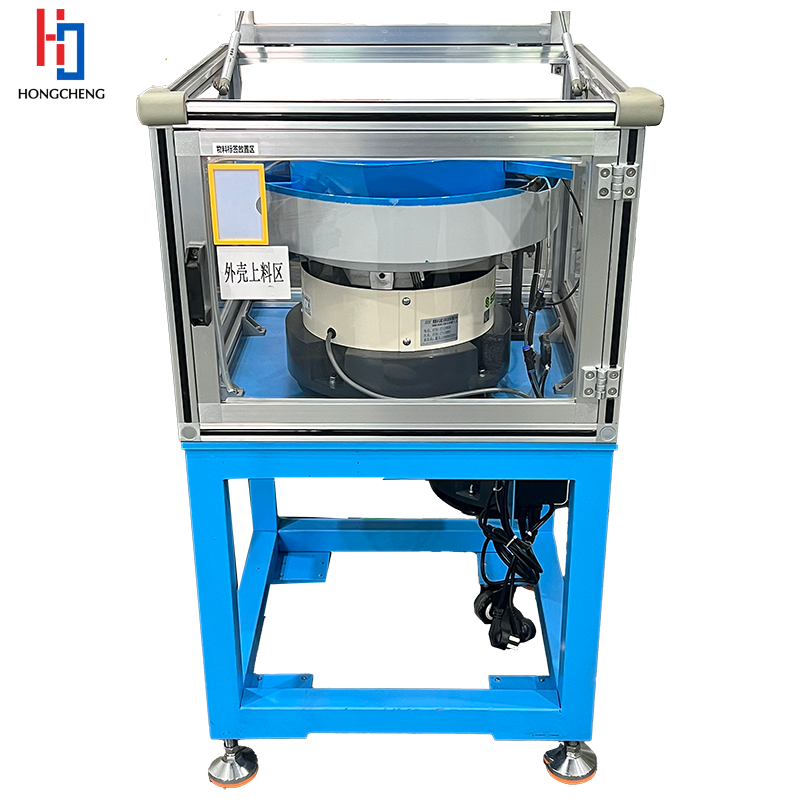

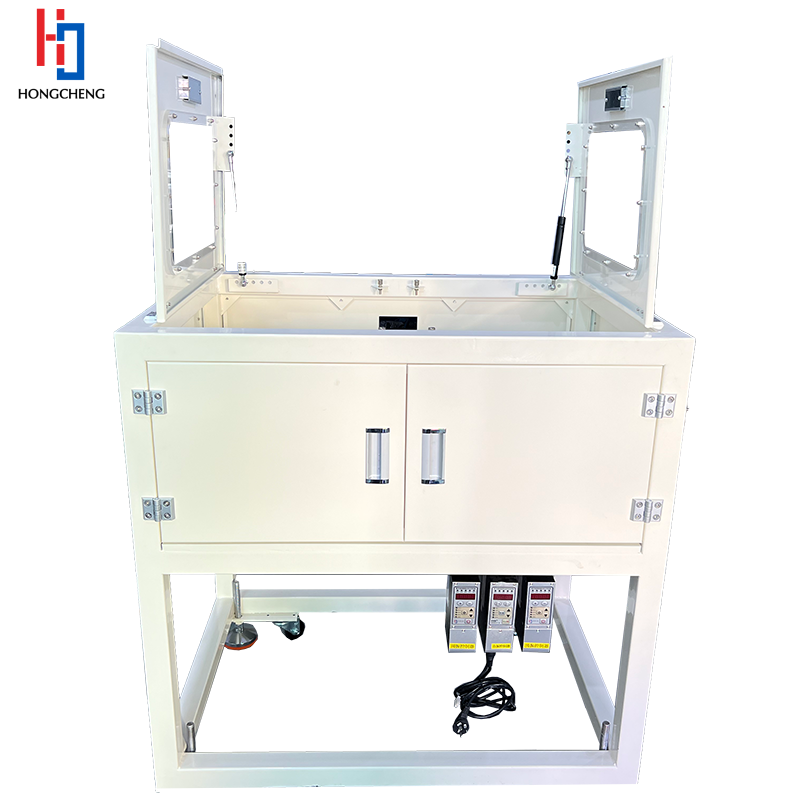

Introduction of sound enclosure for vibratory bowl feeders:

Vibration plate sound insulation cover can seal the vibration plate as a whole and shield the noise during operation. Vibration plate soundproof cover will not affect the normal operation of the vibration plate. Vibratory bowl feeder soundproof cover

Can reduce the noise caused by the collision between workpieces, minimize the noise, and improve the working environment.

Advantages of vibration plate sound insulation cover:

1.Vibration plate soundproof cover can reduce noise, improve the alertness and reaction speed of workers, and reduce the risk of misoperation.

2.Vibratory bowl feeder soundproof cover can indirectly protect the mechanical parts of the vibration plate, reduce the wear on the vibration plate caused by vibration transmission, and extend the service life of the vibration plate.

3.Sound enclosure for vibratory bowl feeders is made of durable materials, which can reduce maintenance costs.

Installation steps of vibratory bowl feeder soundproof cover:

When we install the vibratory bowl feeder soundproof cover, we must first fix the sound insulation cover stably around the vibration plate, and then connect the power supply and control line of the vibration plate, so as not to affect the normal operation of the vibration plate. Then debug the vibration plate and check whether the sound insulation cover affects the vibration frequency of the vibration plate. After the installation of sound enclosure for vibratory bowl feeders, conduct a final inspection to check the sealing and sound insulation effect of the sound insulation cover. Check the operation status of the vibration plate sound insulation cover regularly, and perform maintenance and replacement when necessary.

Application of vibration plate soundproof cover:

In electronic manufacturing plants, vibration plates are generally used to transport electronic components such as resistors and capacitors. The vibration plate will generate high noise during operation, which affects the hearing health and working environment of employees. Vibratory bowl feeder soundproof cover can effectively isolate noise and protect workers. Sound enclosure for vibratory bowl feeders can not only evenly distribute and transport materials in food production lines, but also prevent the spread of dust and pollution to ensure food safety. Vibration plate sound insulation cover can prevent the influence of noise on the quality of medicines and provide a quiet production environment.

About us:

Shenzhen Hongcheng Automation Equipment Co., Ltd. is a company specializing in automatic feeding systems (vibration plates) and non-standard automation equipment, integrating R&D, production, sales and service. The company's products cover automatic feeding vibration plates, automatic feeding bins, linear feeders, electronic control systems and vibration platforms, etc., which are widely used in light industrial machinery, standard parts processing, connector assembly and bearing manufacturing and other industries to meet the automation needs of different fields.