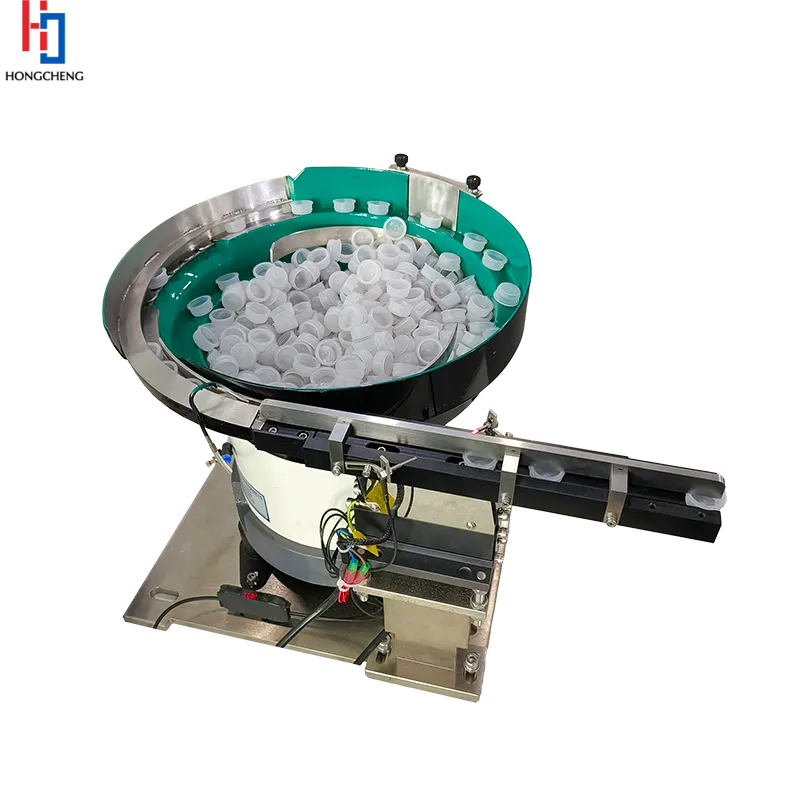

Production efficiency and product safety in the manufacture of infant products are very important. Many baby bottle manufacturers are very concerned about whether the production of baby bottle caps is suitable for the use of vibrating feeders? Our automatic vibrating feeding system is specially designed for baby bottle production lines, which can not only achieve high-speed and accurate delivery of bottle caps, but also ensure the hygiene and safety of products during delivery.

Our company attaches great importance to the hygiene and safety of the vibratory feeder system for plastic baby bottle caps. All parts in contact with the bottle cap are made of food-grade materials, and the surface is specially treated to prevent scratches on the product. Our equipment can be quickly disassembled and cleaned, which meets the requirements of production standards. Our design team will provide customized solutions such as dustproof and anti-static according to the customer's production environment, so that the vibratory feeder system for plastic baby bottle caps can adapt to the production requirements of the clean workshop.

The vibratory feeder system for plastic baby bottle caps has a control system installed, which can adjust the vibration frequency and amplitude, so that plastic bottle caps of different specifications can be delivered smoothly. The anti-jamming design of thevibratory feeder system for plastic baby bottle caps reduces the stacking or misplaced position of the caps during delivery. If it is equipped with a visual inspection system, damaged products can be removed. Only qualified caps can enter the next procedure.

We have a sound manufacturing system and quality control process. Each of our bottle cap feeder vibratory has undergone strict testing and hygiene testing before leaving the factory to ensure that it meets the safety standards of infant food contact materials. Bottle cap feeder vibratory can be adjusted according to production needs, providing a one-stop solution.

Our company can provide customized services. Through the parameter optimization of the control system, bottle cap feeder vibratory can handle bottle caps of different shapes and specifications. For special-size bottle caps, we will customize the vibration track so that the bottle caps can be transported smoothly. For production lines that require conveying speed, we will optimize the control system to stabilize the equipment and improve the conveying efficiency. We will monitor the bottle cap feeder vibratory during the production process. We also provide the correct bottle cap feeder vibratory installation video and operation guide, so that customers can install it correctly and easily.

Shenzhen Hongcheng Automation Equipment Co., Ltd. Will continue to innovate and develop safer vibration feeding solutions. If you are interested in ourbottle cap feeder vibratory , please feel free to contact us. We have rich industry experience and strict quality standards to meet your needs.