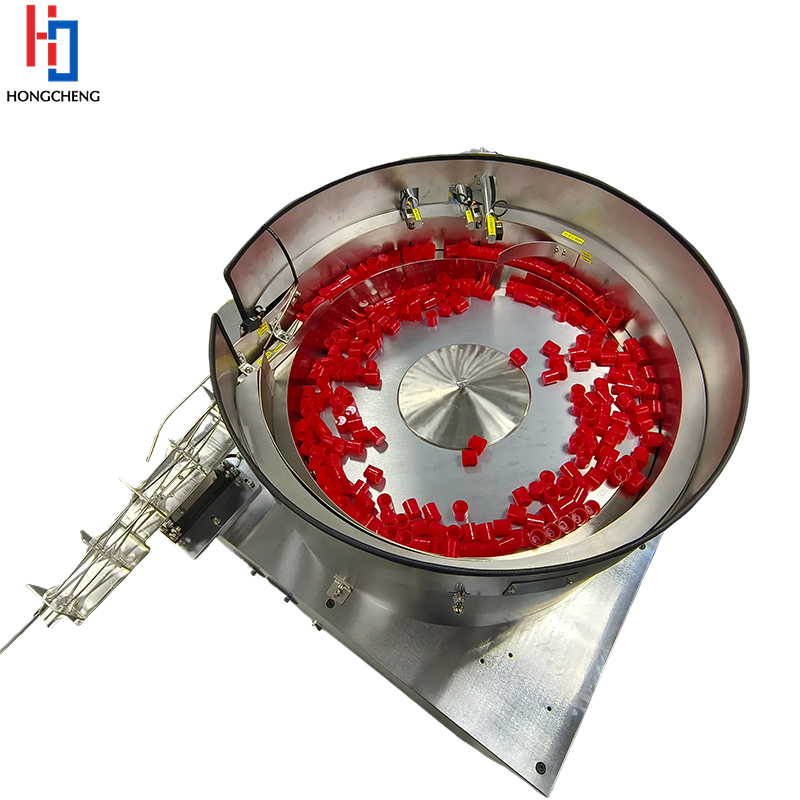

In the production workshop of electronic components, the centrifugal feeder is in operation. The miniature capacitors with a diameter of 1 mm are evenly distributed on the rotating disc, and they run in an orderly manner to the outlet track under the action of centrifugal force. Centrifugal feeder will appear in many industries such as electronic manufacturing, medicine, and food. Centrifugal feeder is a key equipment on automated production lines.

The electronics manufacturing industry is the place where the centrifugal feeder has the most presence. On the SMT patch production line, it can separate and sort miniature components such as resistors and capacitors for stable feeding. Compared with traditional vibration discs, the centrifugal design is more suitable for handling small and light precision components, which can reduce part stagnation and surface wear. The semiconductor packaging workshop also uses a centrifugal feeder, and the chips are separated on a centrifugal disc without worrying about electrostatic damage.

The pharmaceutical industry also uses the centrifugal feeder feeding method. Capsules and tablets are gently rolled on the centrifuge disc, and can be accurately counted through a special device. The feeder made of sterile grade stainless steel is very suitable for production environments with strict sanitary conditions. In the eye drops production line, the centrifugal feeder can sort the miniature drippers, and the error is very small.

Centrifugal feeder is also used in the field of food packaging. Our sanitary centrifugal feeder meets the hygiene standards of food production and adopts a silent design to ensure that the noise of the equipment is low during operation and will not interfere with the production environment. Candies and nuts are transported in food-grade centrifugal trays, and accurately enter the packaging bags after sorting. Gently separating the food can make the crispy food undamaged, and the processing capacity can reach 3,000 servings per hour, which is very efficient. Some high-end chocolate factories have even customized thermostatic feeders to ensure that the products remain in good condition during the dispensing process.

Shenzhen Hongcheng Automation Equipment Co., Ltd. The main products include: vibrating bowl feeder, centrifugal feeder, aluminum bowl feeder and other products. The feeders we produce can provide customized services to meet customer needs. We also use advanced equipment, perfect design, excellent production and excellent quality to design difficult and high-quality feeder systems and non-standard equipment to solve your many automation problems.

Choosing us, you will have a reliable logistics system to ensure on-time delivery of products, a professional technical team, provide perfect after-sales service, and advanced production equipment to ensure efficient and stable production capacity. And we will continue to invest in research and development to make our products technologically advanced and meet the latest industry needs. If you have any questions, please feel free to contact us!