The following is our series of articles, if you are interested, you can click to view:

In the previous article, we introduced the methods of vibratory bowl feeder to deal with wet materials, including designing special materials, designing the machine to be anti-stick, and installing a heating system for the machine. This article will continue to explain the methods of vibratory bowl feeder to deal with wet materials.

The vibration parameter adjustment of the vibratory bowl feeders for automated assembly can optimize the flow state of wet materials. For fine particulate materials with high water content, high-frequency vibration is used to make the material bounce slightly on the surface of the tank body and reduce adhesion. For wet materials that are agglomerated, the frequency is reduced and the amplitude is increased, and the agglomeration is dispersed by a strong impact force, reducing the accumulation of materials. The adjustment of the amplitude can be matched with the change of the viscosity of the material. If the sensor detects that the flow of the material slows down, the amplitude will be increased and a stronger vibration force will be used to push the material forward. Some equipment will install frequency-conversion speed-regulating motors, which can automatically switch the vibration mode according to the humidity of the material to ensure that materials of different moisture levels can maintain a stable flow state on the vibratory bowl feeder.

The tilt angle of the vibratory bowl feeders for automated assembly can be adjusted according to the material characteristics. For wet materials with medium viscosity, set the tilt angle of the tank to about 20 degrees to ensure that the material will slide by gravity and will not be too fast. When handling very viscous materials, the angle can be increased to 25-30 degrees, and the vibration can be turned on to cooperate with the work. The operator can adjust at any time according to changes in the humidity of the material on site.

Anti-blocking devices can be installed at the outlet of the vibratory bowl feeders for automated assembly trough. Some anti-blocking devices are also equipped with infrared sensors. When the material accumulates at the outlet with a thickness of more than 5 cm, an alarm will be triggered immediately and the cleaning procedure will be started to ensure the smooth operation of the outlet.

If customers have needs, we can provide customized services. From material characteristics, discharge requirements, and installation space restrictions, we will understand in detail to ensure that the manufactured vibratory bowl feeders for automated assembly meet customer needs.

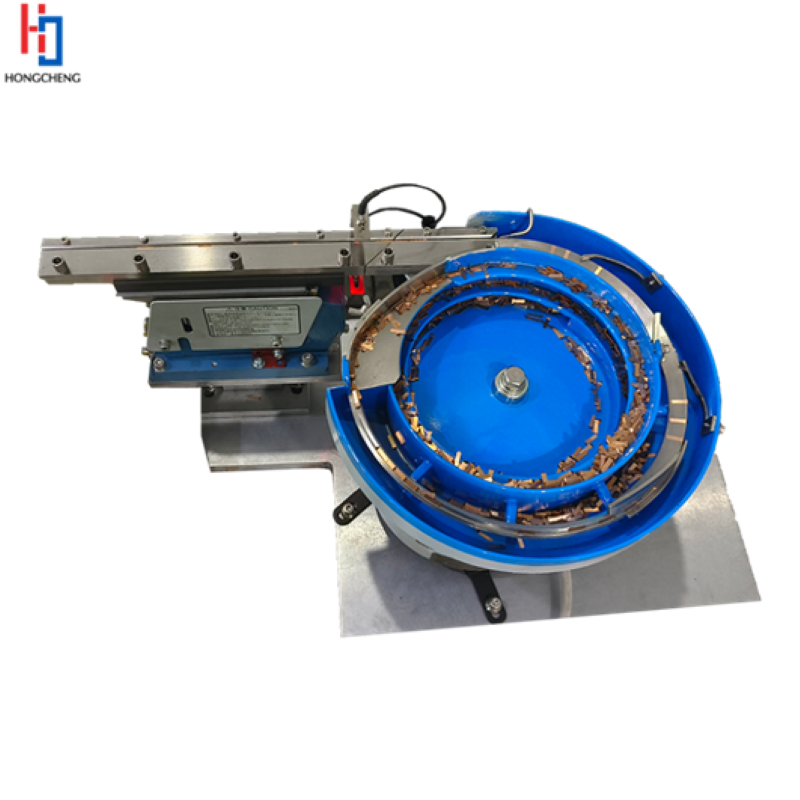

Shenzhen Hongcheng Automation Equipment Co., Ltd. focuses on the innovation and manufacturing of vibratory bowl feeders for automated assembly and automated conveying systems. We have advanced equipment and excellent quality to design products that satisfy customers. Our products are widely used in many industries such as electronics, medical care, food, hardware, etc. We also have a perfect after-sales service system and excellent after-sales service personnel. If you have any questions, please feel free to contact us, and we will continue to explain how the vibratory bowl feeder handles wet materials. If you are interested, you can continue to pay attention to our website.