Product introduction of Flexible Part Feeding System:

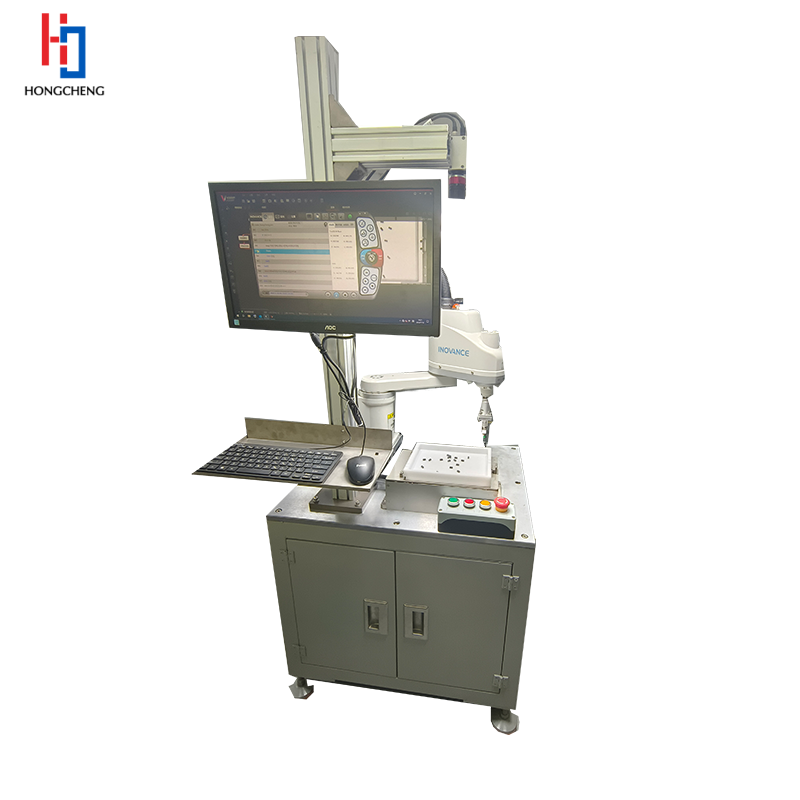

Flexible Industrial Manipulator is a system for feeding/loading parts into the manufacturing process. Flexible Feeding manipulator includes a feeder for handling and feeding parts, a vision system and a robot for positioning parts for the next process. Flexible Feeding manipulator can overcome the high cost of traditional parts feeding by loading parts of various sizes, shapes and directions.

Product advantages of Flexible Part Feeding System:

Flexible Industrial Manipulator can be applied to various thin sheets, special shapes, and small parts with surface coatings that are afraid of scratches. Flexible Industrial Manipulator can realize multi-variety sharing and fast material switching to meet the changes in different products and production needs. Flexible Feeding manipulator can achieve reliable and accurate part detection. The Flexible Industrial Manipulator we produce integrates the three functions of feeding, vision, and grabbing and transferring, which improves the convenience of operation and production efficiency.

Operation process of Flexible feeding and flexible assembly systems:

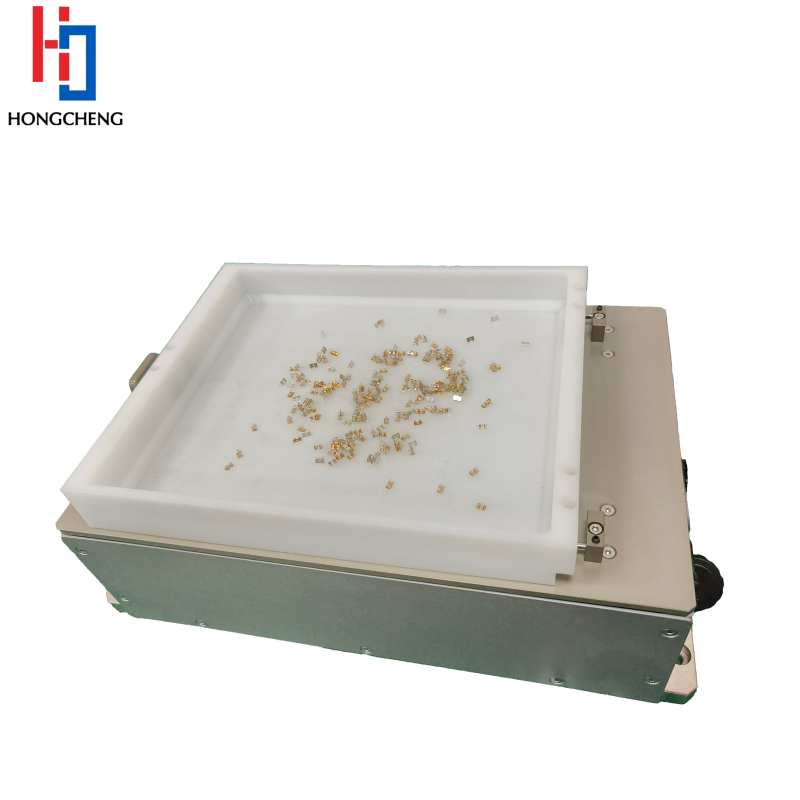

Flexible feeding and flexible assembly systems will first send the material to the vibration plate in a slow vibration manner, and control the vibration through the program to achieve the gathering, separation, and separation of the material, so that the product reaches the appropriate state and direction. The material feature information is obtained through the visual recognition system, and the material is accurately positioned and picked up. Finally, the manipulator grabs according to the data information of visual recognition to ensure high efficiency while improving product accuracy.

Maintenance and care of Flexible feeding and flexible assembly systems:

Flexible Feeding manipulator maintenance and care is the key to ensure the long-term and stable operation of the equipment. In daily use, dust and debris on the vibration plate and conveyor track should be cleaned regularly to prevent material blckage or contamination. Lubricant should be added to the vibration motor regularly to reduce wear. Before using Flexible Feeding manipulator, check the bolts and screws that tighten the vibration plate, conveyor track and other components. Finally, the control system such as PLC and sensors should be checked regularly to ensure normal operation.

Product parameter description of flexible feeding manipulator:

| Product name | Flexible Feeding manipulator |

| Appearance length*width*height (A*B*F) | 316*171*131 mm |

| Vibration plate structure design | Slot/Hole/Tooth/Brushed/Customized |

| Electrical parameters (feeder) | 24 V/ 6A |

| Electrical parameters (backlight source) | 24V/3A (output) |

| Debug software communication mode | Standard 232 serial port |

About us:

Shenzhen Hongcheng Automation Equipment Co., Ltd. specializes in the research and development, sales and service of non-standard automation equipment, especially flexible feeding systems. We use advanced technology, precise design and high-quality production, combined with the actual needs of customers, to provide a full set of automated feeding systems from centrifugal feeders to flexible feeding systems. Each product has undergone strict custom design to ensure that it perfectly fits the customer's production process, helping customers improve production efficiency, reduce manual operations, and improve the automation level of the overall production line.