Introduction to automatic flexible vibrating plate:

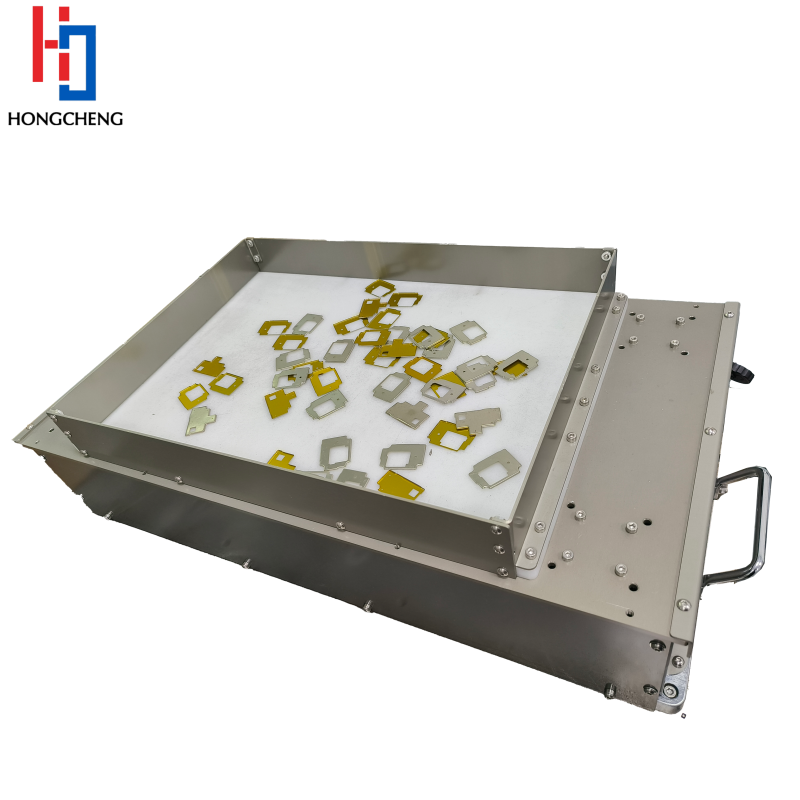

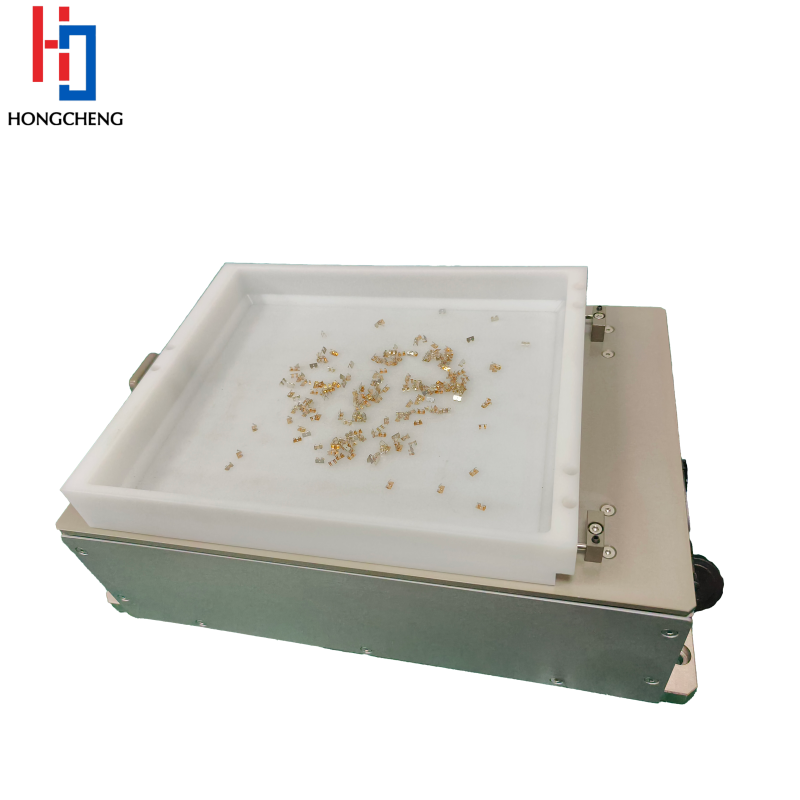

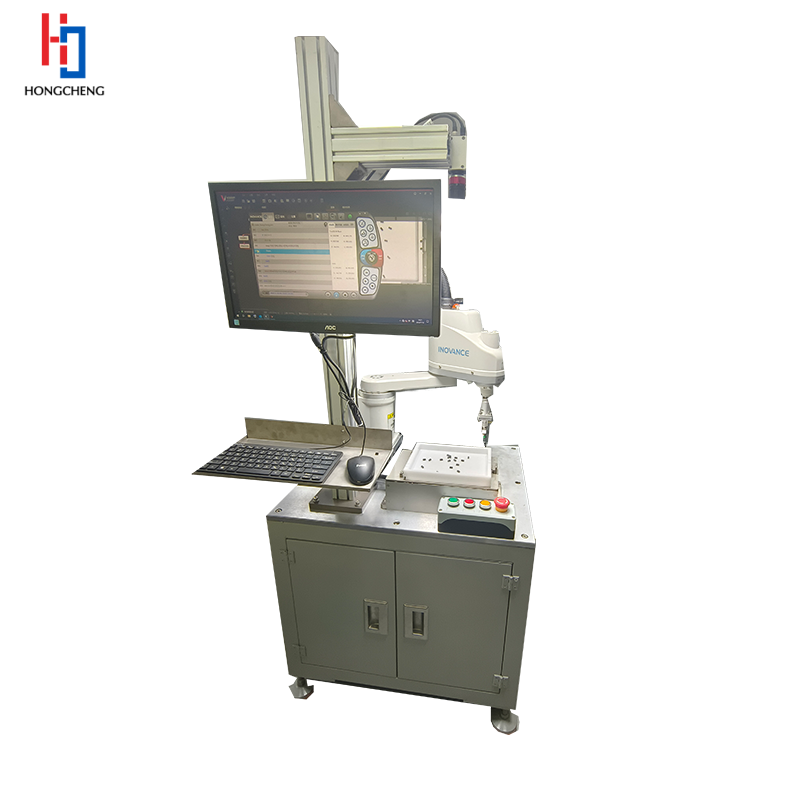

Flex feeder accommodates multiple parts is an automated equipment specially used for conveying various small parts, electronic components, and medical equipment accessories. It is not limited by the complexity of part shapes, fragility, and production replacement requirements, and can provide a variety of small batches and fast switching production modes.

Advantages of flexible feeding manipulator platform:

1. Flex feeder accommodates multiple parts uses an all-aluminum modular body, and adopts an integrated design of motor, backlight, and direct vibration drive control for replenishing bins.

2. The entire series of automatic flexible vibrating plate is equipped with tomition voice coil motors as standard, with a motor life of more than 5 years, and the vibration parameters of the same model of vibration plates are exactly the same.

3. The flexible feeding manipulator platform has high stability, and the no-load noise is less than or equal to 60 decibels.

Parameters of flex feeder accommodates multiple parts:

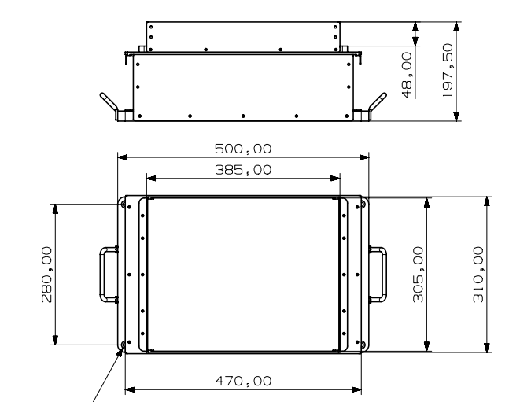

The dimensions of flex feeder accommodates multiple parts are 500310197.5 (mm), the internal dimensions of the feed tray are 385*305 (mm), the standard height of the sidewall is 48mm and 55mm, and customization is supported. The weight of the automatic flexible vibrating plate is 34kg, and the working power supply is dc24v/8a. The vibration frequency is consistent with the same model of vibrating plate, and the working frequency of different materials is also the same. The no-load noise of the flexible vibrating feeder platform is ≤75 decibels, the maximum load-bearing capacity is 3kg, and it is suitable for fine parts of 10-25mm, and the maximum flippable weight is ≤80g. The single action beat of the flexible feeding manipulator platform is 150-300ms, and it adopts vertical vibration dispersion, gathering, and one-way movement mode around. Built-in adjustable white backlight, built-in control driver board, circuit isolation, npn input and output, multi-waveform control, support tcp/ip communication and io control.

Industry application:

Flexible feeding manipulator platform is mainly used in various industries such as electronics, hardware, plastics, watches, batteries, food, connectors, medicine, food, toys, stationery, semiconductors, magnetic cores, fpc, etc. The applicable shapes of flex feeder accommodates multiple parts are sheet, o-type, u-type, l-type, needle-shaped, granular, strip, square, cylindrical, tower-shaped, cone-shaped and other irregular shapes. And its applicable materials include plastic parts, hardware parts, rubber parts, electronic parts, ceramic parts, silicone parts, stamping parts and other small parts of composite materials. It is also applicable to some parts with special requirements, such as parts that are easily damaged by surface coating, oil-containing parts, electroplating parts, etc.

About us:

Shenzhen Hongcheng Automation Equipment Co., Ltd. is an enterprise integrating R&D, manufacturing, sales and after-sales service of automatic feeding system (vibration plate). Our vibration plates and automation equipment are widely used in light industrial machinery, standard parts, connectors, bearings and other industries.