Using cosmetics centrifugal feeder to transport small parts such as lipstick tubes and powder boxes, can it really improve the feeding speed? The professional cosmetics centrifugal feeder can achieve high-speed delivery and maintain stable feeding, which improves the efficiency of cosmetic production lines.

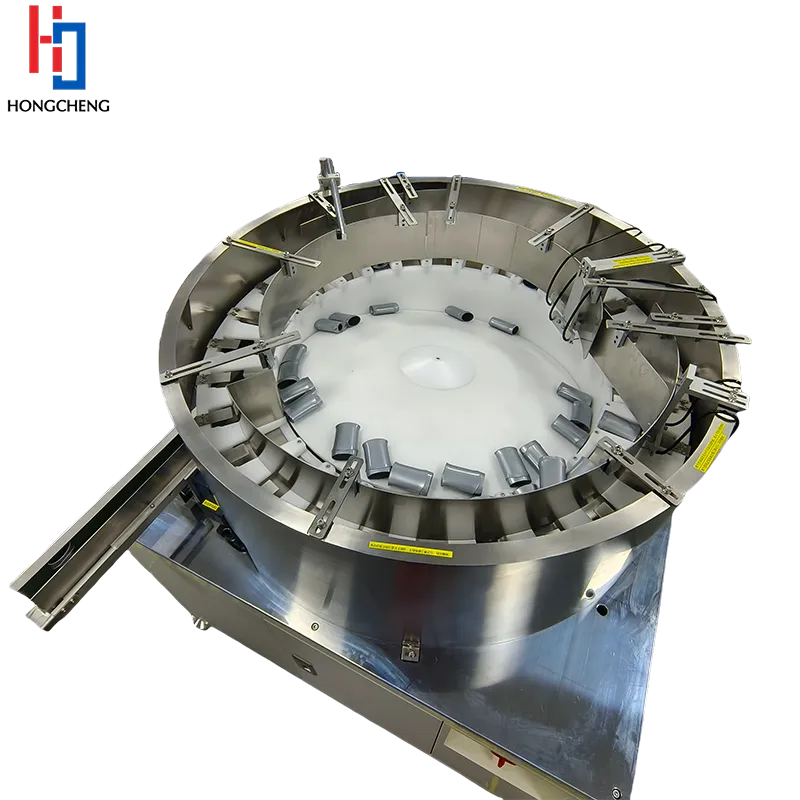

Our cosmetics centrifugal feeder uses unique technology, which is particularly suitable for handling a variety of special-shaped small parts. For perfume bottle caps with a diameter of 5mm, or eyeshadow palettes with complex shapes, our cosmetics centrifugal feeder can be quickly separated and oriented. Compared with traditional vibrating discs, our centrifugal design has a much higher conveying speed and is not affected by the surface of the parts. Our cosmetics centrifugal feeder is equipped with a speed control system, which can adjust the rotation speed according to the parts of different materials, and the suitable conveying speed can be found for cosmetic parts made of acrylic, glass, metal, etc.

Each of our glass bottle centrifugal feeders is made of medical-grade materials and meets the hygiene standards of cosmetic production. Our design team will test according to the specific parts of the customer, from the tilt angle of the turntable to the discharge track, every detail will be debugged. For special-shaped cosmetic accessories, such as lipstick tubes with buckles or special-shaped puff boxes, we provide customized solutions so that each part can be shipped correctly.

Our company has a dust-free production workshop, which is specially used for the assembly of feeding equipment. In addition, the glass bottle centrifugal feeder must pass continuous operation tests before leaving the factory to ensure stable performance in long-term use. We also provide customized services, because the production process and part shape of each cosmetics company are different, and it is difficult for general-purpose equipment to meet the actual production needs. Based on the parts samples provided by the customer, we will analyze the material, shape, weight and other parameters to design the size, speed and angle and width of the centrifugal disc on the glass bottle centrifugal feeder. For example, for eyeshadow box parts with small grooves, we will set up a corresponding guide device on the discharge track to allow the parts to enter the next production link correctly and improve the overall production efficiency.

Shenzhen Hongcheng Automation Equipment Co., Ltd. It is a manufacturer engaged in the research and development, sales and service of non-standard automation equipment for bowl feeding systems. We will continue to optimize the performance of the equipment and launch a better centrifugal feeding system. If you are interested in our glass bottle centrifugal feeder, please feel free to contact us. We will provide you with professional services to meet your needs.