Product Introduction:

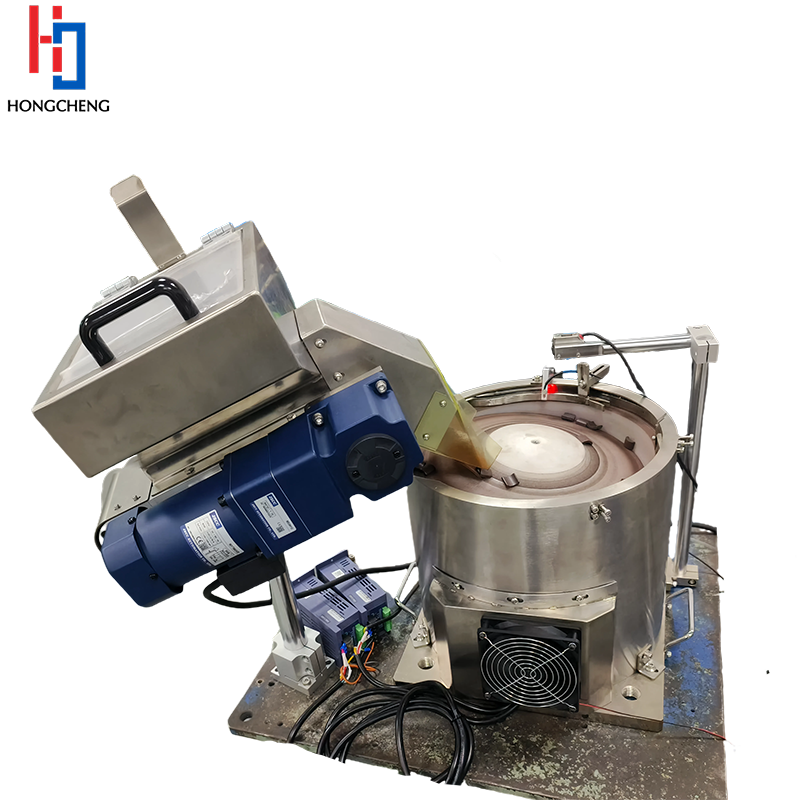

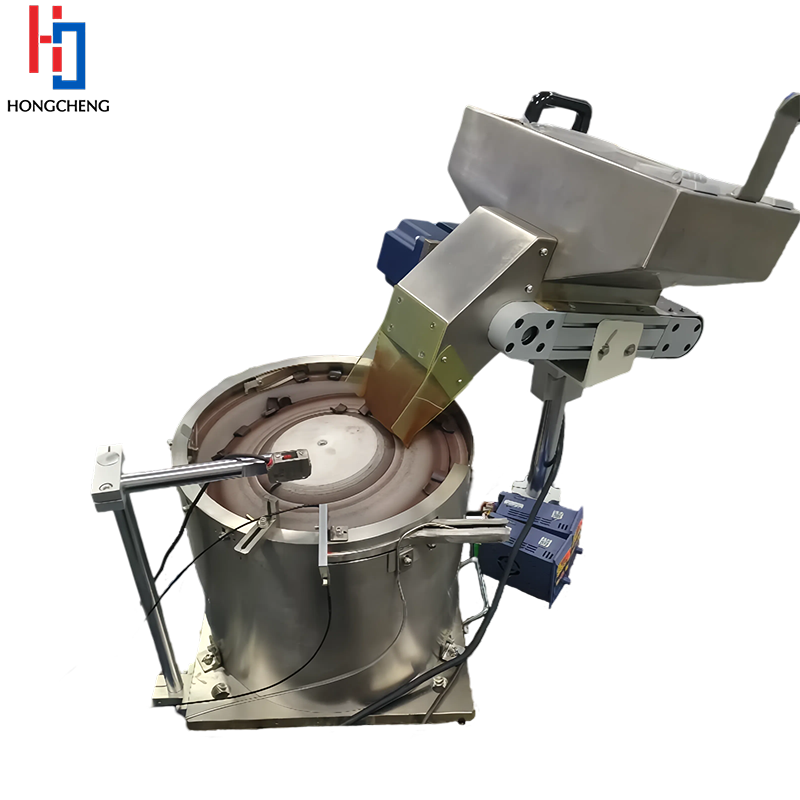

Centrifugal feeders in automation is a feeding device that can be used to convey electric motors efficiently and quickly, and it can also reduce the risk of electric motor damage. It consists of a conical central drive rotor surrounded by a circular bowl wall. It uses rotational force to rotate and separate electric motors, which rotate at high speed and are pulled out of the bowl. Centrifugal feeders in automation are gentle on electric motors due to the low number of cycles and are more suitable for high-speed applications.

Product Advantages:

1.Centrifugal bowl feeder processes electric motors quickly.

2.Adjustable speed centrifugal bowl feeder machine can sort and position components of different sizes and shapes.

3.Centrifugal feeders in automation use simple design, high reliability and low maintenance to make the production cost of electric motors low.

Product Maintenance Guide:

In the daily maintenance of centrifugal bowl feeder, we should regularly clean the feeding channel to avoid dust accumulation and other impurities affecting the feeding accuracy. We should also regularly check the fasteners of adjustable speed centrifugal bowl feeder machine to prevent looseness from affecting the normal operation of the equipment. In order to reduce the wear between parts, we should also regularly oil the moving parts to extend the service life of centrifugal feeders in automation.

Product Application Field:

Our centrifugal bowl feeder can be used in the manufacture of new energy vehicle motors, which can provide precise delivery for the electric motors of new energy vehicles and improve assembly efficiency. Adjustable speed centrifugal bowl feeder machine is also suitable for the production of motors for smart home appliances, such as sweeping robots, electric curtain motors, etc. Our centrifugal feeders in automation are also applicable in the production of motor parts in industries such as aerospace and precision instruments.

FAQ:

Q1: What should I do if the electric motor is unevenly delivered when the centrifugal bowl feeder is running?

A1: Check the feeding speed and vibration frequency of the adjustable speed centrifugal bowl feeder machine, adjust the angle of the equipment, and clean the foreign matter in the channel.

Q2: Is the noise too loud when centrifugal feeders in automation are running?

A2: Check whether the screws of the centrifugal bowl feeder are loose, add lubricating oil, and ensure that the equipment can run stably.

Q3: How to adjust the adjustable speed centrifugal bowl feeder machine to adapt to electric motors of different specifications?

A3: Centrifugal feeders in automation support multiple specifications adjustment, and the conveying channel can be replaced according to the size and shape of the parts to ensure compatibility.

About Us:

Shenzhen Hongcheng Automation Equipment Co., Ltd. focuses on the research and development, sales and service of automatic feeding systems (vibration plates, aluminum plates, flexible platforms, double centrifugal plates, feeders) and non-standard automation equipment. The company's main products cover multiple series such as automatic feeding vibration plates, automatic feeding bins, linear feeders, electronic control systems, vibration platforms, sound insulation covers, vertical vibrators, etc., which are widely used in various types of automated production lines.