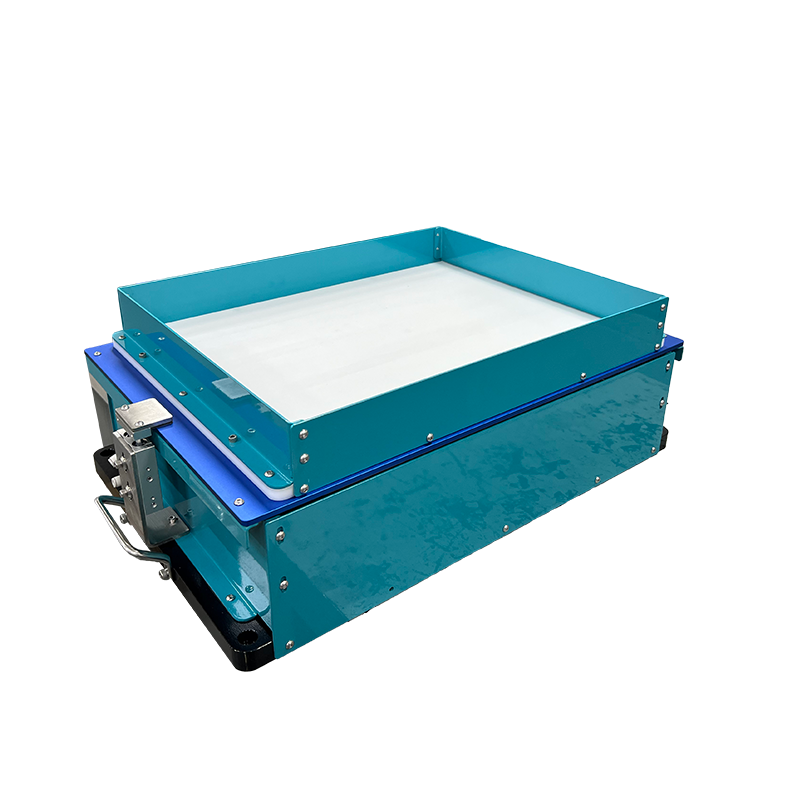

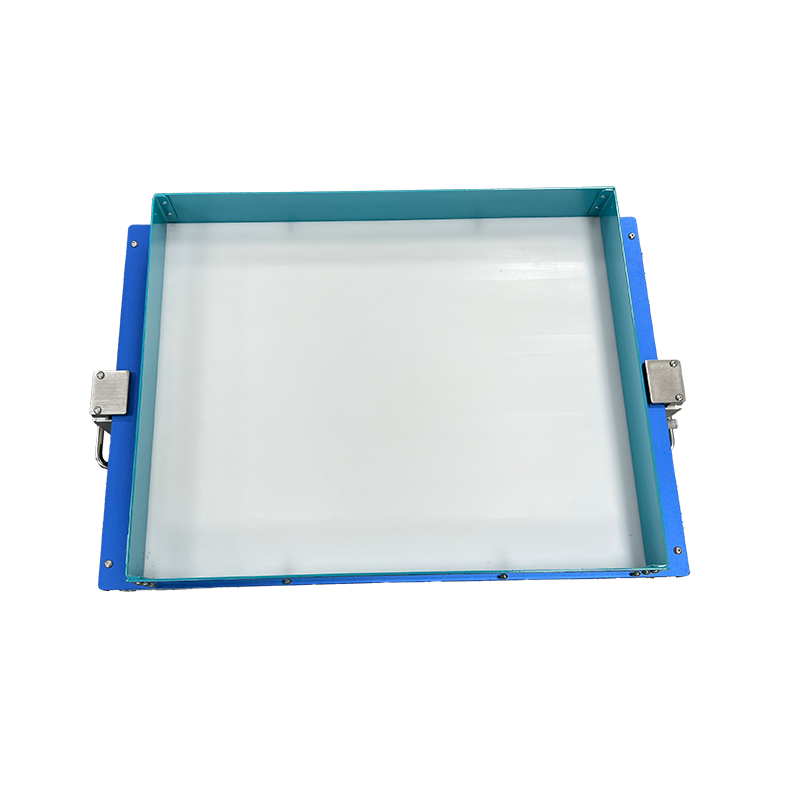

Our Flexible Feeding Platform is an advanced, fully adaptable feeding solution designed to work seamlessly with vision inspection systems,making it ideal for industries requiring high precision, rapid changeovers, and multi-variety component handling.

Whether you are in electronics, medical devices, hardware, automotive, or consumer goods, this platform helps you achieve efficient, reliable, and intelligent automation.

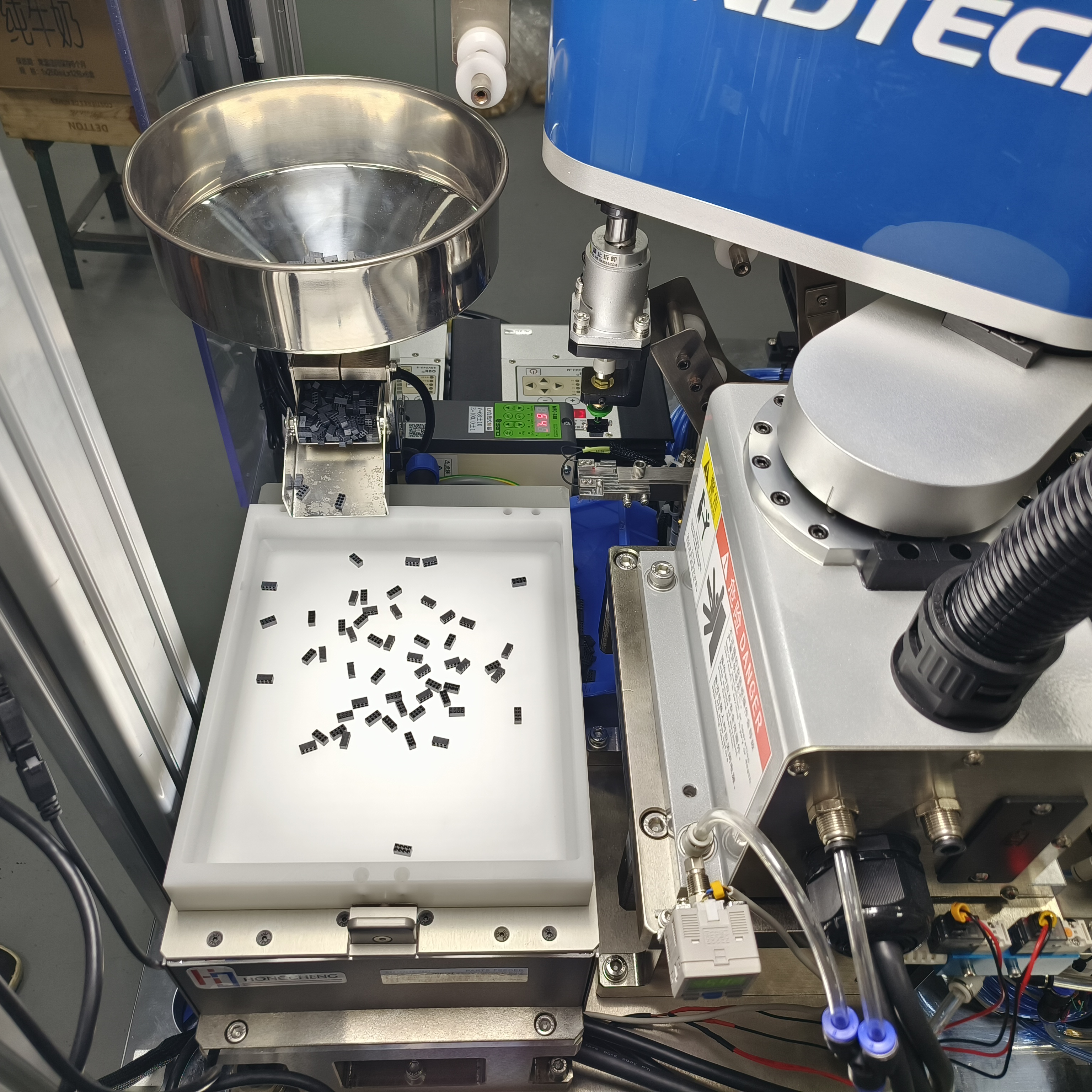

1.Compatible with Vision Systems

The platform can be perfectly integrated with various industrial cameras and AI vision software.

Supports accurate part identification

Enables multi-directional positioning

Ensures precise pick-and-place operations with robots

This greatly improves accuracy while reducing manual intervention.

2.Handles Multiple Materials and Shapes

Unlike traditional vibration bowl feeders, the flexible platform adapts to different sizes, shapes, and materials without mechanical adjustment.

Ideal for frequent product changes

Supports small and lightweight components

Perfect for customized or high-mix production lines

3.Fast Changeover for Multi-SKU Production

No need to replace tooling.Through software adjustment, a single platform can feed several types of components, significantly reducing downtime and increasing production flexibility.

4.High Stability & Continuous Output

Equipped with an optimized vibration algorithm and durable structure, it provides:

Stable material flow

Consistent feeding

Low noise & long service life

Ensuring reliable performance even in long-term, 24/7 operations.

5.Compact Design with Easy Integration

The modular design allows quick integration with:

Robots

Conveyors

Vision systems

Sorting or packaging equipment

It is suitable for both new lines and upgrades of existing automation equipment.

Electronics components

Hardware parts

Plastic accessories

Medical device parts

Precision mechanical components

Small consumer goods

Wherever flexibility and accuracy are required, this platform delivers.

20+ years of expertise in vibration feeding solutions

Strong R&D support with customized design available

Reliable performance proven across global customer applications

Suitable for complex, high-mix automated production lines

If you need a high-flexibility, vision-compatible feeding solution, our engineering team can provide a complete proposal based on your materials and production requirements.