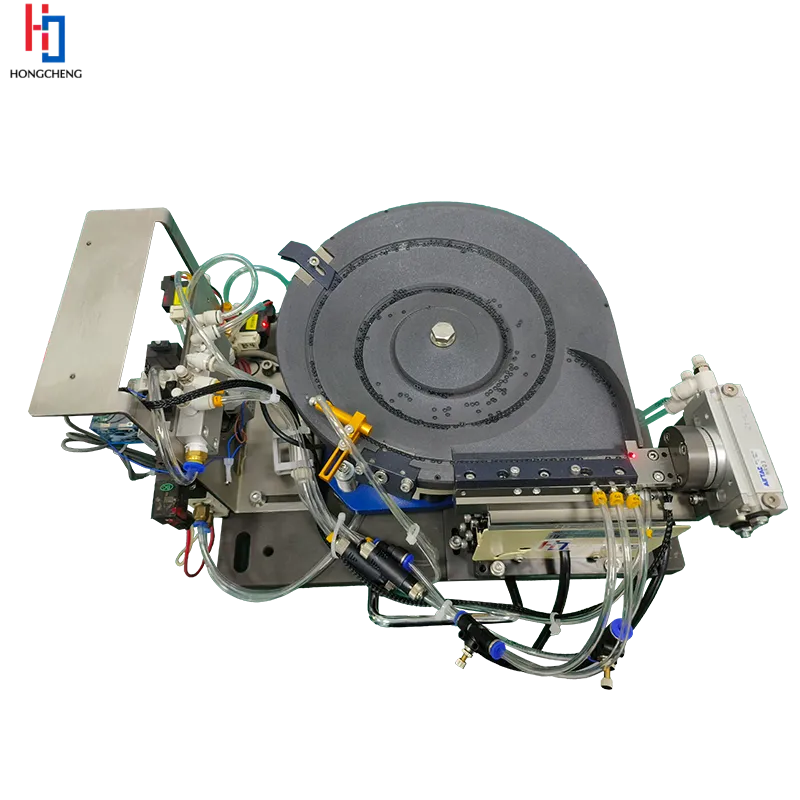

In automated production lines, cast aluminum vibrating feeder bowl is very light in weight and corrosion resistance is widely welcomed. This equipment is widely used in electronic manufacturing, auto parts, medical equipment and other industries. If you want the cast aluminum vibratory feeder bowl to work properly, the correct installation and use method is very important. The correct installation and use of equipment can not only ensure the stability of the feeding, but also extend the service life of the equipment. This article will mainly introduce how our cast aluminum vibratory feeder bowl is installed and used.

How is the cast aluminum vibratory feeder bowl installed?

1. When installing, place the cast aluminum vibrating feeder bowl on a flat and sturdy work surface, and fix the base with bolts. Adjust the horizontal angle so that the equipment will not vibrate and shift.

2. Before connecting the power supply, we have to check whether the voltage matches. Under normal circumstances, the nameplate of the cast aluminum vibrating feeder bowl will indicate the operating voltage and power requirements.

3. When using it, use the control panel to adjust the vibration frequency and amplitude, and observe the flow of materials until we achieve the conveying effect we want. If an abnormality is found, stop immediately for inspection.

In use, the operator can adjust the vibration frequency and amplitude through the rotation button on the control panel. During the mediation process, you need to patiently observe the flow state of the materials. If you see the materials in a stable and orderly arrangement on the track of the cast aluminum vibrating feeder bowl, you can do it. The vibration parameters required for parts of different materials and shapes are different, which requires the experience of the operator. It should be noted that the debugging of the equipment can not be successful in one go, and it may take several patient adjustments to achieve the effect we want.

Daily maintenance can ensure the long-term stable operation of cast aluminum vibrating feeder bowl. The inside of the bowl should be cleaned once a week to clean up the debris and oil inside. Check once a month whether the connection part is firm. For equipment that transports special materials, such as electronic components that require anti-static treatment, we must regularly check whether the anti-static coating is intact. If the equipment needs to be disabled for a long time, it needs to be thoroughly cleaned first, then the power is cut off and a dust cover is put on. Note that lubricating oil should be added to the bearings in the feeder every 2 months, and once a month for high summer temperatures.

Shenzhen Hongcheng Automation Equipment Co., Ltd. The production of cast aluminum vibrating feeder bowl can help you solve many automation problems. The company takes customers as the center, and the equipment provides personalized customization services. The logistics is very fast and the goods can be delivered on time. And we have high-quality after-sales service. If you are interested in our cast aluminum vibrating feeder bowl, please feel free to contact us.