Connectors are widely used in automobiles, communication equipment, industrial control and other fields. Because connectors are small in size and require high precision, manual feeding is prone to problems such as unstable feeding and low production efficiency. As an automated feeding device, connector vibrate feeder can effectively control quality while improving production efficiency. Our connector vibrate feeder uses vibration and track guidance technology to automatically sort, orient and convey connectors. What problems can sound proof plastic connectors feeder vibratory solve for quality control in the connector production process?

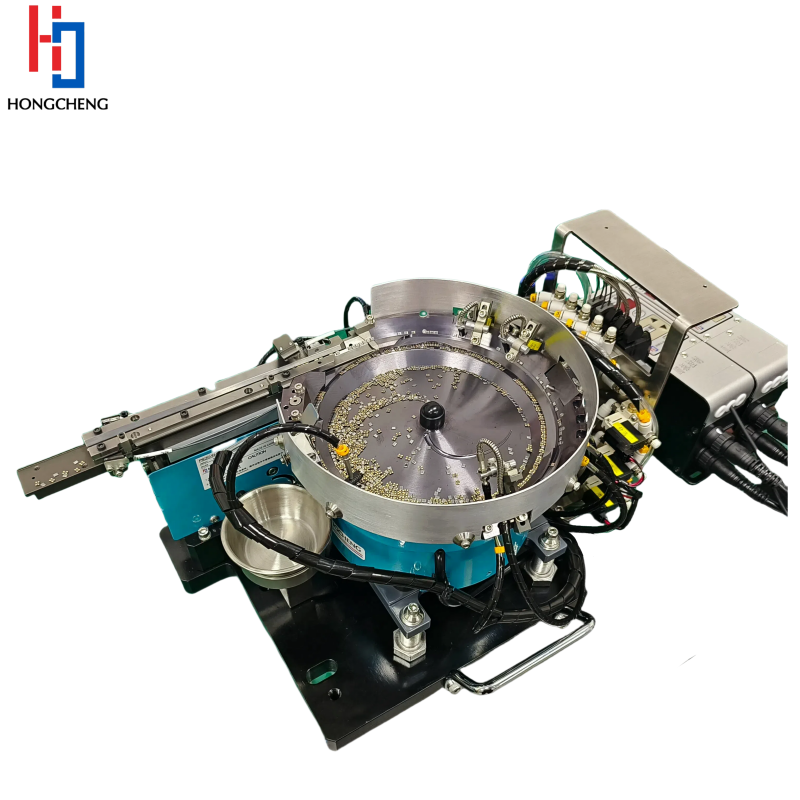

The size of connectors is relatively small, and the insertion direction and arrangement are very demanding. If the feeding direction of the connector vibrate feeder is wrong or the parts are tilted, the assembly quality of the connector will be affected. The connector vibrate feeder is designed with a special track structure for connectors of different shapes, so that the connectors are in the same direction when entering the next process. During the feeding process, sensors or mechanical screening devices are used to remove connectors with the wrong direction or overlap. If foreign matter or defective products are mixed in the process of conveying connectors, it will directly affect the quality of the final product. The sound proof plastic connectors feeder vibratory uses an integrated camera to identify unqualified connectors and remove them during the feeding stage. For metal connectors, magnetic sorting is used to remove foreign matter. For connectors made of plastic or other materials, optical detection is used to screen to ensure product quality.

During the production process, a stable feeding system can reduce the downtime rate of the plastic connectors feeder vibratory and improve production efficiency. The bowl feeder uses wear-resistant materials for the feeding track and vibrating chassis to reduce wear caused by long-term operation and increase the service life of the equipment. Some plastic connectors feeder vibratory are equipped with an automatic cleaning function to regularly remove residues on the track, allowing it to operate stably for a long time.

Our sound proof plastic connectors feeder vibratory can ensure the accuracy of the connector in the subsequent assembly process through precise feeding, reducing assembly errors caused by improper feeding. Our connector vibrate feeder can also reduce manual placement errors, reduce the probability of defective products entering the production line, and reduce the probability of rework and scrap. Our connector vibrate feeder uses a continuous and stable feeding method to speed up the overall production rhythm. Plastic connectors feeder vibratory can also customize tracks and screening devices according to different types of connectors to meet the feeding needs of various shapes and sizes. If you need our products, please contact us.