In the hardware and electronics manufacturing industry, from small screws, springs, terminals to large metal accessories and electronic connectors, every component needs to enter the assembly process accurately and quickly. Electric or hardware components automatic vibratory bowl feeder is an automatic feeding device widely used in the hardware and electronics industry. It adjusts the components from a chaotic state to a unified direction through vibration, friction and guide mechanisms, and transports them to downstream processes such as automatic assembly, welding, packaging, etc.

In the hardware and electronics industry, automatic vibratory bowl feeders are mainly used to process small, regular or irregular parts, such as screws, nuts, washers, electronic terminals, connectors, small hardware, etc. These parts are small in size and diverse in shape. Manual feeding is time-consuming and error-prone. Our vibratory bowl feeders for automated assembly can complete the feeding efficiently and accurately, ensuring that the production line can run smoothly.

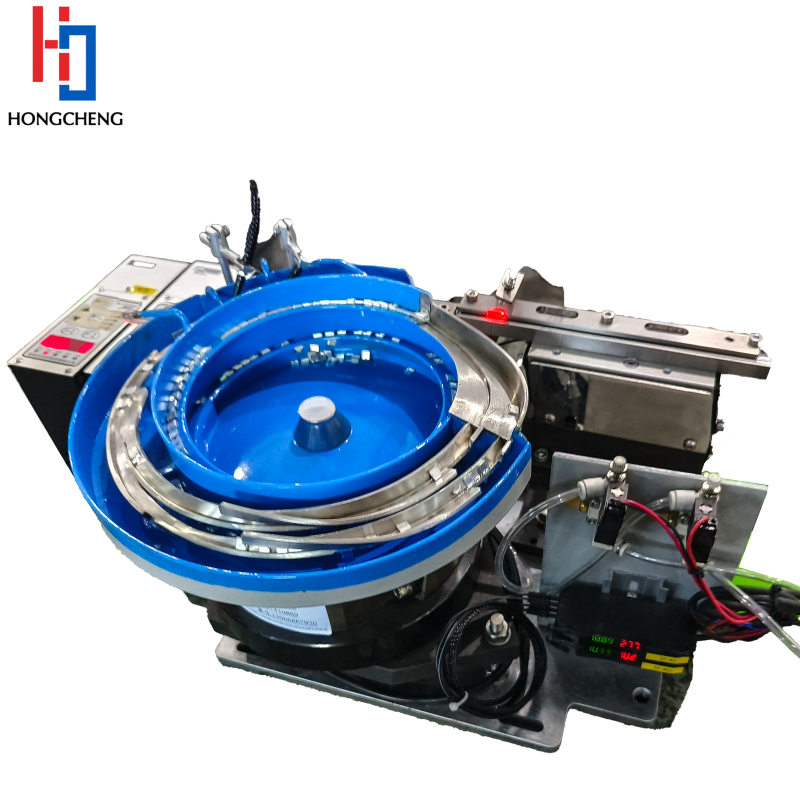

The working principle of vibratory bowl feeder for electronic components is to drive the parts to move along a specific track through electromagnetic vibration to achieve automatic sorting and transportation. The hardware or electronic parts to be processed are randomly put into the hopper of vibratory bowl feeder for precision components, and a vibration drive device is installed at the bottom of the hopper. After the electric or hardware components automatic vibratory bowl feeder is started, the vibration drive device generates high-frequency vibration. Vibratory bowl feeder for precision components pushes the parts to move upward and is arranged neatly through a specific track.

The inner wall of automatic vibratory bowl feeders is equipped with tracks of different angles and shapes to adjust the direction of parts. For example, screws need to have threads facing down and terminals need to have pins facing outward. During the track screening process of automatic vibratory bowl feeders, parts that do not meet the direction requirements will be automatically removed or re-entered into the cycle until all parts are arranged in the set direction. The oriented parts enter the automatic assembly, welding or packaging equipment along the conveying track of vibratory bowl feeders for automated assembly. Vibratory bowl feeders for automated assembly can ensure the automated operation of the production line. And vibratory bowl feeder for electronic components can improve production efficiency.

In hardware and electronic manufacturing, traditional feeding methods mainly rely on manual placement, mechanical feeding or vibration plates, but these methods have problems such as uneven feeding, low efficiency, and high error rate. Our vibratory bowl feeder for electronic components can effectively solve these problems. Electric or hardware components automatic vibratory bowl feeder can not only feed continuously and uninterruptedly, but also adjust the direction of parts according to the set track to reduce assembly errors. Automatic vibratory bowl feeders can customize the track and vibration frequency according to the part specifications, and are suitable for parts of various shapes and materials, such as metal parts, plastic parts, electronic components, etc. If you need our vibratory bowl feeder for precision components, please feel free to contact us.