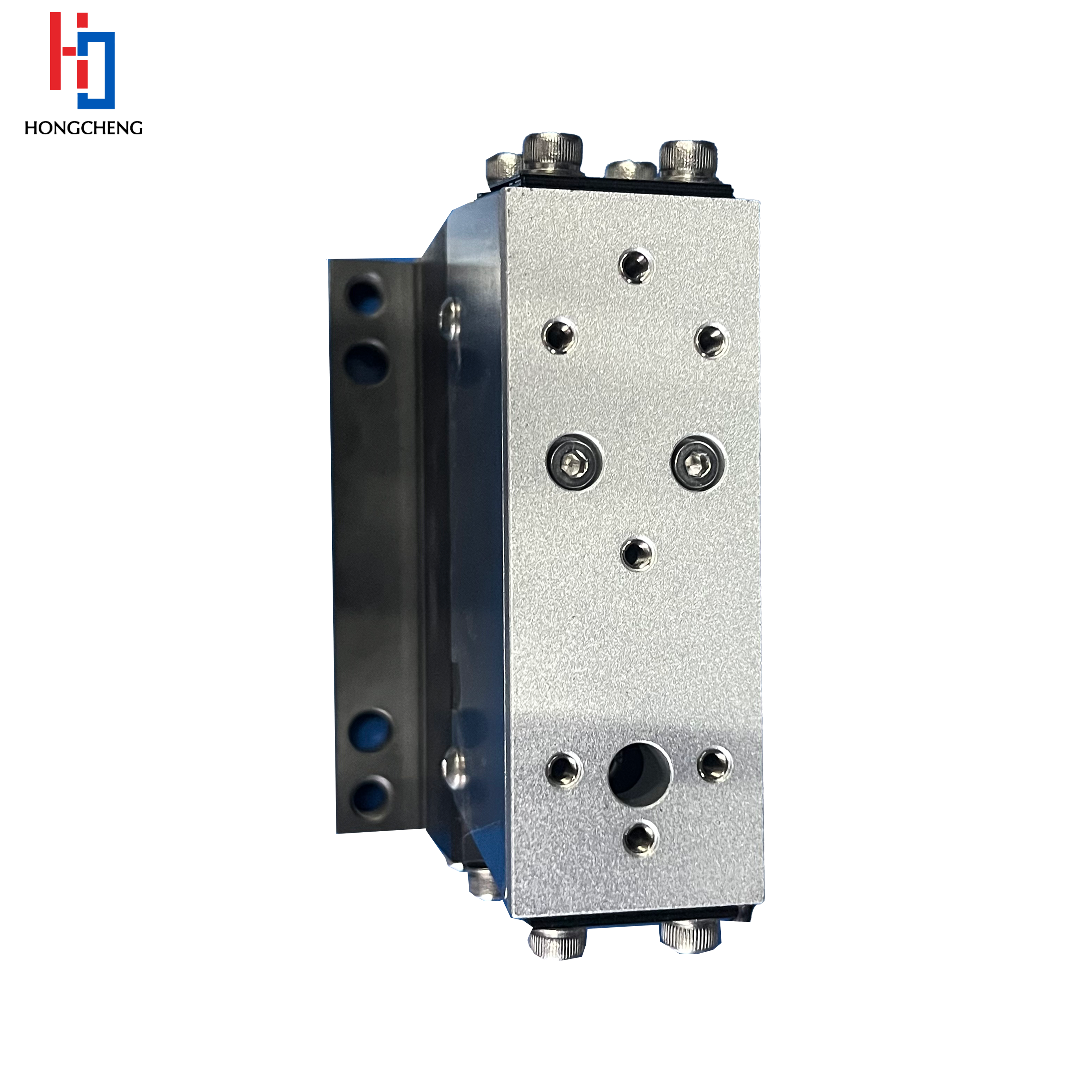

Introduction of basic linear vibratory feeder:

220v automatic feeding machine linear feeder can automatically and orderly arrange disordered workpieces and transport them to the next process. Direct vibration feeder vibrating plate controller is mainly composed of hopper, chassis, controller and linear feeder. Basic linear vibratory feeder is widely used in battery, hardware, electronics, medicine, food and other industries.

Advantages of basic linear vibratory feeder:

1. The linear feeding system of 220v automatic feeding machine linear feeder runs smoothly, with low energy consumption, energy saving and environmental protection.

2. Direct vibration feeder vibrating plate controller can control the conveying speed and direction of materials by adjusting the vibration frequency and parameters,

3. Basic linear vibratory feeder adopts mechanical automation to reduce manual operation and improve production safety.

How to choose 220v automatic feeding machine linear feeder?

When choosing direct vibration feeder vibrating plate controller, you must first determine the specific characteristics of the material. Metal parts have greater friction during vibration, so a feeder with stronger vibration force is required. Plastic parts are lighter and easily interfered by static electricity, so the surface of the basic linear vibratory feeder May require special treatment. It also needs to be selected according to the installation environment, maintenance cost, and production needs.

FAQ:

1. What is the working principle of the 220v automatic feeding machine linear feeder?

It uses electromagnetic vibration or mechanical vibration to move the material along the set track to achieve continuous feeding.

2. Does the direct vibration feeder vibrating plate controller need to be cleaned regularly?

Yes, clean the track and the inside of the vibration plate regularly to prevent dust and debris from affecting the feeding effect

3. What materials can the basic linear vibratory feeder convey?

Suitable for the conveying of small materials such as electronic components, hardware accessories, plastic parts, and medical supplies.

4. How to reduce the wear of the basic linear vibratory feeder?

Choose the appropriate amplitude, avoid overload operation, and replace vulnerable parts regularly.

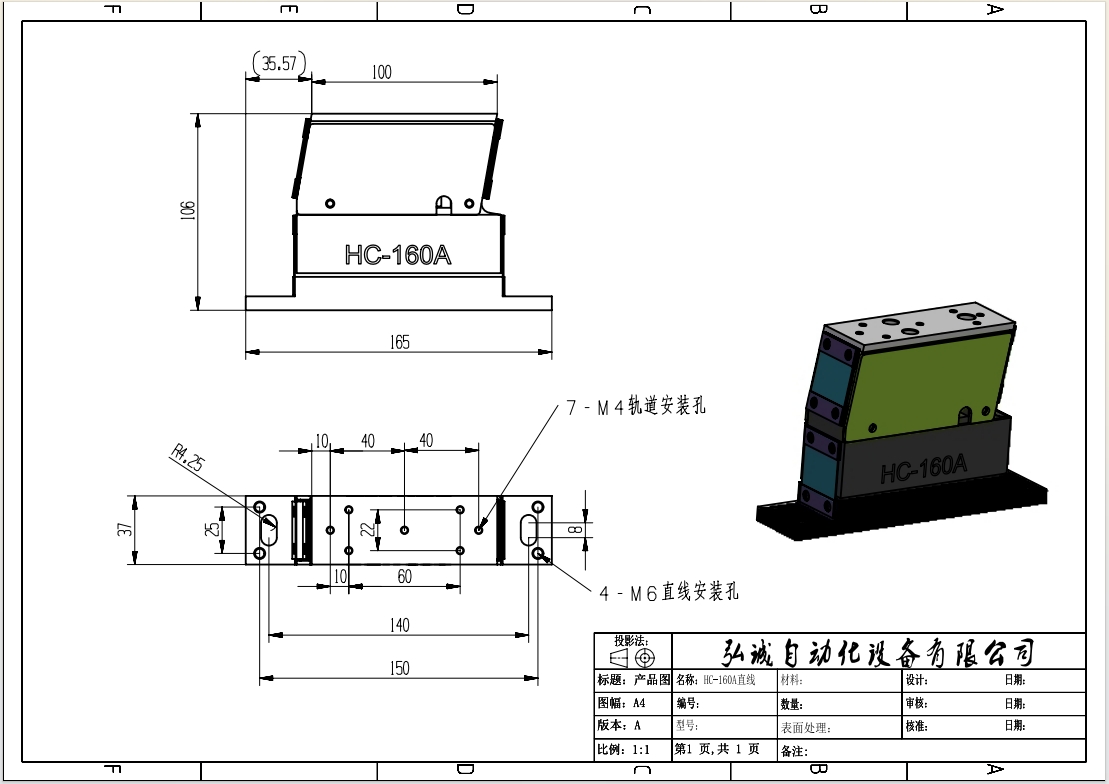

About us:

Shenzhen Hongcheng Automation Equipment Co., Ltd. is a company specializing in providing automatic feeding systems (vibration plates) and non-standard automation equipment, integrating R&D, sales and after-sales service. The company's products include automatic feeding vibration plates, automatic feeding bins, linear feeders, electronic control systems and vibration platforms, which are widely used in light industrial machinery, standard parts production, connector manufacturing and bearing industries.