Centrifugal bowl feeders are an efficient automatic feeding equipment, which is widely used in electronics, automobiles, batteries, medical and other industries. Rotary feeder for battery parts can automatically sort and convey batteries, improve production efficiency, reduce manual intervention, and ensure that the production line can run stably. There are many types of centrifugal bowl feeders. How do we choose a device that suits our production needs?

When choosing a high feed rate centrifugal feeder system, it is mainly based on our own production needs. Different battery production lines have different requirements for feeding speed, accuracy and stability. It is necessary to clarify how fast the feeding speed of your battery production line needs? How many batteries are needed per minute? Can the feeding capacity of rotary feeder for battery parts meet the needs? Is the battery suitable for centrifugal bowl feeders? For example, small batteries are more suitable for centrifugal feeding, while larger batteries May require other types of feeding equipment. Only after clarifying the production needs can we choose the appropriate high feed rate centrifugal feeder system.

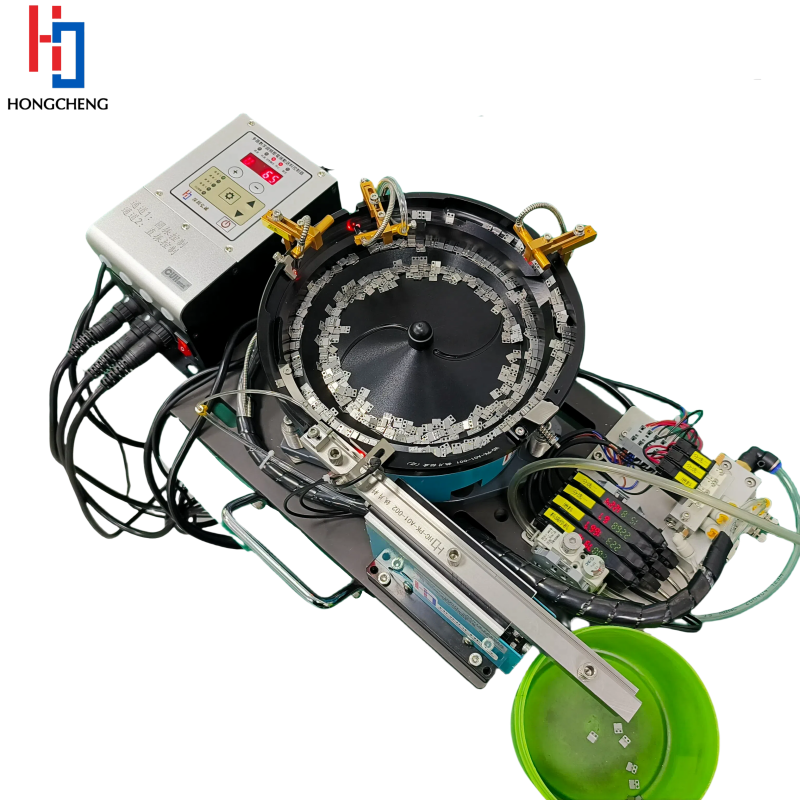

We also need to consider the compatibility of the rotary feeder for battery parts to see if it can adapt to different types of batteries. Our centrifugal bowl feeders can handle a variety of different sizes and shapes of batteries according to the needs of your battery production line. We can also provide customized services if you need them.The operation of the high feed rate centrifugal feeder system will also affect production efficiency. If the rotary feeder for battery parts often fails during use, it will not only affect the production progress of the battery, but May also cause losses.So we need to check whether the motor, control system, feeding track, etc. Of the centrifugal bowl feeders are made of high-quality materials. Will there be a problem of material jamming during the feeding process due to improper battery accumulation or arrangement? Can it be used for a long time?

In addition to the performance of the high feed rate centrifugal feeder system itself, we also need to understand whether it is easy to disassemble and clean? Can it be maintained regularly and quickly? Good after-sales service will also affect the use of rotary feeder for battery parts. Choosing the right centrifugal bowl feeders can not only improve production efficiency, but also reduce labor costs and reduce errors in the production process. Our high feed rate centrifugal feeder system can not only provide customized services, but is also widely used in various industries such as pharmaceutical industry, hardware and electrical appliances, plastics and rubber, connectors, batteries, medical equipment, cosmetics and food packaging machinery, semiconductors and testing, and electronic precision products.