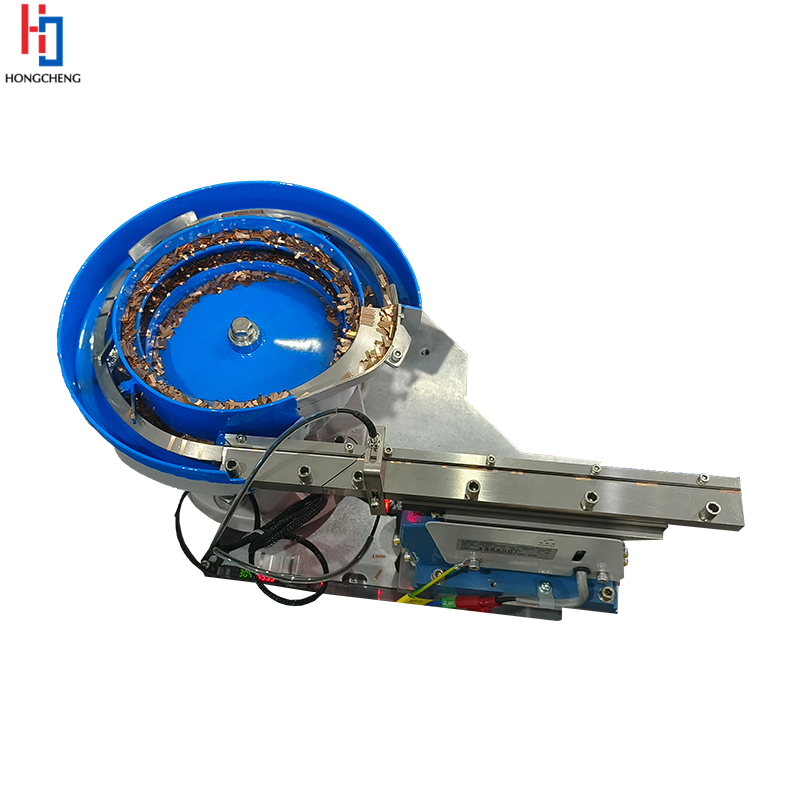

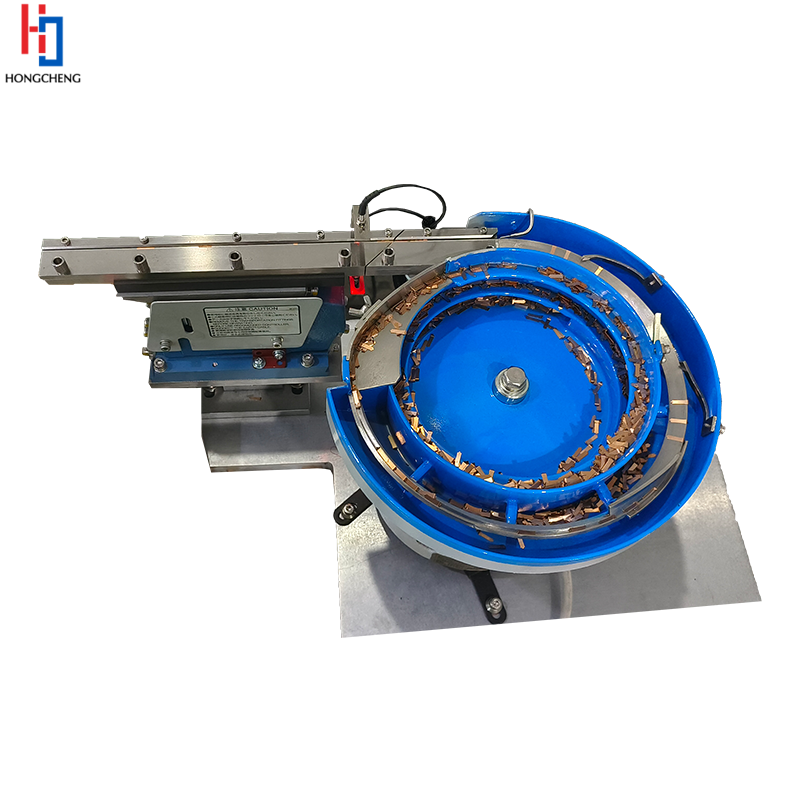

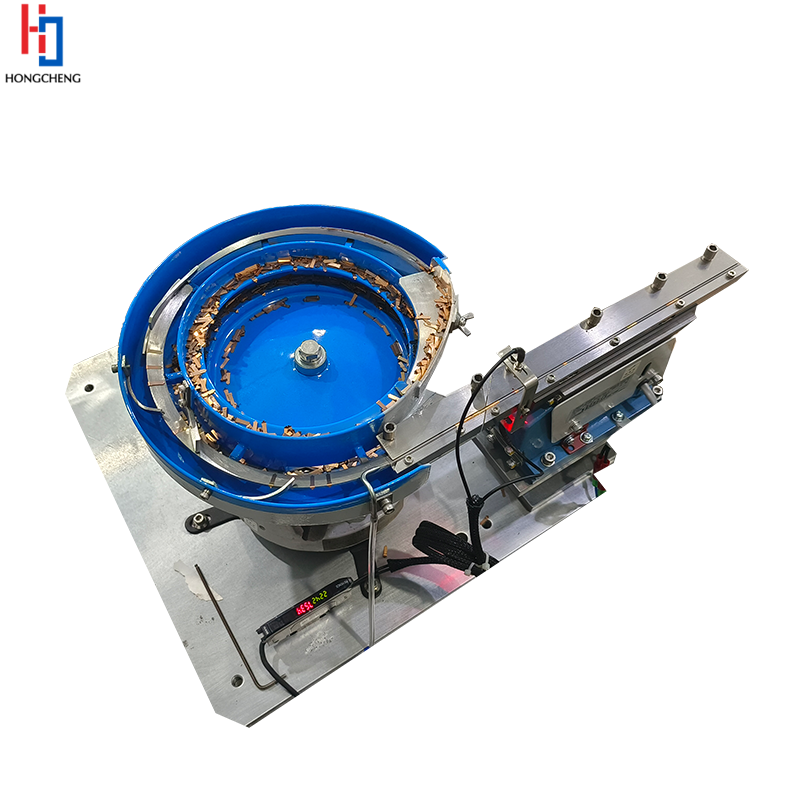

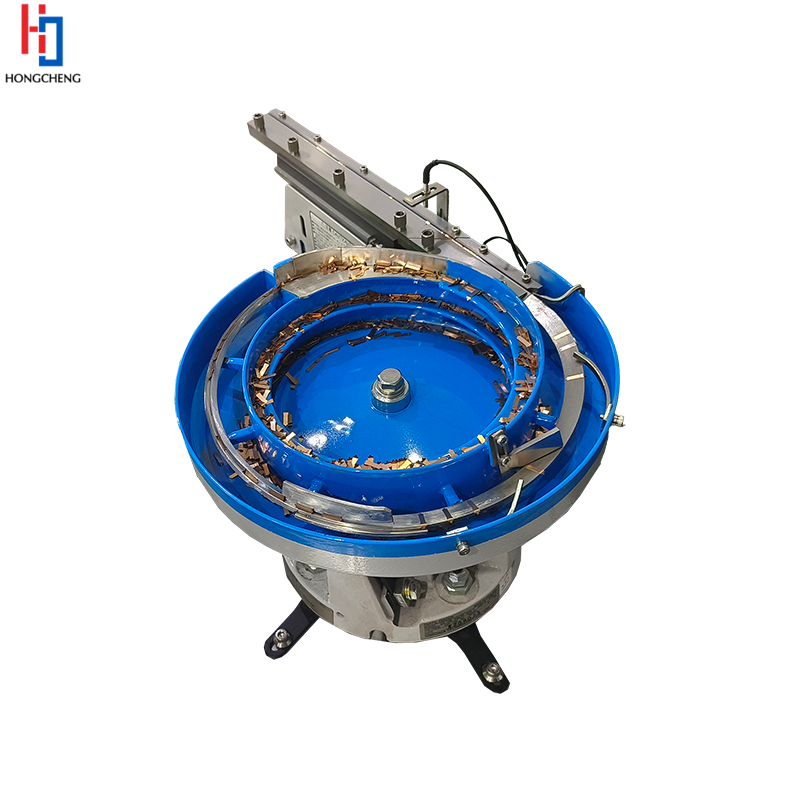

Product description:

Automatic vibratory bowl feeders is an auxiliary equipment used in automated production lines. It can transport scattered small components to the next process in a certain order. This equipment is particularly suitable for processing small components such as screws, washers, hardware and electronics. The vibration design of the electric or hardware components automatic vibratory bowl feeder can ensure that the material is evenly dispersed and reduce the deflection caused by gravity. In actual production, automatic vibratory bowl feeders may encounter adhesion problems such as static electricity, which can be solved by introducing ion wind nozzles to neutralize static electricity.

Product working process:

The feed port of the vibratory bowl feeder for precision components is usually located above the storage warehouse or silo of the material. The material enters the silo of the automatic vibratory bowl feeders by gravity or other means, and then waits for delivery. When the vibratory bowl feeders for automated assembly starts working, the motor will start and drive the conveying mechanism to start running. After the vibratory bowl feeder for electronic components starts running, the material will be delivered to the discharge port. The feeder vibratory bowl feeder for precision components is generally equipped with a control system, which we can adjust as needed.

Product application scenarios:

In the production process of hardware and electronic parts, the Electric or Hardware Components Automatic Vibratory Bowl Feeder can feed small hardware parts to the automated assembly line, such as the production line of common hardware products such as screws, nuts, washers, etc. In addition, automatic vibratory bowl feeders are also suitable for the feeding of various electronic components, such as the assembly lines of mobile phones, televisions, computers and other products. Vibratory bowl feeders for automated assembly are also suitable for the feeding of tiny components in the home appliance industry, such as batteries, connectors, circuit boards, etc.

Why choose our bowl feeders for hardware and electronics?

Our vibratory bowl feeder for electronic components can control the feeding of hardware and electronic components to avoid misplacement and waste. The vibratory bowl feeder for precision components uses high-strength materials, which are stronger and more durable than general products during use. In addition, the fully optimized design of our electric or hardware components automatic vibratory bowl feeder can reduce energy consumption and meet environmental protection requirements. If your product is a special size, we can also provide you with personalized customization services according to production needs.

FAQ:

1. What types of components are suitable for electric or hardware components automatic vibratory bowl feeder?

Our automatic vibratory bowl feeders are suitable for many types of hardware and electronic components.

2. How to maintain the vibratory bowl feeder for precision components?

Regularly check the vibration system, clean the debris in the bowl, check the operation of the motor, and ensure that the transmission system of the vibratory bowl feeders for automated assembly is fault-free.

3. Does the vibratory bowl feeder for electronic components support customized design?

Yes, we provide customized feeder services according to customer needs.

About us:

Shenzhen Hongcheng Automation Equipment Co., Ltd. is a manufacturer specializing in the research and development, sales and service of non-standard automation equipment for automatic feeding systems (vibration plates, aluminum plates, flexible platforms, double centrifugal plates, feeders). Our vibration plates and automation equipment are widely used in various industries such as pharmaceutical industry, hardware and electrical appliances, plastics and rubber, connectors, batteries, medical equipment, cosmetics and food packaging machinery, semiconductors and testing, and electronic precision products.