parts by itself or queue up by itself, so it is the turn of the "feeding system" to shine. Simply put, the feeding system, also called the feeding system, is to continuously "feed" the next process. It is responsible for lining up and delivering parts of various sizes and shapes one by one to ensure the stable and efficient operation of the entire production line.

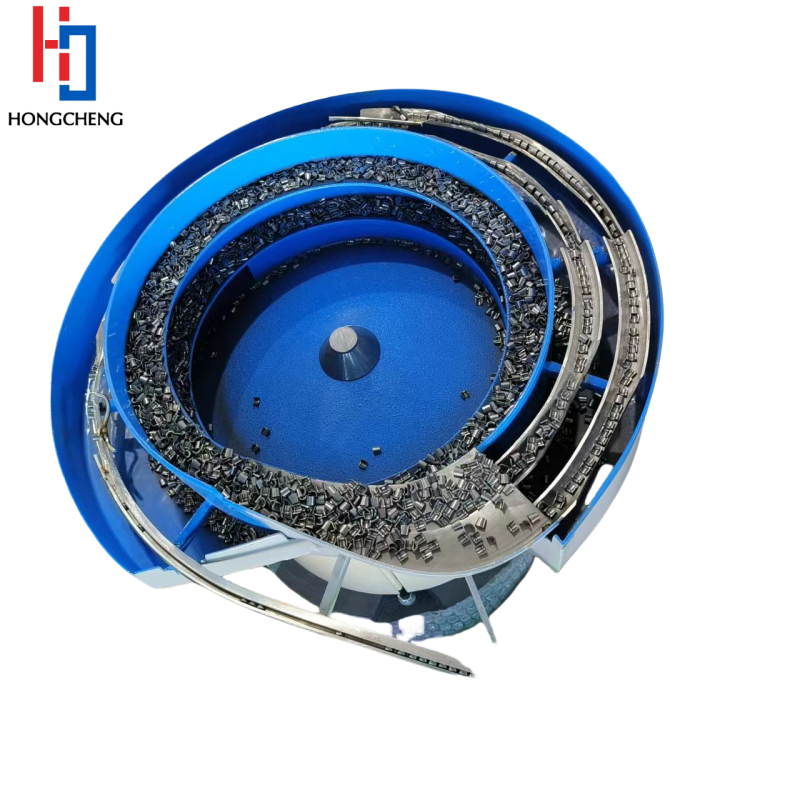

Vibratory Bowl Feeder is a star player in the feeding system, especially in the hardware, electronics, medical, toys, and packaging industries. Almost wherever there are parts, there are Vibratory Bowl Feeder. The working method of Vibratory Bowl Feeder is also very interesting. It relies on vibration to make the parts spiral up on a bowl-like track, and finally come out neatly and orderly, which is very relaxing to watch. Someone joked: "Vibratory Bowl Feeder is simply a little expert in queuing in the parts industry."

HONGCHENG specializes in the production of this kind of Vibratory Bowl Feeder, with a wide range of products, high stability, and wide application. The most important thing is that we don't do the same, we do "tailor-made". If you give us a sample, we can design a unique feeding solution for you. What do your screws look like? How light and small is the capacitor you use? Does the part have holes or is it magnetic? No problem, we can determine the track, select the vibrator, and design the Vibratory Bowl Feeder control system based on these characteristics.

Many customers came to us with samples and said worriedly: "Our shape is too special, it should not be possible to feed it?" We smiled and said, "How do you know if you haven't tried it?" After trying it, customers often exclaimed: "Can it be like this?" Don't look at the small parts as inconspicuous, it is very particular to really arrange them neatly, send them accurately, and not jam. We not only make bowls, but also make vibration plates, linear feeders, and controllers. The whole system can be equipped, which is really worry-free and labor-saving.

HONGCHENG's factory is equipped with complete production lines such as CNC processing, laser cutting, assembly and debugging. The whole process is done by ourselves, and we control the quality ourselves. Each Vibratory Bowl Feeder is tested for a long time before leaving the factory to ensure that it does not need to be adjusted repeatedly when it arrives in the hands of customers. Don't be afraid of problems, we have remote technical support, video teaching, door-to-door service when necessary, and full tracking.

In addition to conventional equipment, we are better at non-standard customization. If you have limited space, we can design a mini version for you; if you want to load multiple parts at the same time, we can also customize a multi-station feeder. No matter how complex the needs are, we can find a way to achieve them here.

In today's increasingly popular automation, Vibratory Bowl Feeder may not seem to be the most eye-catching protagonist, but it is an important part of silently supporting the stable operation of the entire production line. If you haven't used it yet, or you are still using old equipment that is stuck every day, why not come and talk to us, maybe a smart Vibratory Bowl Feeder that suits you can help you improve your efficiency to a new level. Let's make production simpler, more efficient and more interesting together!