From the perspective of mass production, plastic vibratory bowl feeder is indeed more advantageous in terms of initial cost. It has fast processing speed and low material cost, which is very suitable for the rapid turnover of some light and small materials. However, if the stability, durability and maintenance frequency of long-term use are considered, aluminum vibratory bowl feeder is more cost-effective. Many customers choose plastic vibratory bowl feeder in the early stage for budget considerations, but after using it for a period of time, they find that frequent replacement and long debugging time make the comprehensive cost not low. In the future, they tend to choose aluminum bowl feeder.

Plastic vibratory bowl feeder is suitable for standardized materials, such as plastic parts and small light metal accessories. It has no problem with the scope of application, especially in occasions where the feeding accuracy is not so high. HONGCHENG's plastic vibratory bowl feeder uses high-strength engineering plastics, mold injection molding, precise size and not easy to crack. It can also be designed with anti-static and anti-slip according to customer requirements, and the color can also be customized, which is both practical and beautiful. The advantages of plastic vibratory bowl feeder are light, fast and convenient, but its service life is indeed relatively short. On the high-frequency running assembly line, it will wear faster than aluminum vibratory bowl feeder.

Aluminum bowl feeder is like an "endurance player", with a stronger structure and higher pressure bearing capacity. It is not afraid of complex environments such as high temperature, humidity, and oil pollution. It is particularly suitable for continuous work of metal parts, special-shaped parts, and heavy-loaded materials. Many customers used plastic bowl feeder, which started to have problems after half a year of operation. After changing to aluminum bowl feeder, they did not need much maintenance for a year, and the stability was visible to the naked eye. Although the unit price is slightly higher, it lasts longer and saves a lot of trouble. From the perspective of cost performance, it is very suitable for long-term use.

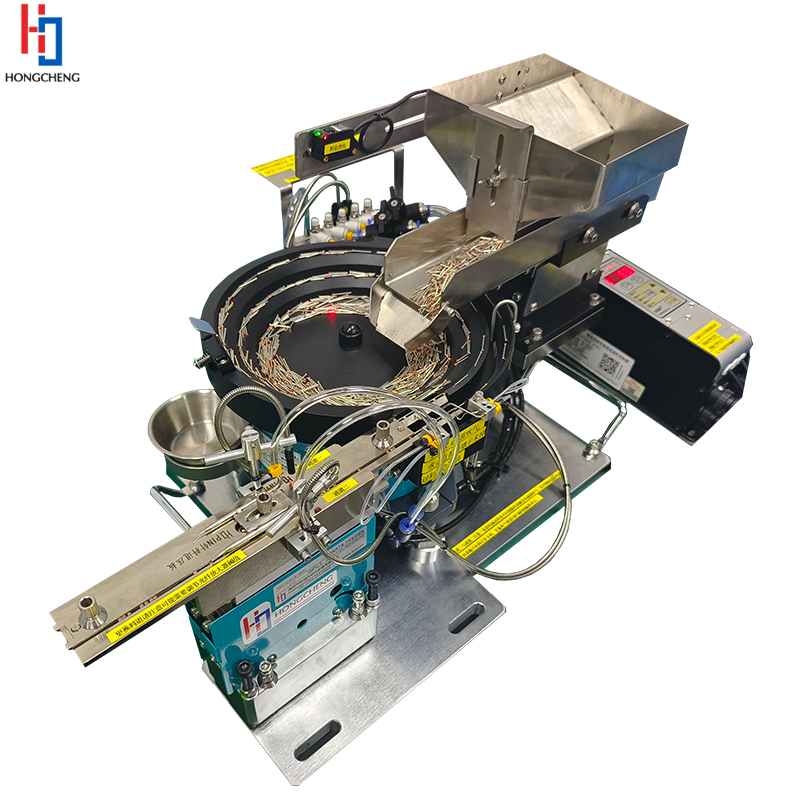

HONGCHENG has complete production lines for both series. We have multiple sets of aluminum bowl feeder injection molds that can adapt to a variety of standard disc diameters and depths, with fast delivery speed, suitable for projects with high time requirements. For the aluminum bowl part, we are equipped with five-axis CNC equipment. Each bowl is finely carved, and the groove width and bevel can be customized according to the characteristics of the material. Whether you are a light or heavy part, round, square, or special-shaped, we can customize production.

Some customers are worried about making the wrong choice. We will first recommend test samples to help customers find the most suitable bowl structure. Some customers also use plastic bowls to start trial production, and then upgrade to aluminum bowls to cope with higher-strength production lines after the process matures. This method not only saves initial investment, but also lays a good foundation for later mass production.

Whether you prefer the lightweight and flexible vibratory bowl feeder or the robust and durable aluminum bowl feeder, we can provide a full range of support and services. Welcome to bring materials for testing, we can help you compare and choose, so that your production line runs smoother, faster, and more cost-effective. If you have special needs, you can also talk to us about customized solutions, you may find that we are a trustworthy long-term partner!