Automobile motors are important core components in the automobile manufacturing industry. Whether it is an engine starter motor, a window lift motor, or a wiper motor, etc., they all rely on precise production processes. In the production process of automatic vibratory bowl feeders motor for large vehicle parts machine, many small parts need to be fed automatically to ensure production efficiency. Automatic vibratory bowl feeders motor for large vehicle parts machine is an automatic feeding device specially used for sorting, orienting and conveying automobile motors. Automatic vibratory bowl feeders can use vibration and track design to arrange scattered parts in a set direction and smoothly and accurately feed them into the next process through the conveying pipeline.

The core components of automobile motors are stators and rotors, and their precise assembly can determine the performance of the motor. In the production process, the stators and rotors of vibratory bowl feeders for auto parts are usually composed of multiple parts, such as iron cores, coils, magnets, etc. Vibratory bowl feeders for auto parts can automatically sort and convey these parts so that they enter the assembly station in the correct direction. For example, the polarity direction of the magnet must be consistent. Vibratory bowl feeder for auto parts can use vibration and track design to arrange the automobile motor in an orderly manner. And vibratory bowl feeder for auto parts can enter the automated assembly system to reduce manual errors.

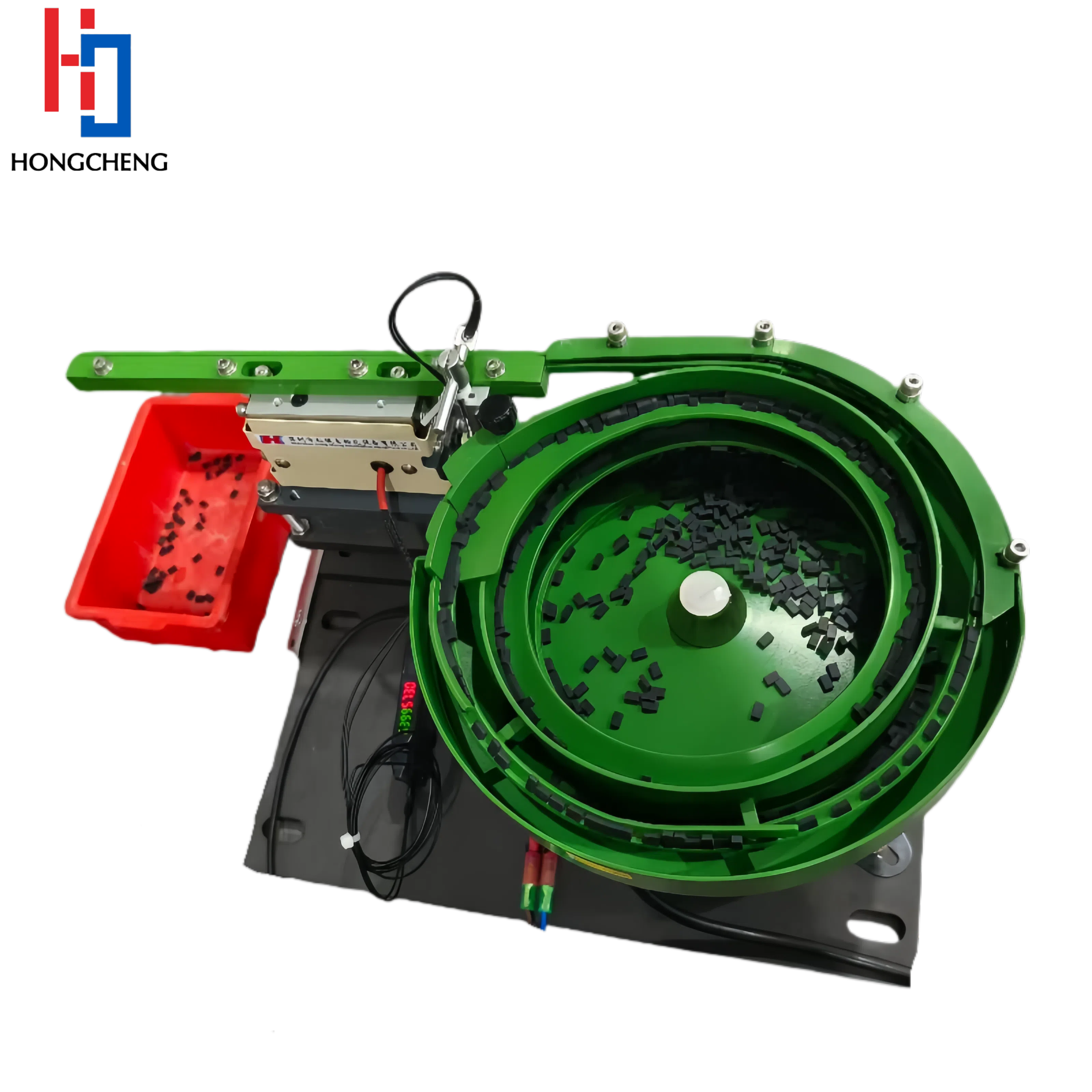

The stability and service life of the automobile motor are closely related to the bearings and shafts of the vibratory bowl feeder for auto parts. The traditional manual feeding method has problems such as low efficiency, wrong direction, and foreign matter mixing, and our vibratory feeder bowl for automotive plastic clips can solve these problems. For example, the ball bearings of the automobile motor need to be placed in a fixed direction. Vibratory feeder bowl for automotive plastic clips can use a specific track design to flip the bearings to the correct direction. And auto part vibratory bowl feeder stably feed them into the installation position.

In the manufacturing process of automobile motors, vibratory feeder bowl for automotive plastic clips can be used to organize and transport the fixing fixtures, insulating sleeves and lead terminals of the coils. For example, the feeding direction of the lead terminals is required to be consistent, otherwise it will affect the quality of welding. The auto part vibratory bowl feeder uses vibration arrangement and directional conveying to allow the terminals to enter the automatic welding equipment in the correct direction, improving the stability of the connection.

After the final assembly of the automotive motor is completed, quality inspection is required and qualified products are packaged. In this link, automatic vibratory bowl feeders can be used to convey labels, fix clips and packaging gaskets. For example, some automotive motors need to be installed with anti-vibration rubber pads. Our auto part vibratory bowl feeder can accurately convey these gaskets to avoid the unevenness caused by manual placement.Our vibratory bowl feeder for auto parts can adjust the bowl structure and track according to the size, shape and material of the motor parts. If there are special needs, we can also provide customized designs to adapt it to different products. Our auto part vibratory bowl feeder has strong compatibility, reduces the frequency of equipment replacement. And auto part vibratory bowl feeder improves production flexibility. If you need our products, please contact us.