Vibratory Feeders: The Indispensable Backbone of Modern Automated Production Lines

In the realm of industrial automation, the pursuit of efficiency, consistency, and uptime is paramount. At the core of this pursuit lies a deceptively simple yet critically important component: the vibratory feeder. Far more than a basic conveyance device, a vibratory feeder is a sophisticated and precision-engineered uptream feeding system. It serves as the vital initial stage in the production line, acting as the essential interface between bulk material storage and all subsequent high-speed, precision-driven processes.

Positioned at the very beginning of the value stream, its primary role is to sort,orient,and singulate randomly stored components. It transforms chaos into order, reliably delivering a steady flow of perfectly positioned parts to downstream equipment such as robotic arms for assembly, precision placement modules, vision inspection systems, and packaging machinery. The performance of this upstream process directly dictates the rhythm, stability, and overall productivity of the entire production line, making it not just an accessory, but the foundational backbone of reliable automation.

The Science of Precise Movement: How Vibratory Feeders Operate

The operational principle of a vibratory feeder is elegant in its simplicity yet powerful in its application. The system primarily consists of a drive unit, a spring system, and a conveying track or bowl. The drive unit—which can be electromagnetic or electromechanical—generates controlled, high-frequency vibrations. These vibrations are transmitted through the spring assembly to the conveying surface, creating a repeating cycle of micro-lifts and forward throws.

This action causes parts to move in a series of small, controlled hops along the track. The direction and character of this movement are precisely engineered. By carefully adjusting the vibration amplitude (the "power" of the vibration) and, in some systems, the frequency, operators can achieve exact control over the feed rate—from a complete halt to a rapid, steady stream. This level of control ensures not only consistent volume but also gentle handling of even the most delicate components, minimizing part-on-part impact, surface damage, and deformation.

From Chaos to Order: The Critical Role in Automation Ecosystems

The primary and most valued function of a vibratory feeder within an automated line is its ability to transform disordered bulk into organized, singular flow. This process involves two key stages:

Bulk to Oriented Flow: A vibratory bowl feeder is the most common embodiment of this. Parts are loaded in bulk into the center of the bowl. As the bowl vibrates, parts travel up the helical track that winds around the inner wall. Integrated tooling, tracks, wipers, and selectors—custom-designed for the specific part geometry—actively interact with the parts. Incorrectly oriented parts are gently rejected back into the bowl's reservoir, while only parts in the desired orientation are allowed to pass. This self-regulating process results in a continuous, single-file stream of perfectly oriented components exiting the bowl's output track.

Synchronized Delivery to Downstream Processes: This organized output is precisely timed to feed subsequent automation. Whether the destination is a robotic gripper waiting to assemble, a test probe for electrical verification, a camera station for dimensional inspection, or a blister pack for final packaging, the feeder ensures parts are presented at the right place, at the right time, and in the right orientation. This synchronization eliminates bottlenecks, prevents downstream equipment from idling ("part starvation"), and avoids the costly jams and misfeeds caused by malformed or misaligned parts.

Driving Operational Excellence: Key Benefits and Strategic Advantages

Implementing a well-engineered vibratory feeding system delivers tangible, bottom-line benefits that directly impact manufacturing key performance indicators :

Maximized Line Uptime & OEE: Reliable, jam-resistant feeding is the first defense against unplanned downtime. A stable feeder ensures that high-value downstream assets like robots and CNC machines operate at their designed cycle times, directly improving Overall Equipment Effectiveness.

Enhanced Product Quality and Yield: Consistent part orientation and spacing are critical for error-proof assembly and accurate inspection. This precision reduces assembly defects, misalignments, and false rejection rates, leading to higher first-pass yield and superior final product quality.

Reduced Operational Costs: The robust, low-maintenance mechanical design of vibratory feeders minimizes service requirements and associated labor costs. Furthermore, by drastically reducing part damage, scrappage, and waste due to feeding errors, material costs are better controlled.

Unmatched Flexibility and Scalability: Modern feeders are designed for the era of high-mix, low-volume production. Features like quick-change bowls, modular and adjustable track tooling, and digitally controlled drives allow for rapid changeover between different part numbers. This agility supports flexible manufacturing strategies and future-proofs the production line.

Seamless Integration with Industry 4.0: Today's advanced vibratory feeders are intelligent system components. They can be equipped with sensors to monitor feed rate, bowl level, and drive health.

Selecting the Right Partner: A Decision That Impacts Your Entire Line

Choosing a vibratory feeder should never be an afterthought. It is a strategic investment in line stability. The most effective systems are not merely "purchased" but are "engineered" through close collaboration between the manufacturer and the end-user. Key considerations include:

Part Characteristics: Size, weight, geometry, material, and fragility.

Rate Requirements: Required parts per minute (PPM) under sustained operation.

Line Environment: Noise control specifications.

Integration Needs: Control interface (analog/digital I/O, fieldbus), physical footprint, and connectivity with existing automation.

A properly specified and custom-tuned vibratory feeder does more than just move parts; it synchronizes, stabilizes, and supercharges the entire production sequence. It transforms a collection of individual machines into a cohesive, efficient, and truly automated production system.

About Shenzhen Hongcheng Automation Equipment Co., Ltd.

Shenzhen Hongcheng Automation Equipment Co., Ltd. stands as a dedicated specialist in the design, engineering, and manufacturing of high-performance vibratory feeding solutions. We focus on delivering more than just hardware; we provide complete, automation-ready feeding systems that solve real-world production challenges.

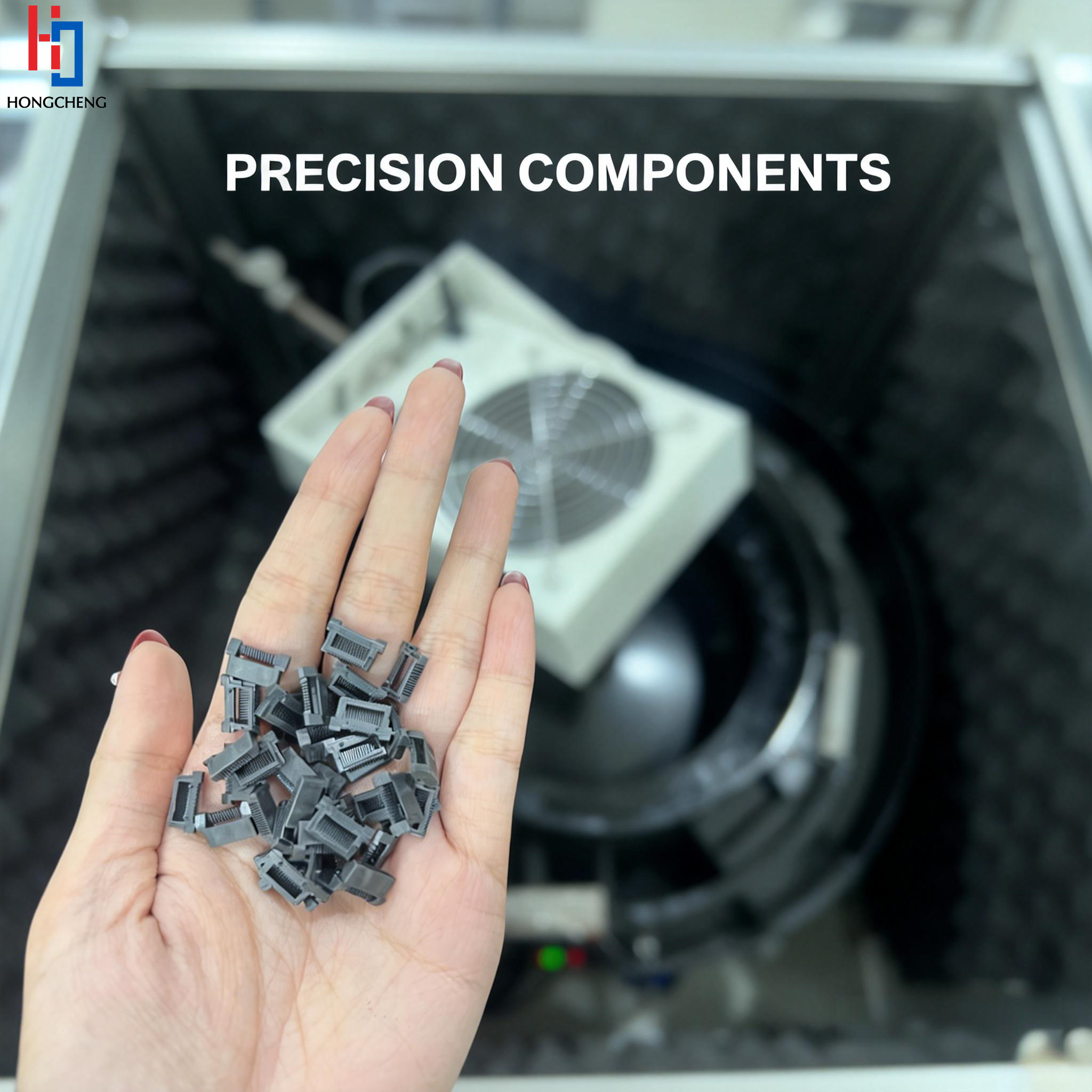

Our expertise covers the entire spectrum—from standard electromagnetic and electromechanical drive units to fully custom-designed vibratory bowls with complex tooling for intricate part orientation. We serve a diverse range of demanding industries including precision electronics, automotive hardware, fastener assembly, pharmaceutical and medical device manufacturing, and consumer goods packaging.

At Hongcheng, our process begins with understanding your unique application. We combine proven engineering principles with innovative customization to develop feeders that offer exceptional reliability, gentle part handling, and easy integration. Our goal is to become your trusted partner in automation, ensuring your production lines achieve their highest potential in throughput, quality, and reliability. Let us engineer the foundation for your success.