On the production line of coffee bags, the sharp edges of the packaging bags may cause wear and tear on traditional feeding equipment. However, the special material and protective design of the centrifugal feeder for orienting coffee pods we use have been able to solve this problem and ensure the long-term stable operation of the centrifugal feeder for orienting coffee pods.

It is possible that the continuous friction between the packaging bag and the conveying track or the collision during high-speed operation will cause the edge of the coffee bag to wear and tear the equipment. Through long-term observation, our engineering team found that the conveyor track of ordinary materials will show obvious wear marks after three months of use. For this problem, our centrifugal feeder for orienting coffee pods uses protective technology and uses wear-resistant coatings on key contact areas, which improves wear resistance a lot.

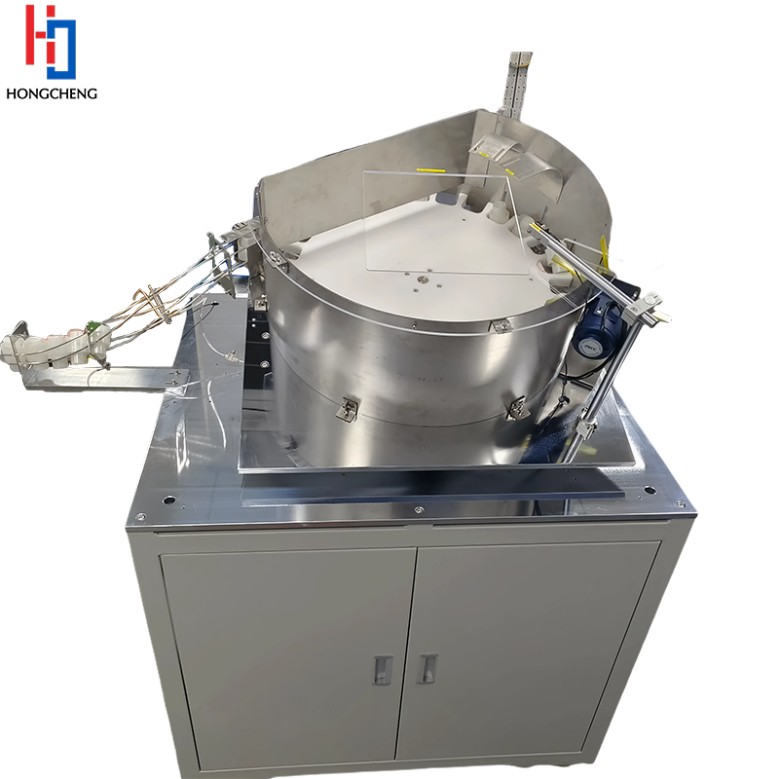

Our centrifugal feeder for orienting coffee pods, designed specifically for coffee bags, uses multiple protective measures. The conveyor track is designed to be easy to disassemble, and can be replaced separately in areas that are easy to wear, reducing maintenance costs. The guide device uses composite materials, which can be transported smoothly and absorb the impact force. Our centrifugal feeder for orienting coffee pods is also equipped with a monitoring function, which will automatically alarm and prompt maintenance when abnormal wear is detected, which will not affect the production progress.

We use innovative design concepts, use super hard materials to resist wear on the contact surface, and use elastic materials to absorb vibration on the support parts. It can also adjust the conveying parameters according to the sharpness of the edge of the coffee bag. One of our coffee brand customers reported after using our performance feeders centrifugal feeder that after one year of continuous operation, the key components of the performance feeders centrifugal feeder wore out very little.

We can provide customized services for each customer. The sharpness and shape of different coffee bags are different, some have sharp edges, while others have obvious edges and corners. We will adjust the contact part of the performance feeders centrifugal feeder according to the needs provided by the customer. For example, for coffee bags with obvious edges and corners, the curvature on the inside of the track will be increased, so that the contact area at the edges and corners will be larger, and local wear will be reduced. For particularly sharp coffee bags, special materials that are more wear-resistant will be selected to extend the replacement cycle of performance feeders centrifugal feeder.

Our factory specializes in wear-resistant testing of equipment. Each equipment must undergo strict testing before leaving the factory to ensure that the protection performance meets the standard. Our technical team provides selection suggestions or helps you solve other problems. Our performance feeders centrifugal feeder pays attention to conveying efficiency, and pays more attention to the durability and economy of equipment. If you are interested in our performance feeders centrifugal feeder, please feel free to contact us.