Product overview:

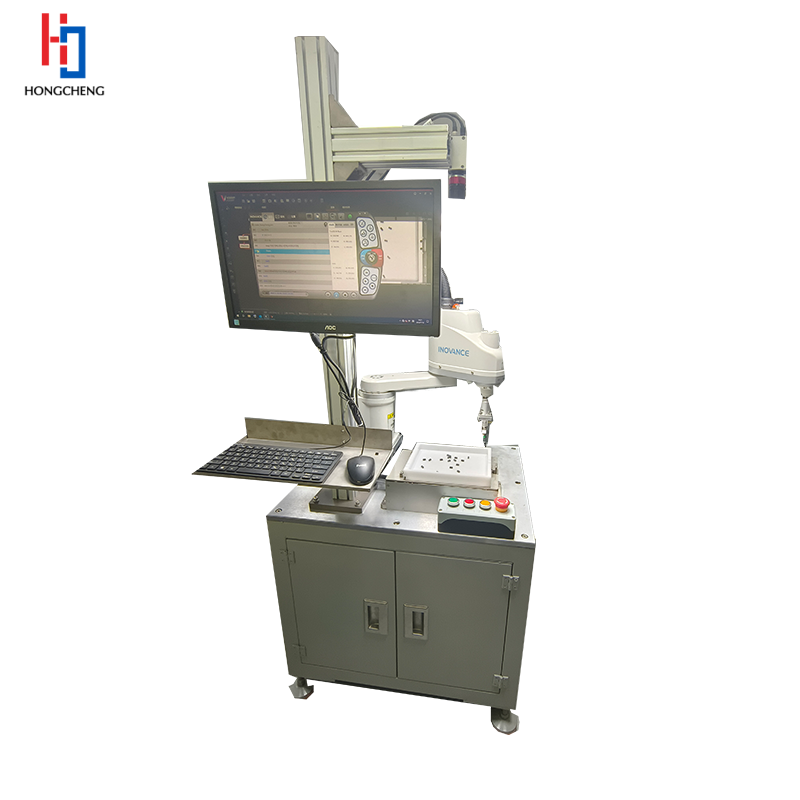

Flexible feeding for assembly automation is a device that automatically conveys various small parts. It is widely used in manufacturing industries such as electronics, hardware, connectors, medical equipment, and medicine. It is used for arranging and loading small parts in bulk in automated production. It not only reduces labor intensity, but also improves the flexibility of flexible feeding systems.

Product advantages:

1. Flexible feeding for assembly automation adopts dc24v system, electrical isolation, emc, and multi-waveform combination control, which improves its stability and high safety.

2. Flexible feeding systems can complete vibration debugging and parameter setting in a short time, and supports network port communication and passive io control.

3. Automated parts feeding platform adopts modular design, which can increase its use speed.

Parameters of flexible feeding systems:

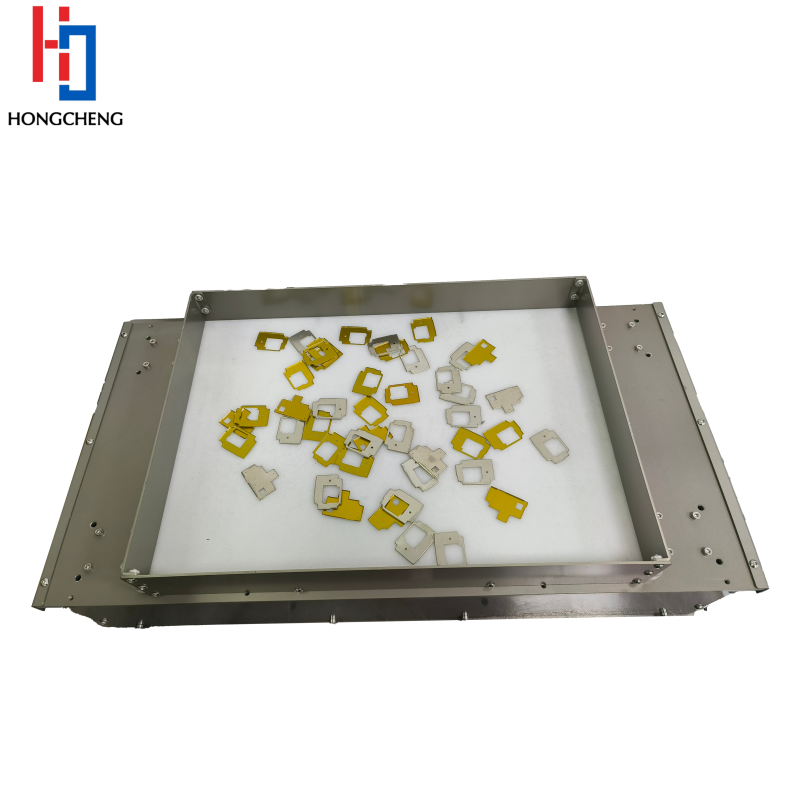

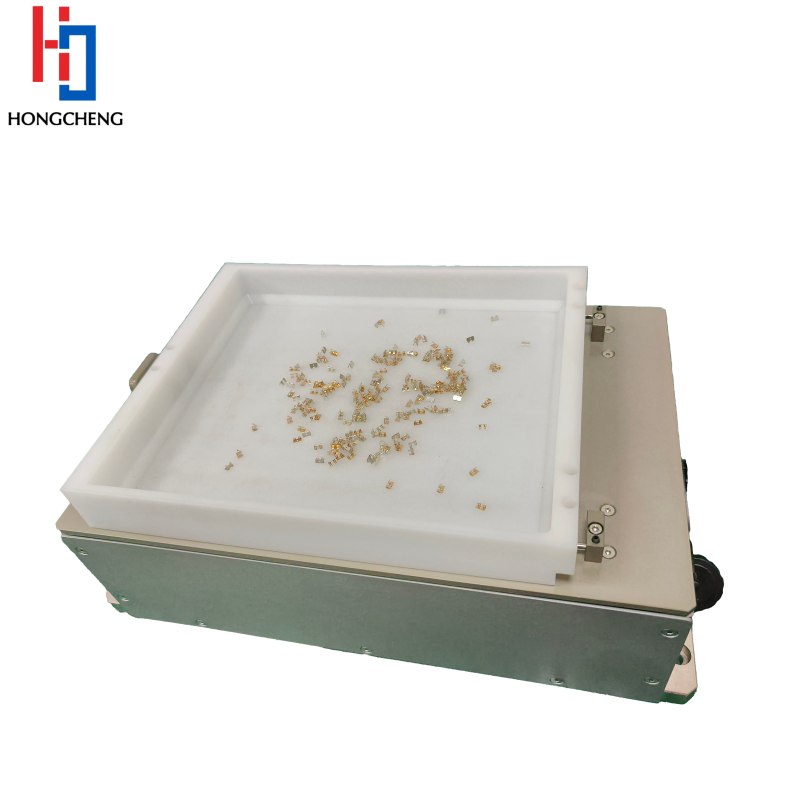

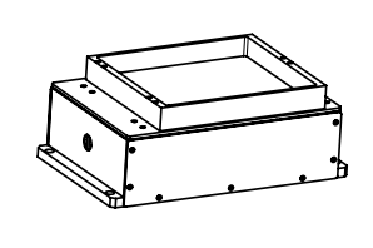

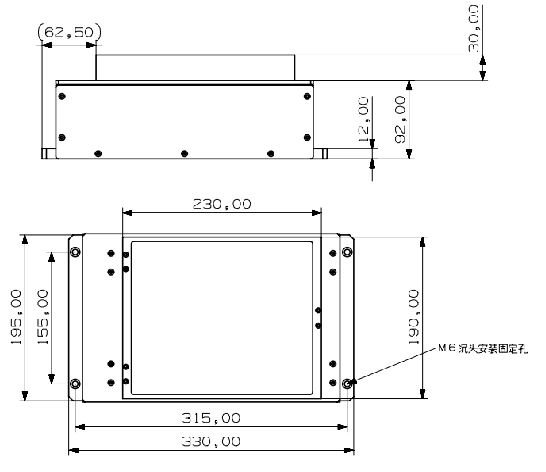

1. Equipment size: The external dimensions of flexible feeding for assembly automation are 330*195*122 (mm), and the internal dimensions of the tray are 230*190 (mm).

2. Sidewall height: Standard 30mm, 40mm (customizable)

3. Equipment weight and power supply: The weight of flexible feeding systems is 8kg, and the working power supply is dc24v/8a.

4. Vibration frequency: The vibration frequency of flexible vibrating feeder platform is consistent with the same model equipment, and the working frequency is also consistent for different materials.

5. Noise and load-bearing capacity: No-load noise ≤65 decibels, maximum load-bearing capacity 1.5kg, suitable for 5-20mm precision small parts, and the maximum flip weight of a single part ≤50g.

6. Action mode: The single action rhythm of flexible feeding manipulator platform is controlled at 200-400ms, and vertical vibration dispersion, gathering, and one-way movement around are adopted to ensure uniform feeding.

7. Backlight and control: Flexible feeding systems has built-in adjustable white backlight, built-in control driver board, circuit isolation design, npn signal input and output, multi-waveform control method, and supports tcp/ip communication and io control method.

Installation and debugging method of flexible feeding for assembly automation:

Before we officially install the flexible feeding systems, we need to do some preparatory work. First, we need to fix the installation position of the feeder to avoid affecting the accuracy of the vibration. Then connect the power supply that matches the voltage of the flexible feeding systems and meets safety standards to check whether the automated parts feeding platform system can operate normally. Then set the vibration frequency and amplitude, and adjust the parameters so that the automated parts feeding platform system can correctly detect the position and direction of parts. Perform multiple tests to ensure that the feeding speed can meet production requirements. Observe the operating status of the automated parts feeding platform. It can be used normally without abnormal noise or jamming.

About us:

Shenzhen Hongcheng Automation Equipment Co., Ltd. focuses on the research and development, manufacturing and sales of automatic feeding systems (vibration plates) and non-standard automation equipment. The company has advanced equipment, a complete design system, and fine manufacturing technology, and can provide high-quality services. The main products include automatic feeding vibration plates, automatic feeding bins, precision aluminum plates, flexible platforms, centrifugal equipment, etc.