In the production workshop of the electronics factory, on the disc of the aluminum bowl feeder, hundreds of electronic components are arranged in an orderly manner with vibration. But not all parts are suitable for this feeding method. Understanding what kind of parts are suitable for Cast Aluminum Vibratory Feeder Bowl can improve our production efficiency.

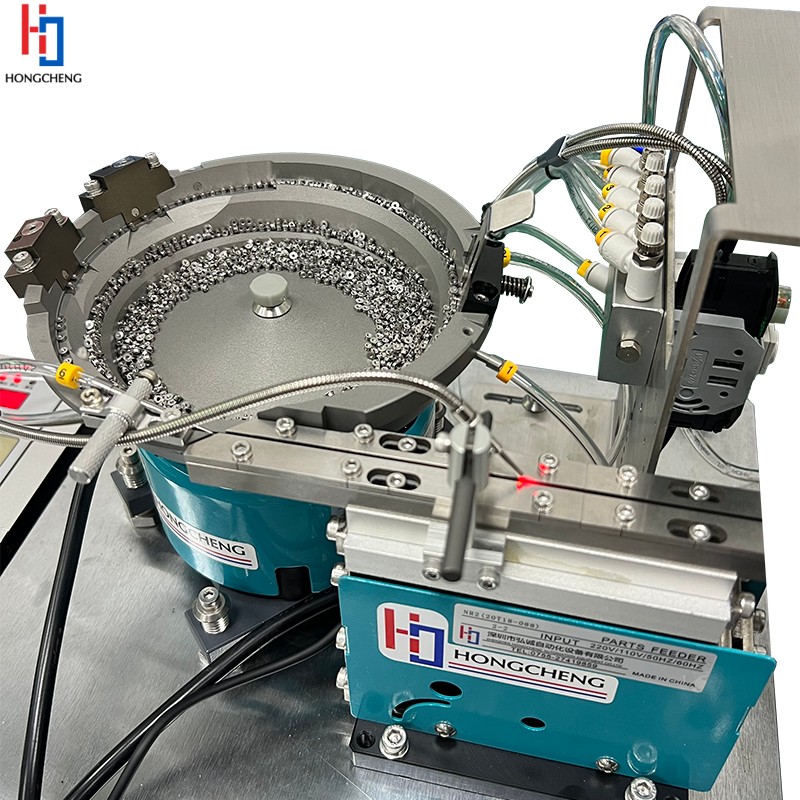

Small metal parts are more suitable for aluminum bowl feeder. Standard parts such as screws, nuts, and gaskets are transported on the disc surface, which is very easy to arrange neatly. Especially hardware with a diameter between 2-10 mm, the weight is moderate, will not be shaken off, and will not be too heavy to transport. Auto parts factories use Cast Aluminum Vibratory Feeder Bowl to process spark plug gaskets, which can sort tens of thousands of them in an hour.

Electronic components also often appear on the aluminum bowl feeder disk. Electronic components such as resistors and capacitors are transported smoothly on the aluminum disc. The natural anti-static properties of aluminum allow precision electronic components to not be damaged during transportation. SMT workshops like to use aluminum bowl feeder to feed the placement machine, which is fast and does not damage the parts. Some factories will also install special coatings on the disk surface so that the chips can be transported safely.

The transportation of plastic parts on the aluminum bowl feeder is also very common. Bottle caps, buttons, and toy parts are transported smoothly on the aluminum plate. Compared with metal discs, aluminum discs have a softer surface and will not scratch the plastic surface. Medical device factories can use Cast Aluminum Vibratory Feeder Bowl to sort syringe pistons without scratches. Adjust the appropriate vibration frequency, and even special-shaped plastic parts can be transported in an orderly manner.

Metal stamping parts of various shapes, such as springs, terminals, contacts, etc., although their shapes are irregular, aluminum bowl feeder can also be transported smoothly through customized track design. Auto parts factories use Cast Aluminum Vibratory Feeder Bowl to process metal parts of seat belt buckles with complex shapes, and the customized track groove design allows each part to be transported accurately.

Shenzhen Hongcheng Automation Equipment Co., Ltd. It is a high-tech enterprise focusing on the research and development, production and sales of non-standard automation equipment, and is committed to providing customers with efficient, reliable and customized automation solutions. The company's main products are various types of feed pallets, and it has accumulated rich experience in R&D, sales and service in related fields. Adhere to customer needs as the core, continue to innovate, and improve product quality and service standards.