In the production process of centrifugal feeders in automation, multiple key components (such as stators, rotors, bearings, end caps, etc.) need to be accurately and stably fed into the assembly process. If the feeding link of the adjustable speed centrifugal bowl feeder machine is unstable, it will not only cause the production line to jam, but also May affect the performance of the electric motor and reduce the safety of the product.

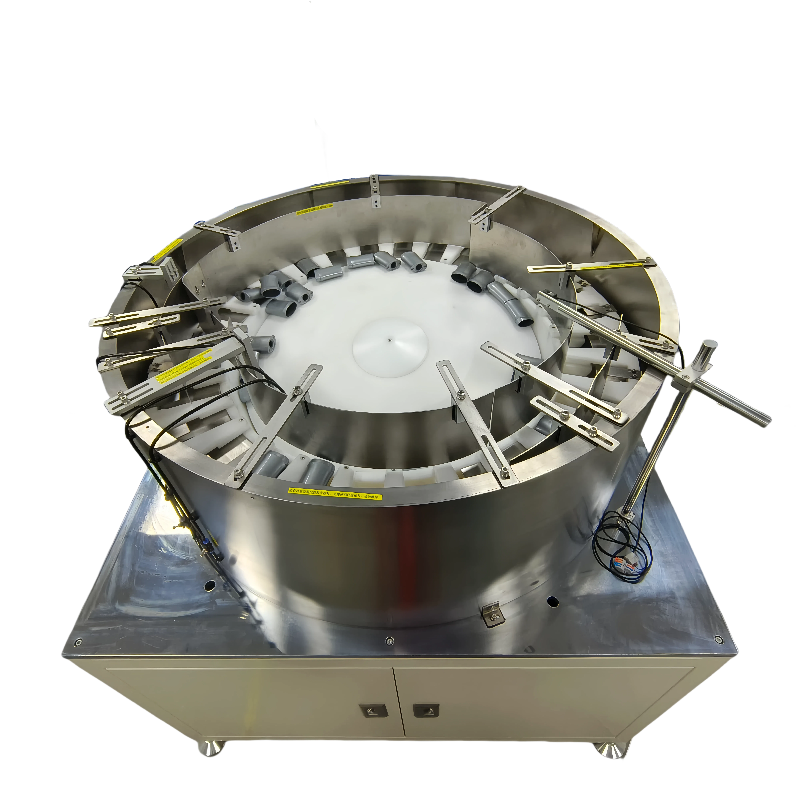

In the process of electric motor manufacturing, the adjustable speed centrifugal bowl feeder machine can increase the feeding speed of each electric motor component, and centrifugal feeders in automation are faster than traditional vibrating plate feeding methods. They can continuously and stably feed electric motor components into the assembly process and increase the overall production speed. For electric motor manufacturers who need to produce in large quantities, it can shorten production time and improve efficiency. Electric motor components have high requirements for installation accuracy. If the feeding direction of centrifugal feeders in automation is inaccurate, it will increase the difficulty of assembly and affect the performance of the electric motor. Our centrifugal bowl feeder can ensure that the parts are arranged in the specified direction and stably transported to the next process, reducing installation errors and improving the qualified rate of products.

Traditional vibrating feeders generate large noise during operation. Long-term operation in a high-noise environment will not only affect the comfort of operators, but also increase the noise pollution problem in the factory. Our adjustable speed centrifugal bowl feeder machine uses a smooth rotation method to transport parts, which is quieter during operation, can improve the working environment and reduce noise pollution. In the production process of electric motors, some parts (such as bearings, rotors, stators, etc.) have relatively precise surfaces. If they are subjected to excessive friction or impact during the feeding process, they may cause damage to the parts and affect the quality of centrifugal feeders in automation. Our centrifugal bowl feeder can smoothly rotate and transport, reduce friction between parts, and reduce production losses.

Different types of electric motors require different specifications of parts. Traditional feeding equipment May need to be frequently replaced and adjusted, while our adjustable speed centrifugal bowl feeder machine can adapt to electric motor parts of different sizes and shapes. We can also provide customized services according to your specific needs to improve the applicability of equipment and reduce additional investment. Our centrifugal feeders in automation have a relatively simple structure, stable operation, and convenient maintenance. Regular cleaning and inspection of the equipment can ensure normal operation, and our centrifugal bowl feeder has a longer service life and lower maintenance costs, which can save costs. If you need our products, please contact us.