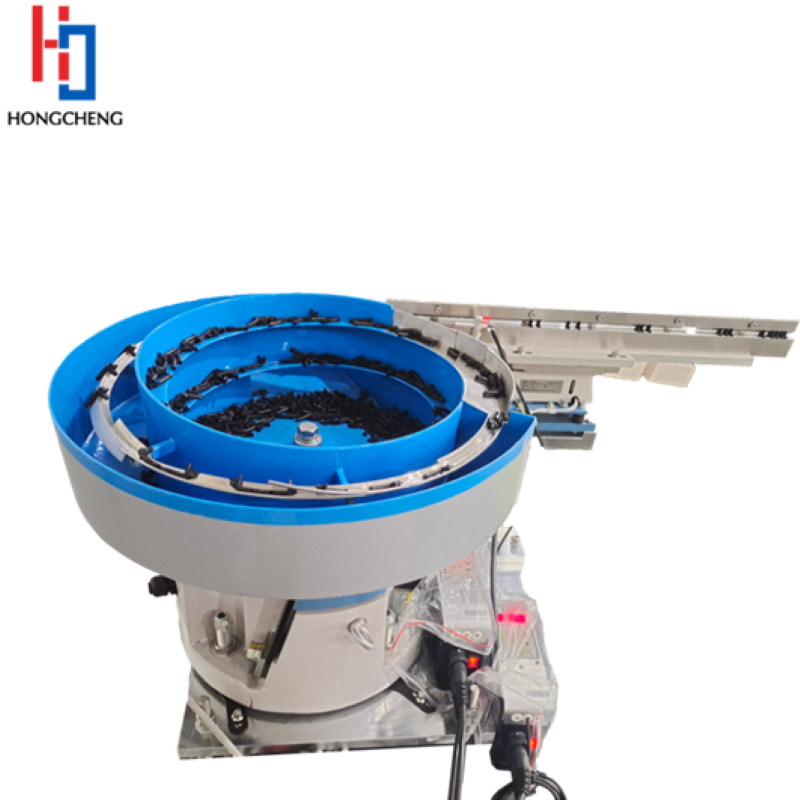

What parts can the vibrating bowl feeder for switch deliver? The keyboard and mouse switches we use daily, key control components of automobiles, precision instrumentation contacts, and vibrating bowl feeder for switch can all be delivered smoothly to improve the efficiency of the production line.

Our vibrating bowl feeder for switch can smoothly transport many electronic switch parts. The mechanical shaft switch of the keyboard, the micro switch of the mouse, and various switch contact parts inside electrical appliances such as washing machines and refrigerators can all be transported through the vibrating bowl feeder for switch. These parts may be of special materials and irregular shapes, but vibrating bowl feeder for switch can adjust the vibration frequency and amplitude according to the characteristics of different parts to make the conveying process smoother.

Our vibrating bowl feeder for switch also has an anti-static design and track treatment, so that these precision electronic components will not be damaged during transportation. In automobile manufacturing, door switches, wiper switches, central control buttons and other components that need to be accurately installed can also be fed using our vibrating bowl feeder for switch.

Our company provides customized solutions. Our micro-open vibrating bowl feeder uses a special low-frequency micro-amplitude vibration mode, which can deliver even easily damaged glass contacts or miniature sensors lossless. Our technical team will customize the track structure and vibration parameters according to customer requirements. For example, high-frequency vibration is used when dealing with metal switches, while plastic switches use low-frequency modes to meet the different needs of customers. Our customized services allow our vibrating feeding system for switch contacts to adapt to the needs of different industries and different production scenarios, improving production efficiency and reducing production costs for many companies.

Our company pays special attention to the details of the vibrating feeding system for switch contacts, such as the use of silencer materials in key parts to reduce working noise, and the use of scratch-resistant coatings on the contact surfaces. Each vibrating feeding system for switch contacts is rigorously tested before leaving the factory to ensure stable operation after delivery.

Shenzhen Hongcheng Automation Equipment Co., Ltd. it is a manufacturer engaged in the research and development, sales and service of non-standard automation equipment for bowl feeding systems. We will also continue to increase investment in R&D and launch smarter vibration feeding solutions. If you want to purchase a reliable vibrating feeding system for switch contacts, please feel free to contact us. We have rich industry experience and a perfect after-sales system, and I believe we will become your trusted partner.