When many customers choose a bowl feeder, the most important issue they are concerned about is whether it is noisy during operation? Especially on production lines that need to run for a long time, the noise of the feeder is directly related to the work experience of the operator. Our factory produces both aluminum Bowl Feeder Vibrating and plastic Bowl Feeder Vibrating as needed. Each has its own advantages and the noise level is also different. The Hongcheng factory will introduce the noise situation to you from the perspective of a professional manufacturer.

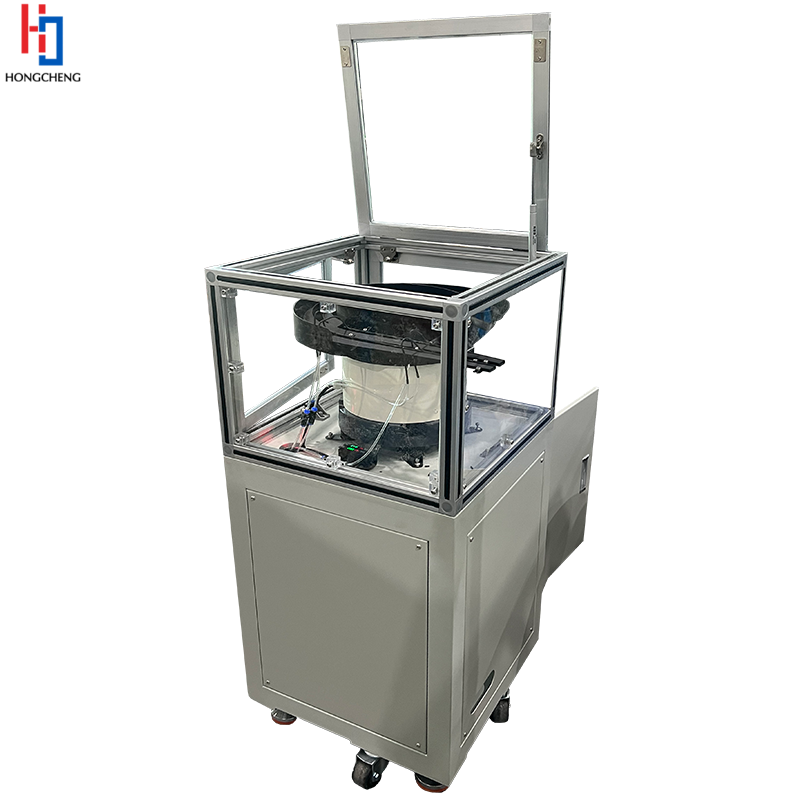

The overall structure of the cast aluminum vibratory feeder bowl is more stable, and the vibration frequency during operation is more controllable, so the noise is easier to concentrate and handle. With our specially designed silent cover and rubber shock pad, it can maintain a low noise level even when running at high speed.

When Bowl Feeder Vibrating is running, it is easy to resonate due to its light material. If it is not soundproofed, the sound will be slightly louder, but we can also effectively control the noise by thickening the bowl body and customizing the optimized base structure.

In fact, both Bowl Feeder Vibrating materials we produce can run relatively quietly. The key to how to choose lies in the application scenario and structural design. For example, Bowl Feeder Vibrating performs better in the precision electronics industry with high weight requirements, while cast aluminum vibratory feeder bowl is more suitable for conveying medium and large parts such as hardware and fasteners.

\

Our engineers took noise control into full consideration when designing Bowl Feeder. Each device supports customized installation of multiple silent solutions such as silent covers, shock-absorbing springs, and sound-absorbing cotton, and users can choose according to the factory environment.

In addition to standard models, our biggest advantage is non-standard customization capabilities. Whether the customer's materials are screws, buttons, or special-shaped metal parts, we can repeatedly test the most suitable bowl structure and track system based on size, weight, material, discharge frequency and other information to maximize the overall feeding efficiency and maintain smooth operation.

If you have special requirements for noise, we also welcome you to leave a message to communicate and tell us your usage scenarios so that we can recommend more suitable products for you. We also support customization based on drawings to tailor a suitable cast aluminum vibratory feeder bowl for you.