In a modern production workshop, the vibratory bowl feeder is inseparable. This simple device is not easy to operate. Before pressing the start button, we must first check whether the tray is firmly installed and whether the vibration spring is loose. After the power is turned on, the vibration frequency is slowly adjusted through the knob on the control panel to observe the movement of the material until the parts form a stable flow on the track.

Before operating the vibratory bowl feeder, carefully check whether there are any remaining problems from the last time you used the machine. Check and exclude whether there are materials and other debris between the body and the spring and bracket that affect the movement of the body. Carefully check whether all parts are completely fastened and whether the lubricating oil in the exciter is higher than the oil standard. Check whether the transmission belt is in good condition; if it is found to be damaged, it should be replaced in time; if there is oil, wipe it with a rag.

After the inspection, if the machine and the transmission part are in normal condition, then the vibratory bowl feeder can be started. After starting, if an abnormal phenomenon is found, it should be stopped immediately. After checking the abnormal situation, it can be started again.

After the vibratory bowl feeder stabilizes the vibration, the material can be put into operation. The added materials must meet the requirements of the load. Shutdown should be in accordance with the requirements, and it is forbidden to stop when there are still materials on the machine, or to continue to add materials during and after shutdown.

There are several key points in the operation process that need our attention. The amount of materials to be delivered should be moderate. Too little will affect the feeding efficiency, and too much may lead to the accumulation of parts. Parts of different shapes need to adjust different vibration parameters, and the settings of flat parts and long strip parts are different. We must regularly check the track wear of the vibrating bowl feeder. Excessive wear will affect the accuracy of the orientation of the parts. During shutdown, the vibration should be turned off first, and then the power supply should be cut off, which can extend the service life of the equipment.

Daily maintenance can keep the vibratory bowl feeder in good condition. Clean up the inside of the tray once a week to clean up accumulated debris and oil stains. Check the fastening of the electromagnetic coil every month. Loose coils will affect the vibration effect.

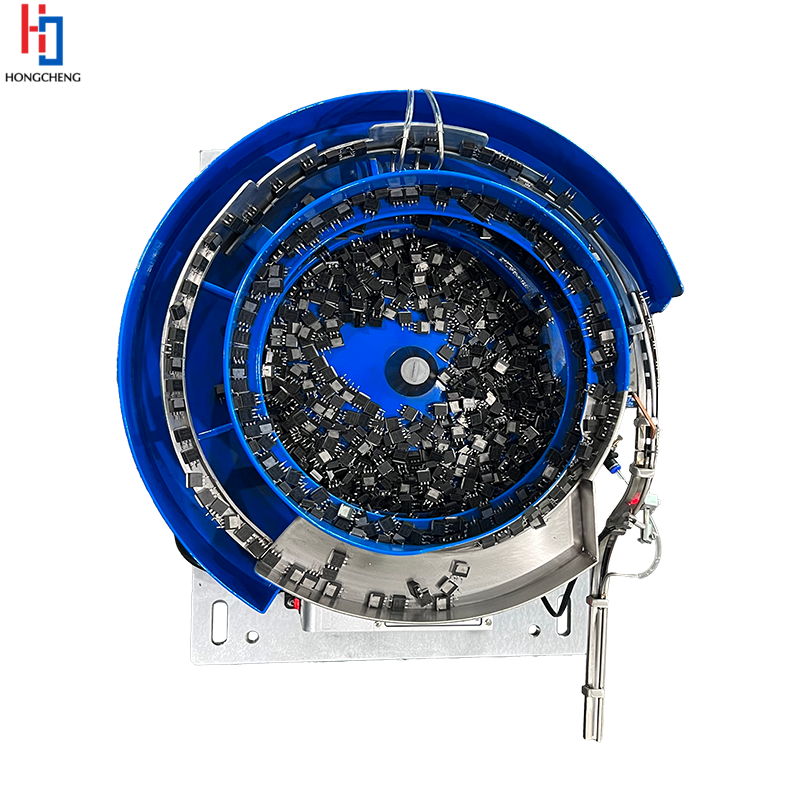

Shenzhen Hongcheng Automation Equipment Co., Ltd. It is a manufacturer engaged in the research and development, sales and service of non-standard automation equipment for feeder systems. The company's main products include: vibrating bowl feeder, centrifugal feeder, aluminum bowl feeder and other products. And we have a perfect after-sales service system and excellent after-sales service personnel. If you are interested in our feeder, please feel free to contact us!