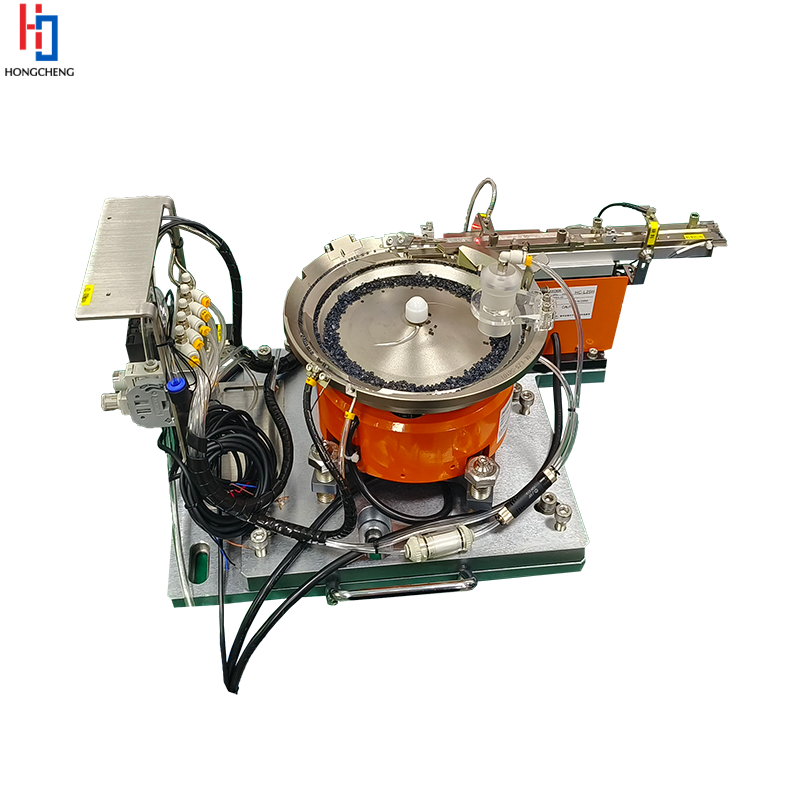

Product description:

Rubber stopper vibration feeder bowl is a kind of equipment specially used for conveying rubber core aluminum. It adopts bowl design and uses the principle of vibration to convey rubber core aluminum safely and smoothly to the next process. Different industries have different requirements for vibratory bowl feeder for rubber seal o-ring. We provide exclusive customized solutions for it to ensure that rubber stopper vibration feeder bowl meets the requirements of customers' production lines.

Product highlights:

1. Rubber stopper vibration feeder bowl adopts special design, which is more stable than traditional feeders.

2. Vibratory bowl feeder for rubber seal o-ring uses high-quality materials, which is not only corrosion-resistant, but also lighter and more durable.

3. Aluminum vibratory bowl feeder for rubber o-ring can adjust its vibration frequency and is suitable for rubber core aluminum of different specifications.

How do I install the product?

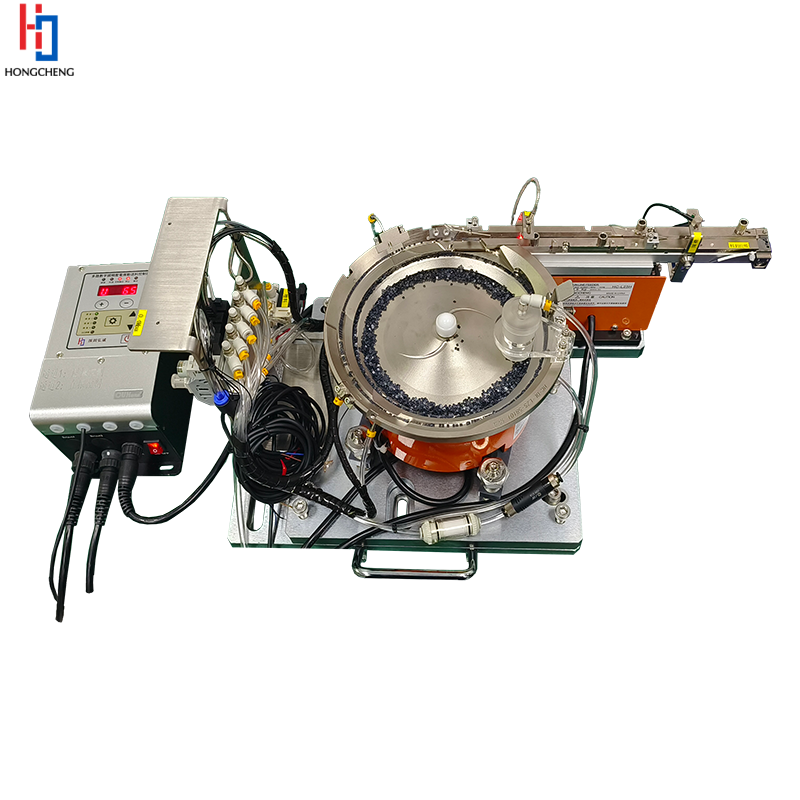

When we install the vibratory bowl feeder for rubber seal o-ring, we must first confirm whether the installation ground is flat, and prepare some installation tools. Unpack and check whether the rubber stopper vibration feeder bowl is damaged. First fix the base of the vibratory bowl feeder for rubber seal o-ring, then install the whole, adjust the outlet of the aluminum vibratory bowl feeder for rubber o-ring, and finally make electrical connections.

Daily maintenance of rubber stopper vibration feeder bowl:

During the operation of the aluminum vibratory bowl feeder for rubber o-ring, impurities such as dust, oil, and debris May accumulate inside the bowl or on the feeding track, affecting the smoothness of feeding. So we need to clean the bowl and feeding track regularly. The vibration motor and electromagnetic coil of the aluminum vibratory bowl feeder for rubber o-ring are the core components of the bowl feeder. We need to check the operation of the motor regularly. If abnormalities are found, we need to stop the machine for inspection, reinforcement or replacement of parts in time. Regular inspection and adjustment can adjust the amplitude and feeding speed to ensure smooth conveying of rubber core aluminum.

Company profile:

Shenzhen Hongcheng Automation Equipment Co., Ltd. is an enterprise focusing on automatic feeding system (vibration plate), integrating r&d, sales and service. The company can provide a variety of automation equipment such as automatic feeding vibration plate, automatic feeding bin, linear feeder, electronic control system and vibration platform. These products are widely used in many fields such as light industrial machinery, standard parts manufacturing, connector production, bearing industry, etc.