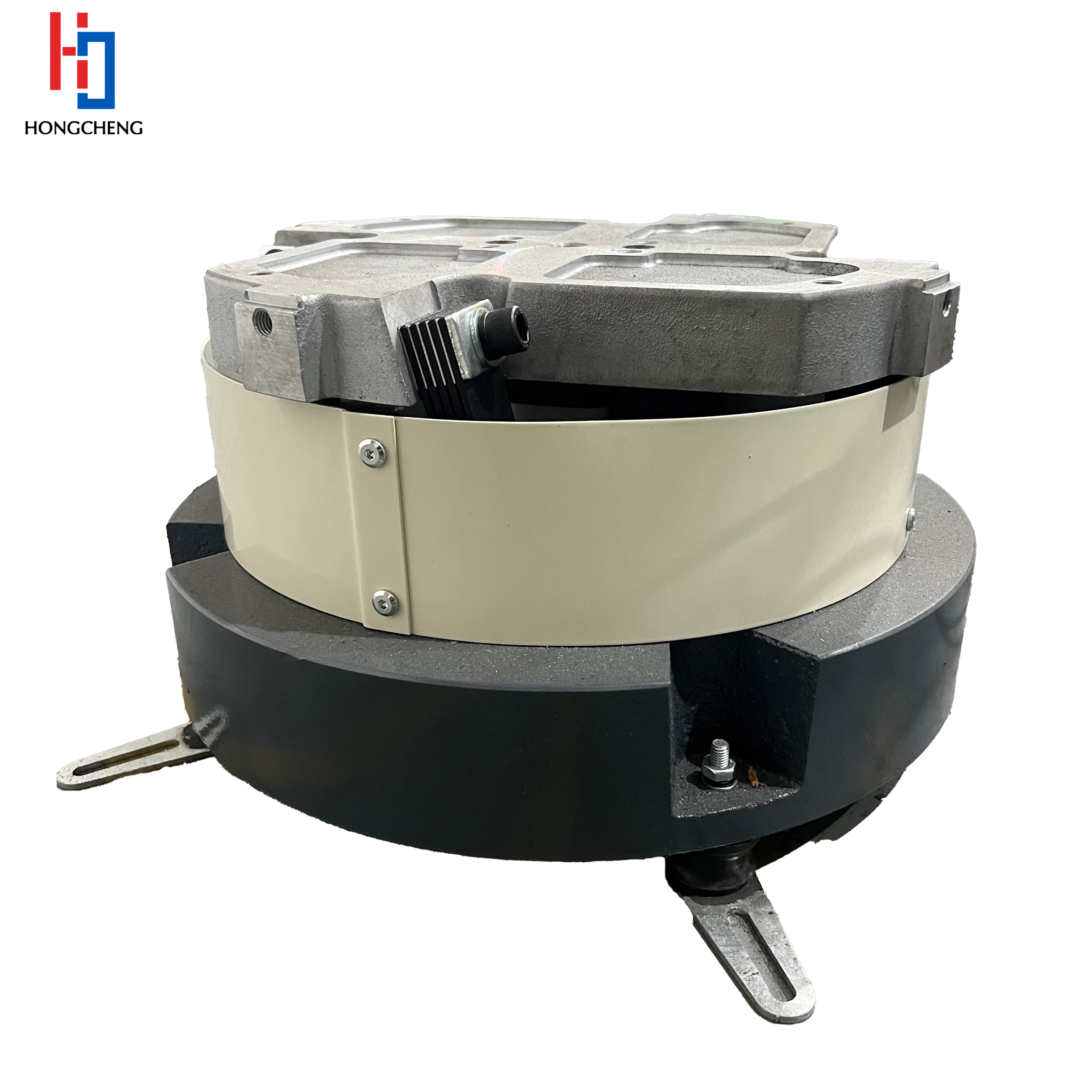

Product introduction:

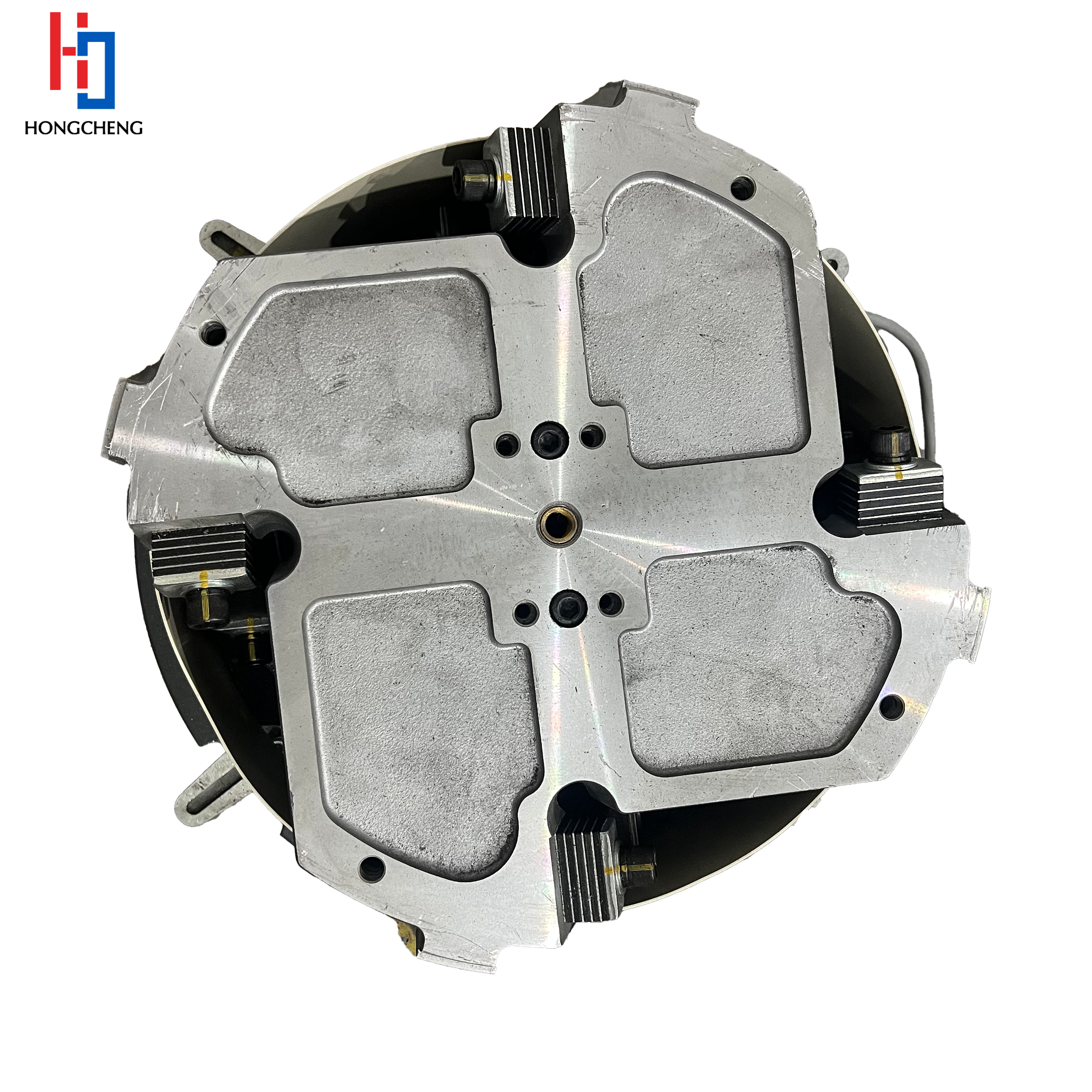

160T vibration feeder base is a device developed for vibratory feeding system, which allows materials to be smoothly conveyed according to the set trajectory, ensuring the stability and accuracy of the feeding process. 160T vibration feeder base is equipped with high-quality accessories, which can extend the service life of the vibration plate and reduce maintenance costs. Therefore, small linear vibration feeder vibrating base can be used for different types of materials such as metal, plastic, electronic components, etc.

Product advantages:

1.220v vibration plate base for vibratory feeder can reduce the impact of the vibration plate on surrounding equipment and structures, and reduce noise pollution.

2.160T vibration feeder base can ensure the support and stability of the vibration plate, and it will not shake or tilt during work.

3.Compared with similar products, 160T vibration feeder base has lower energy consumption and can reduce costs.

Application of 220v vibration plate base for vibratory feeder:

The 160T vibration feeder base runs stably during operation and can be used for precise feeding of electronic components and semiconductors. Therefore, the small linear vibration feeder vibrating base can also be used to transport medical device components. The small linear vibration feeder vibrating base can automatically arrange hardware such as screws, springs, nuts, etc., and smoothly transport them to the next process. Small food packaging and automated sorting require the selection of a vibration plate base that meets food safety standards. Our 220v vibration plate base for vibratory feeder uses high-quality materials and meets the use standards of food products.

Working principle of 160T vibration feeder base:

The small linear vibration feeder vibrating base uses a vibrating electromagnetic drive system to transport materials along a set trajectory. By adjusting the amplitude, frequency and direction of the 220v vibration plate base for vibratory feeder, the material moves forward at the set speed and angle, and the sensor detects the feeding situation to achieve automatic adjustment.

Maintenance and care of 160T vibration feeder base:

In our daily use of small linear vibration feeder vibrating base, we should clean the surface of the vibration plate regularly to avoid dust accumulation and affect the use effect. Check the fixing parts of the 220v vibration plate base for vibratory feeder to see if the screws, brackets and other parts are loose, and then use lubricants appropriately to reduce the friction between the base and the vibration plate and extend the service life. It is also necessary to use it according to the instructions of the 160T vibration feeder base, and do not avoid overload operation.

About us:

Shenzhen Hongcheng Automation Equipment Co., Ltd. focuses on the research and development, sales and service of automatic feeding systems (vibration plates) and non-standard automation equipment.The company mainly provides automatic feeding vibration plates, automatic feeding bins, linear feeders, electronic control systems, vibration platforms and other products, which are widely used in light industrial machinery, standard parts production, connector manufacturing, bearing processing and other industries.