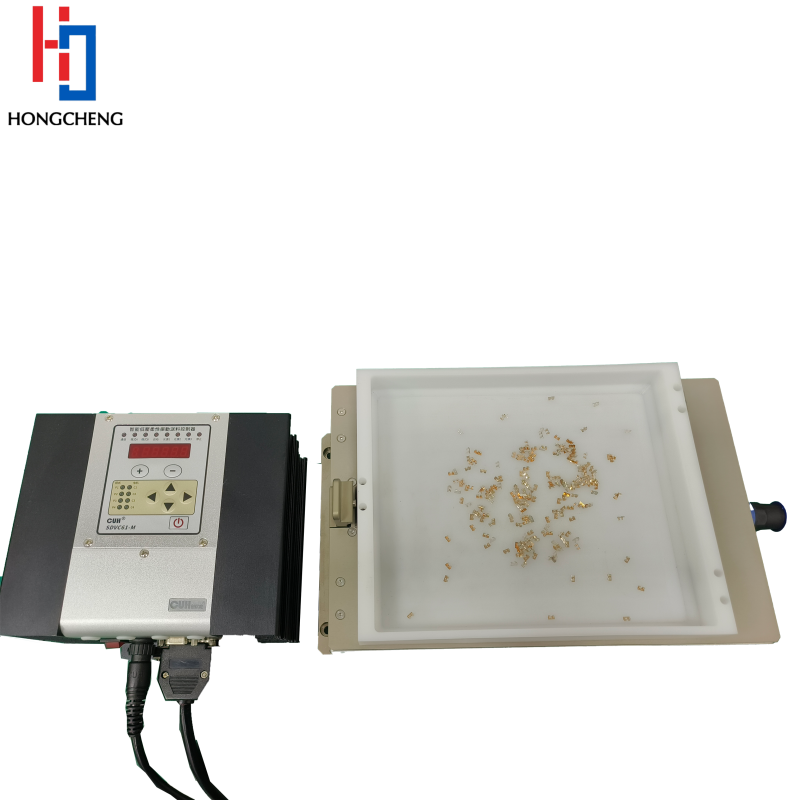

Description of flexible vibrating feeder platform:

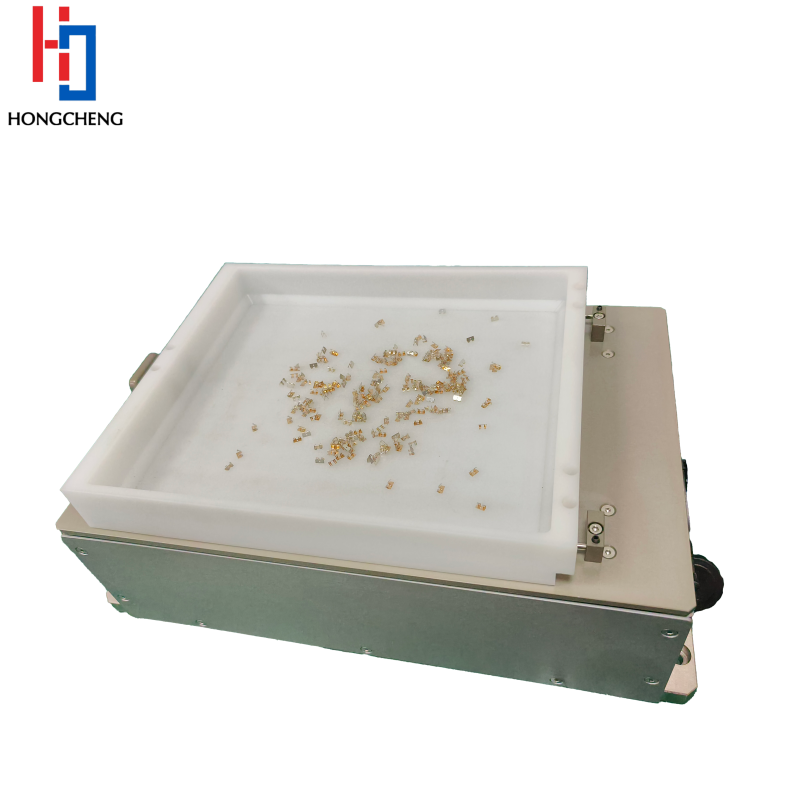

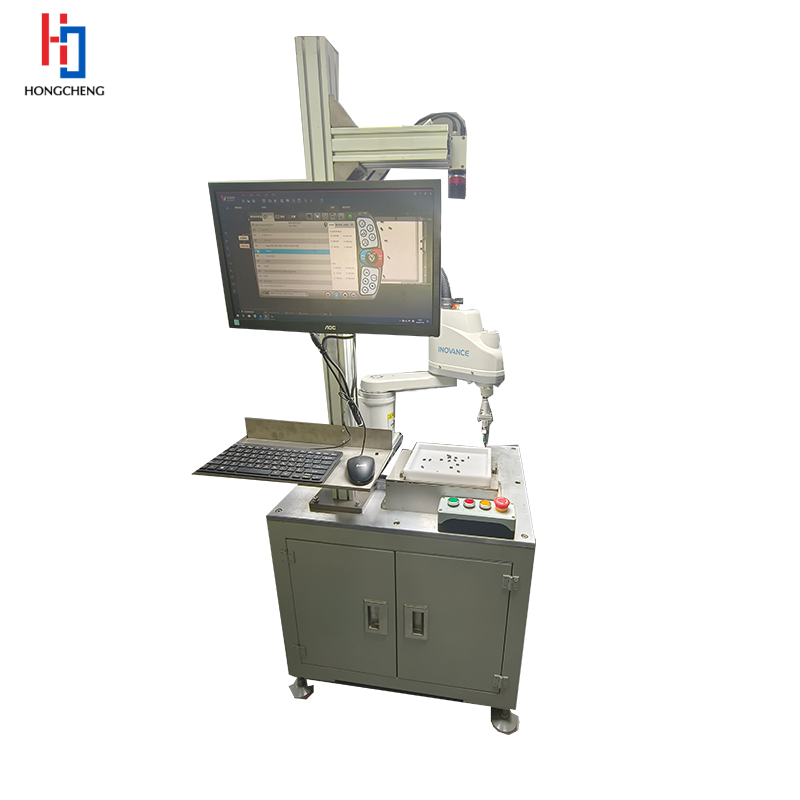

Flexible vibrating feeder platform is a feeding equipment specially designed for automated production lines. It can be used to convey various small parts, electronic components, medical equipment accessories and other materials. Compared with traditional rigid vibrating plates, vibrating feeding platform with blue backlight conforms to the production mode of multiple varieties, small batches and fast switching, which improves the flexibility and adaptability of the automation industry.

Advantages of flexible vibrating feeder platform:

1. Flexible vibrating feeder platform has a compact structure and small footprint, which is suitable for various production environments.

2. The maintenance cost of vibrating feeding platform with blue backlight is low, and its service life is long compared with similar products.

3. Fully automatic flexible vibrating plate is environmentally friendly and energy-saving, which can reduce energy consumption.

Product parameters:

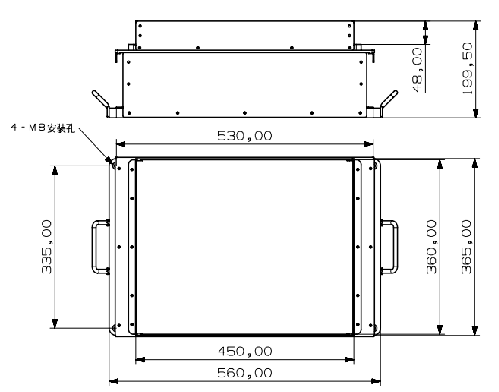

The size of vibrating feeding platform with blue backlight is 560*365*199.5 (mm), and its inner size of the tray is 450*360 (mm). The height of the tray sidewall is standard 48mm and 55mm, and we can accept customized services. The weight of the fully automatic flexible vibrating plate is 34kg, the working power supply is dc24v/8a, the vibration frequency is exactly the same as the working frequency of the same type of vibration plate, and the working frequency of different materials is also exactly the same. The no-load noise of the flexible vibrating feeder platform is ≤75 decibels, the maximum load-bearing capacity is 3kg, the size range of the flippable material is 10-40mm fine parts, and the maximum weight of the flippable material is ≤80g. The single action beat of the vibrating feeding platform with blue backlight is between 150-300ms, and it adopts vertical vibration dispersion, gathering, and one-way movement around the action mode. It has a built-in white backlight and the brightness can be adjusted. In addition, the control driver board of the fully automatic flexible vibrating plate is built-in, circuit isolated, input and output npn, multi-waveform control, and uses tcp/ip communication and io control.

FAQ:

1. What industries are the flexible vibrating feeder platform suitable for?

It is widely used in electronic manufacturing, automotive parts, medical equipment, semiconductors, precision manufacturing and other industries.

2. What is the working principle of vibrating feeding platform with blue backlight?

It mainly distributes the parts evenly on the feeding table through the principle of vibration to achieve accurate grasping and feeding.

3. What is the difference between fully automatic flexible vibrating plate and traditional vibrating plate?

Traditional vibrating plates are generally designed for single parts, while flexible feeding tables can adapt to parts of different shapes and specifications, and the debugging time is short.

About us:

Shenzhen Hongcheng Automation Equipment Co., Ltd. focuses on the research and development, production and sales of non-standard automation equipment and automatic feeding systems (vibrating plates). We have advanced production technology, strict quality control system, and fine production process to ensure stable product quality. The main products include automatic feeding vibrating plates, automatic feeding bins, precision aluminum plates, flexible platforms, centrifugal equipment, etc., which are widely used in oil-containing bearings, nozzles, buttons, batteries, medical devices and other industries.