Aluminum bowl feeder vibrating is actually easier to maintain than plastic ones. Many people's first reaction is that plastic ones are not easy to rust, so is it easier to maintain? In fact, this is not entirely true. Aluminum alloy itself has very good corrosion resistance, higher strength, more stable structure, and is not easy to deform or wear due to long-term operation. This means that bowl feeder vibrating is more durable during use, and daily maintenance work is simpler. You only need to regularly clean the dust and impurities on the bowl body and keep the inside clean and dry to run stably for a long time.

Although Bowl Feeder Vibrating looks light, it is easy to have scratches, breaks, deformations and other problems in production lines with high intensity or high frequency operation, especially when the material is heavy or the use environment is more complex. The aluminum Bowl Feeder Vibrating is more "durable" in this regard. It is very stable even if it runs continuously for a long time, reducing the trouble and downtime risks caused by frequent replacement of parts. In addition, aluminum Vibratory Bowl Feeder also supports polishing and repair, and it is very convenient to deal with small problems.

Our factory has many years of experience in the production of aluminum Vibratory Bowl Feeder, with complete equipment and mature technology. The most important thing is that we are very good at optimizing the structure according to the customer's usage scenarios. For example, which positions are prone to dust accumulation and which parts need to be strengthened against wear, we can take them into consideration in advance during the design, so that the entire product will be smoother and less problematic in later use. In other words, the aluminum Vibratory Bowl Feeder we produce not only requires less maintenance, but is also easy to do.

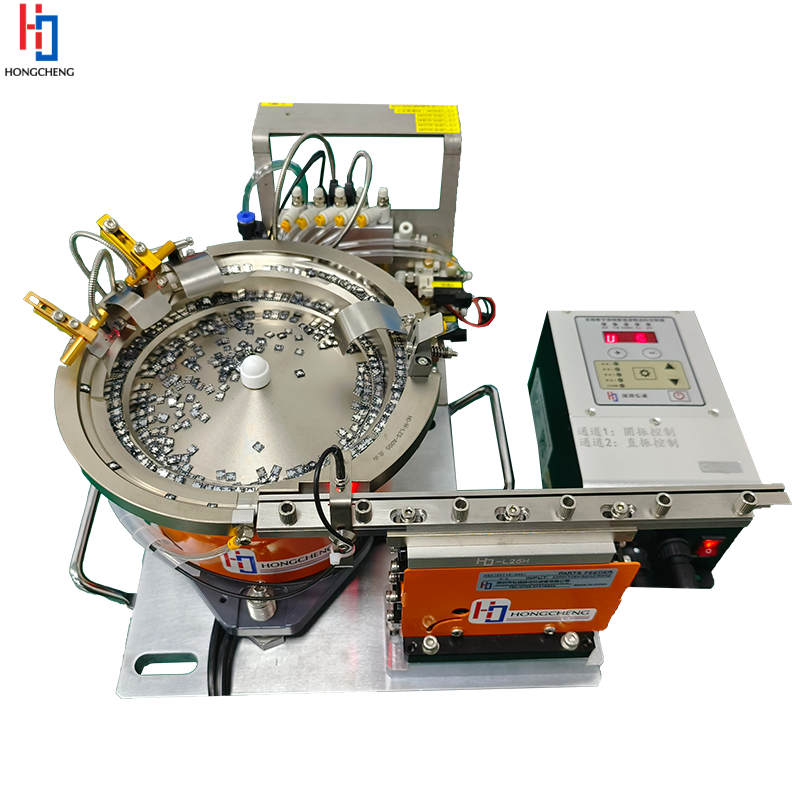

The HONGCHENG factory is equipped with high-precision five-axis CNC machining equipment. The bowl body structure processed is highly accurate, with strict tolerance control, and it is not easy to deviate after long-term use. Our bowl body is anodized, which not only looks beautiful, but also has strong corrosion resistance. It is not afraid of oil, water, or some chemical cleaning agents, and the cleaning work is very convenient. As long as you wipe it every day and check if there is any stuck material, you can keep it in good condition, and even the maintenance manual seems "not that important".

Our design team is also a highlight. We communicate very smoothly with customers. Many customers only provide material samples and installation space information, and we can quickly design a suitable bowl structure. Moreover, the whole process of drawing review and proofing test can be coordinated with the customer's rhythm without delaying the progress. We can also optimize and upgrade the old bowl provided by the customer to make the user experience even better.

In addition, we support small batch trial production and on-site testing services. If customers are worried about the effect, we welcome them to come to the door for testing with materials; if customers are not clear about how to do the later maintenance, we can provide video demonstrations or detailed operation instructions. We hope that every customer can feel at ease to produce after using our aluminum bowl feeder without worrying about small problems.

If you are currently purchasing Vibratory Bowl Feeder, you may wish to consider our aluminum Vibratory Bowl Feeder. Lightweight, durable, and easy to maintain, customers who have used it say that the stability of Vibratory Bowl Feeder is particularly good. Welcome to leave a message, call or video communication, maybe we have a design that is tailor-made for you.