Introduction to vibratory bowl feeders for automated assembly:

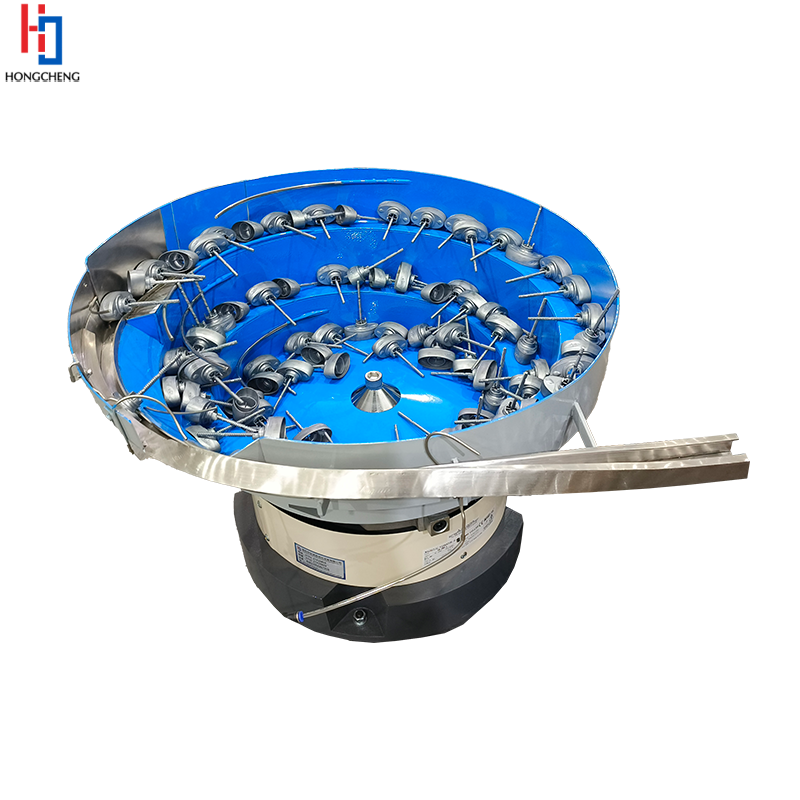

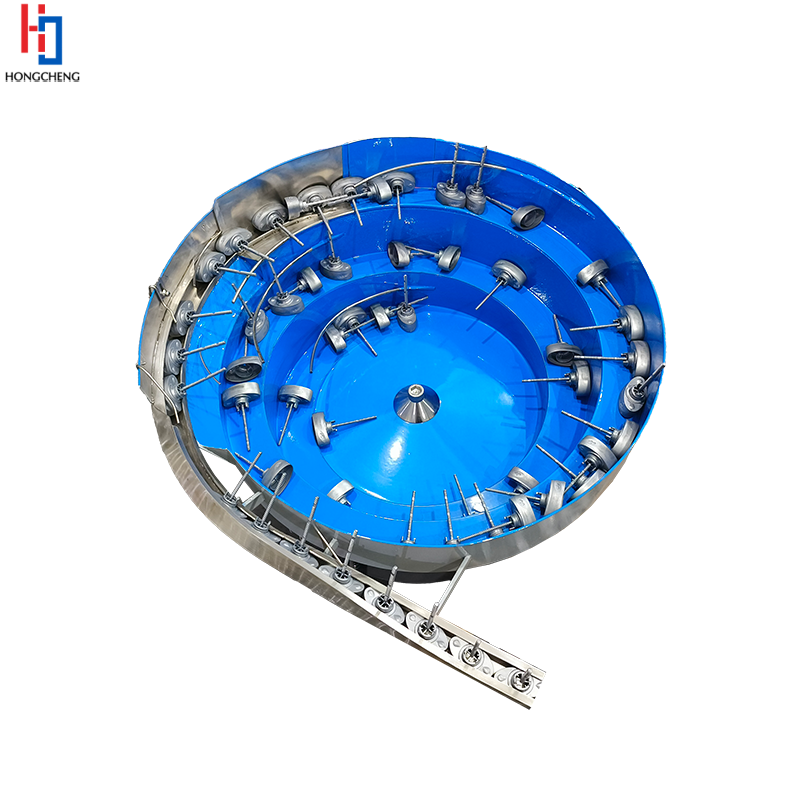

Vibrating bowl feeder for computer connectors are a feeding device designed for the automated production of connectors in the electronics, automotive, communications and other industries. Vibrating bowl feeder for computer connectors use vibration to arrange connectors in an orderly manner and accurately transport them to the next process, reducing manual intervention, improving production efficiency and ensuring product consistency. Our vibratory feeders for aerospace industry is suitable for connectors of various specifications, such as board-to-board connectors, terminal connectors, circular connectors, etc. We can customize the bowl size, track structure and vibration frequency according to different connector shapes and production requirements.

Advantages of vibratory bowl feeders for automated assembly:

1. The vibrating bowl feeder for computer connectors adopt an optimized track design and a stable vibration system to ensure that the connectors are arranged in the correct direction and transported smoothly.

2. Vibrating feeder bowls for automotive connector can be applied to connectors of different types, sizes and shapes, such as terminals, board-to-board connectors, circular connectors, etc.

3. Vibratory feeders for aerospace industry can customize the bowl size, track width and vibration parameters according to your needs

Parameters of vibratory bowl feeders for automated assembly:

Applicable Industries: | Electrical Industry | Condition: | New |

| Voltage: | 220v | Certification: | |

| Place of Origin: | Shenzhen, China | Material Characteristics: | High Degree of Automation |

| Warranty: | 1 Year | Product Name: | Vibrating Bowl Feeder for Computer Connectors |

How vibratory bowl feeders for automated assembly work?

An electromagnetic vibrator is installed at the bottom of the Connector vibrate feeder. When powered on, the vibrator generates high-frequency vibrations, driving the bowl to vibrate together. The force of vibration allows the connector to move continuously in the bowl and gradually be transported to the track exit. The bowl and track of the Vibrating feeder bowls for automotive connector will guide them to be arranged in the correct direction according to the shape and center of gravity of the connector. When the connector moves to the exit, it can be combined with a photoelectric sensor or a visual inspection system to ensure that the connectors are arranged correctly and transported in sequence. If the Plastic Connectors Feeder Vibratory detects an incorrect connector, the system will automatically remove it to avoid affecting subsequent production processes. The neatly arranged connectors pass through the track exit and are transmitted to the next process.

How to optimize vibratory feeders for aerospace industry?

1. During use, the motor control of the vibrating feeder bowls for automotive connector can be accurately controlled by frequency conversion speed regulation, phase and amplitude adjustment.

2. We can also regularly check and maintain whether the motor is in good working condition. According to production needs, we can adjust the angle, height and other parameters of the vibratory feeders for aerospace industry trough, change the material conveying direction and speed, and meet different production requirements.

3. We also need to regularly inspect and maintain the various components of the connector vibrate feeder to check whether the components are worn or damaged, and replace them in time to avoid danger.

Common problems and solutions:

1. When using the connector vibrate feeder, you may encounter situations where the connector is stuck or the conveying is not smooth. This is usually caused by improper vibration settings or obstacles in the conveying channel. We can first check the vibration system of the vibrating feeder bowls for automotive connector to confirm whether the vibration frequency and intensity are suitable for the specifications of the bottle, and at the same time clean the conveying channel to see if there are any foreign objects affecting the operation.

2. If the vibratory feeders for aerospace industry makes abnormal noise during operation, it is likely that the screws or components inside the equipment are loose or damaged. The screws and various components inside the equipment need to be carefully checked to see if they are loose or worn. For severely damaged parts, it is recommended to replace them in time to avoid affecting normal operation.

3. When the feeding speed of the connector vibrate feeder slows down, it may be caused by a motor or drive system failure. You can first check whether the motor connection wire is loose to confirm whether the motor can operate normally. If the problem is still not solved, it is recommended to contact the maintenance personnel to check the drive system to ensure that the vibrating feeder bowls for automotive connector resumes normal operation.

About us:

Shenzhen Hongcheng Automation Equipment Co., Ltd. specializes in automatic feeding systems, such as vibration plates, aluminum plates, flexible platforms, double centrifugal plates, feeders, etc. It also develops and sells non-standard automation equipment and provides related services. Our products are widely used in pharmaceuticals, hardware and electrical appliances, plastics and rubber, connectors, batteries, medical equipment, cosmetics, food packaging, semiconductor testing, electronic precision products and other industries to help companies improve production efficiency.