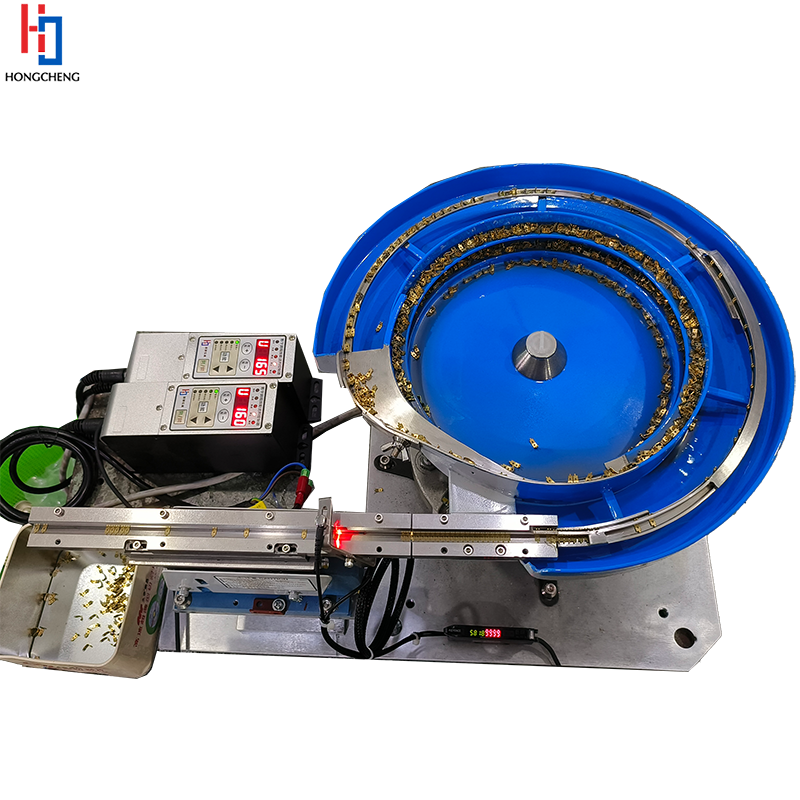

Product introduction:

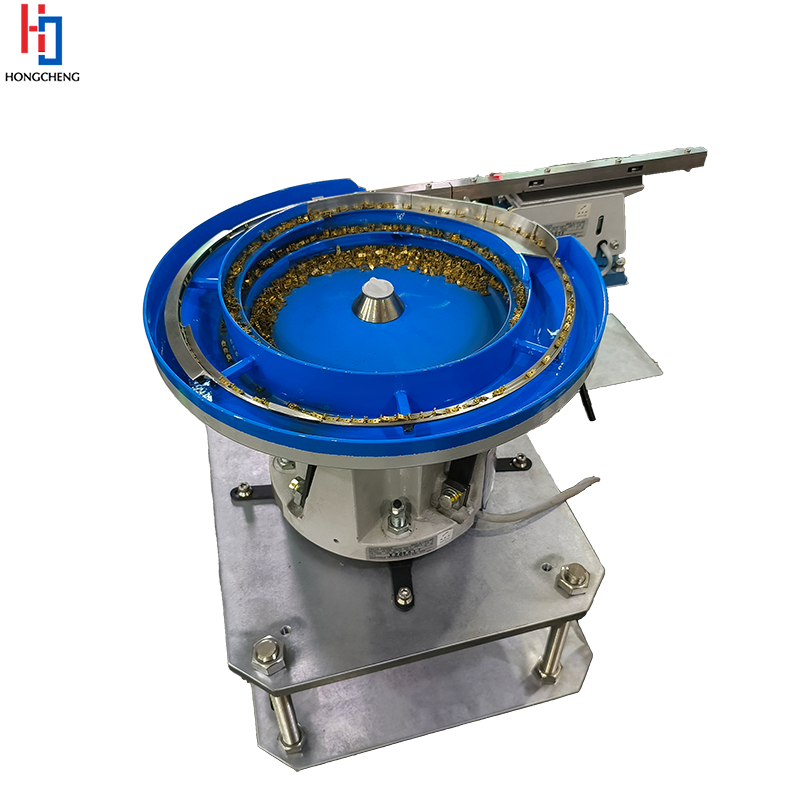

Vibratory feeder bowl for automotive plastic clips is an automatic feeding equipment specially designed for automobile parts production line, mainly used for conveying various types of motor parts, such as rotors, stators, bearings, end caps, etc. The auto part vibratory bowl feeder automatically arranges and directs automobile motors to the specified position through the principle of vibration. Automatic vibratory bowl feeders motor for large vehicle parts machine has a compact structure, stable operation, and can adapt to motor parts of different specifications.

Advantages of auto part vibratory bowl feeder:

1.Automatic vibratory bowl feeders is not only suitable for conveying automobile motor parts, but also can be used for automatic feeding of other automobile precision parts.

2.Vibratory bowl feeder for auto parts has a compact structure, small footprint, and convenient daily maintenance.

3.Vibratory feeder bowl for automotive plastic clips is fully automatic, does not require manual intervention, and saves labor costs.

Application of auto part vibratory bowl feeder:

In the production process of automobile motors, the parts inside the motor (such as stators, rotors, bearings, end caps, etc.) need to be accurately transported to the assembly position. Auto part vibratory bowl feeder can automatically arrange and transport these parts to ensure assembly accuracy and reduce errors in manual operation. In addition, more and more factories use robotic arms or robots for automated assembly. Automatic vibratory bowl feeders motor for large vehicle parts machine can accurately transport parts to designated locations, allowing robots to quickly grab them and improve the automation level of the entire production line. In the production process of automobile motors, automatic vibratory bowl feeders can also classify and feed materials according to the size and shape of different parts.

How to maintain vibratory bowl feeder for auto parts?

In order to make vibratory feeder bowl for automotive plastic clips more durable, we need to clean the bowl and the conveying channel regularly to prevent dust, dirt or bottle cap residues and ensure smooth operation. We also need to regularly check the vibration system of the auto part vibratory bowl feeder to ensure that the vibration frequency and intensity are set correctly. In order to reduce equipment wear, it is also necessary to regularly lubricate the rotating parts and check whether the screws and fasteners are loose.

Product parameters:

Applicable Industries: | Automotive Industry | Condition: | New |

Voltage: | 220V | Certification: | |

Place of Origin: | Shenzhen, China | Material characteristics: | Stable operation, low cost |

Warranty: | 1 Year | Product Name: | Automatic Vibratory Bowl Feeders |

FAQ:

1. What is the function of automatic vibratory bowl feeders motor for large vehicle parts machine?

Automatic vibratory bowl feeders is an automatic feeding device that can deliver motor parts (such as stators, rotors, bearings, end caps, etc.) to the production line neatly and orderly.

2. What motor parts are suitable for vibratory bowl feeder for auto parts?

It is suitable for a variety of automotive motor parts, including stators, rotors, bearings, end caps, small screws, etc.

3. Can vibratory feeder bowl for automotive plastic clips adapt to parts of different sizes?

Yes! And we can provide customized services.

About us:

Shenzhen Hongcheng Automation Equipment Co., Ltd. is a manufacturer specializing in automatic feeding systems. Its products include vibrating plates, aluminum plates, flexible platforms, double centrifugal plates and feeders. It also provides research and development, sales and services of non-standard automation equipment. Our equipment is widely used in various industries, such as pharmaceuticals, hardware and electrical appliances, plastics and rubber, connectors, batteries, medical equipment, cosmetics, food packaging, semiconductor testing, and electronic precision products.