Product introduction of rotary feeder for battery parts:

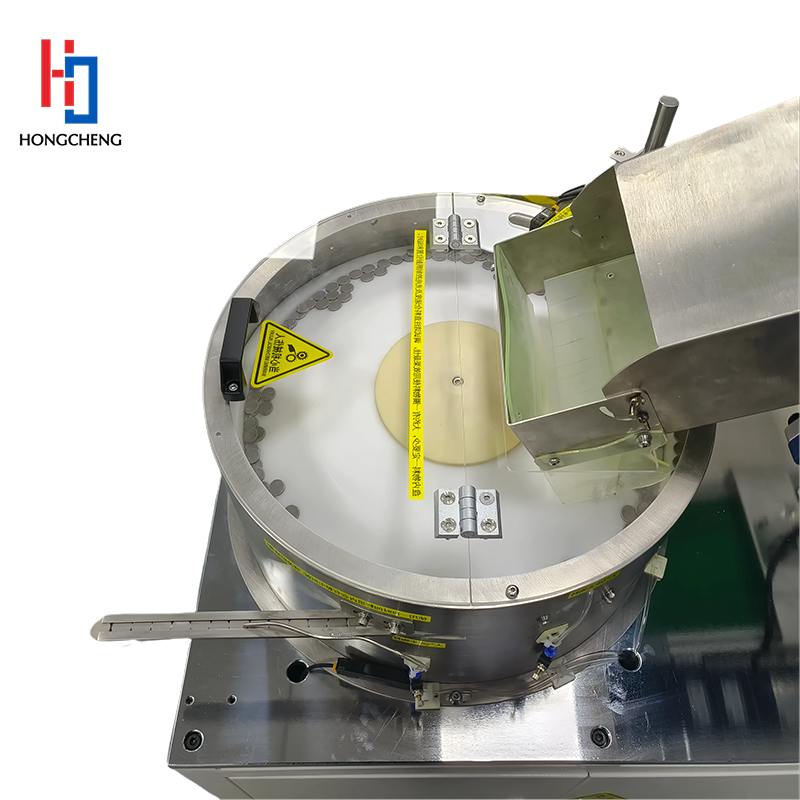

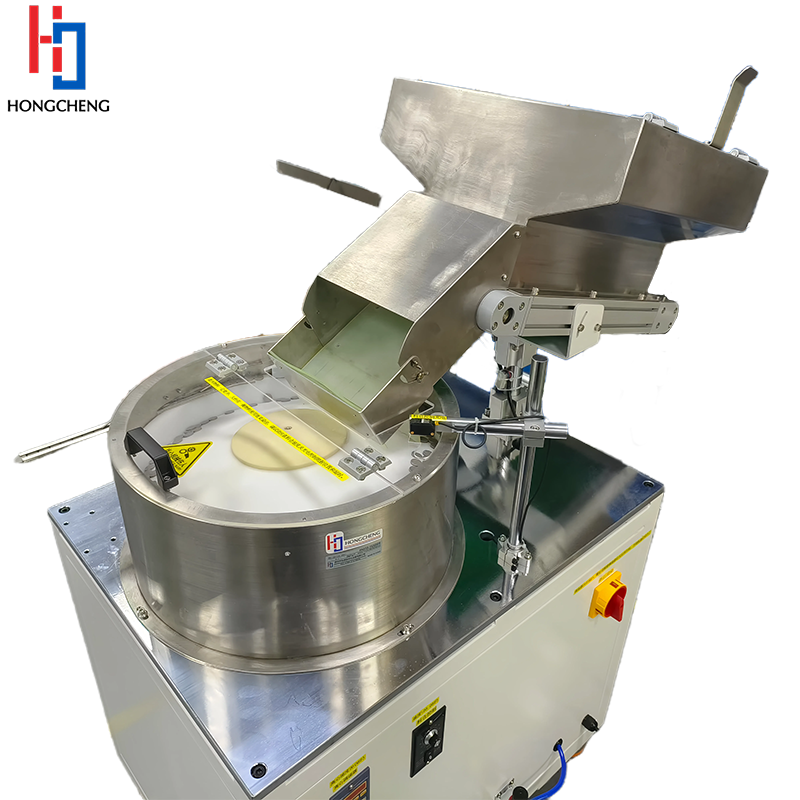

High feed rate centrifugal feeder system is an automated feeding device designed for battery parts production lines. It uses the principle of centrifugal force to accurately sort and convey various battery parts, such as battery shells, diaphragms, positive and negative plates, etc., to ensure that each part enters the production process accurately. Rotary feeder for battery parts not only improves production efficiency, but also automatically adjusts the conveying parameters according to the size and weight of the parts, maintains high consistency, and reduces manual intervention. Rotary feeder for battery parts's durable design and easy maintenance ensure stable operation in high-frequency production environments, helping battery manufacturers improve overall production efficiency and product quality.

Product advantages of high feed rate centrifugal feeder system:

Rotary feeder for battery parts has significant product advantages, especially suitable for the efficient production of battery parts. First, it can quickly and accurately sort and convey battery parts of different shapes and sizes, such as battery shells, diaphragms, positive and negative electrodes, etc., significantly improving the automation level of the production line and reducing manual intervention. Rotary feeder for battery parts uses an intelligent adjustment system to ensure high consistency in material distribution and avoid affecting production quality due to part position or angle deviation. In addition, rotary feeder for battery parts's durability and easy maintenance enable it to maintain stable performance during long-term operation, reduce downtime, reduce maintenance costs, and improve the overall efficiency and reliability of battery production.

Product applications of high feed rate centrifugal feeder system:

Battery shell: Suitable for battery shells of various sizes and shapes.

Separator: Material used to separate the positive and negative electrodes of the battery, usually thin and light.

Positive and negative electrodes: Includes the positive and negative electrodes of the battery, usually in a wound or flat form.

Battery cover and cover plate: The upper cover or sealing cover plate used for battery packaging.

Battery terminal: The terminal component used to connect the battery circuit.

By adjusting the speed and angle of the feeder, high feed rate centrifugal feeder system can accurately handle battery parts of different shapes and sizes to ensure the smooth progress of the automated production process.

Service and guarantee of centrifugal bowl feeders:

According to the specific needs of battery parts, we provide customized centrifugal bowl feeders to ensure that the equipment is perfectly adapted to your production line and improve work efficiency. We also provide professional centrifugal bowl feeders installation and commissioning services to ensure that centrifugal bowl feeders can be put into use quickly and accurately, helping you to efficiently complete the sorting and transportation tasks of battery parts. Our after-sales service department provides you with high feed rate centrifugal feeder system operation training to ensure that your staff can master the use of the equipment proficiently, and at the same time provide long-term technical support to answer any questions encountered during use at any time.

About us:

Shenzhen Hongcheng Automation Equipment Co., Ltd. is committed to the innovation and development of automation equipment. Our main products include bowl feeders, centrifugal feeders, linear feeders, etc. Our products cover multiple industries such as light industry, electronic precision, medicine and food packaging. The company has passed ISO and CE certifications, and always adheres to the principle of "quality first, innovation driven" to provide customers with high-quality automation solutions. Our professional team not only provides product design, but also provides customers with full technical support and after-sales service to help customers improve production efficiency.