Compared with aluminum bowl feeder and pneumatic feeder, which one has better performance? There is actually no absolute answer to this question, but if the product you need is stable operation, compact structure, easy debugging, and wide adaptability, then aluminum vibratory bowl feeder will be more suitable. It has obvious advantages in precision feeding, high-speed operation, and long-term stability, and is especially suitable for industries with high positioning accuracy requirements such as electronic components, hardware accessories, and medical consumables.

The characteristics of pneumatic feeders are simple structure and direct drive mode, which are very suitable for some stations with strong rhythm and repeated feeding actions. Its advantages are large impact force and fast rhythm. However, it has high requirements for air supply stability, the machine is easily affected by air pressure fluctuations, and it is often necessary to maintain components such as cylinders and valves. The aluminum vibratory bowl feeder belongs to the electromagnetic vibration structure, which runs more smoothly, continuous feeding will be more accurate, and it is not easy to cause problems such as jamming or slipping. Especially when running for a long time, aluminum bowl feeder has better stability and energy saving performance, and lower maintenance costs in the later stage.

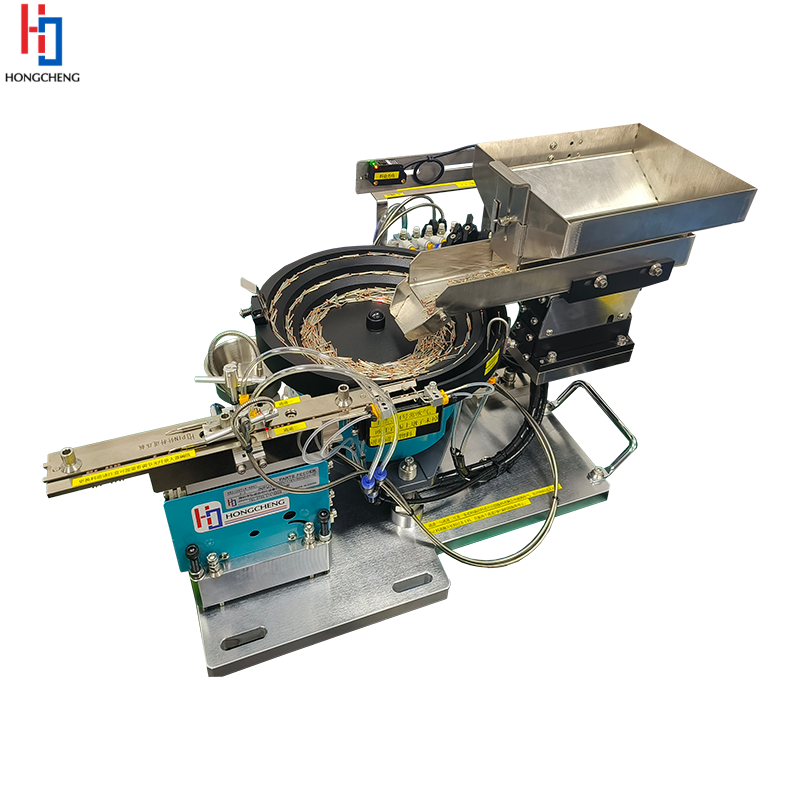

Hongcheng Factory specializes in the production of aluminum vibratory bowl feeder and has many years of production and design experience. The aluminum bowl feeder we produce is very mature in structure and performance. Each set of equipment can be customized according to the shape, size and weight of the customer's product to customize the bowl angle, slot width and channel layout to ensure that the material runs smoothly in the bowl without spinning or flipping. Many customers who used pneumatic structures before switched to the aluminum vibratory bowl feeder we provide. Customer feedback generally said that it was "much less troublesome", the running noise was much smaller, and the efficiency was higher.

We have a professional design and after-sales team that can respond to customer needs quickly. From drawing design, sample testing, to machine testing, delivery and installation, we have a standard process for each step. Some customers are worried about choosing the wrong model, so we will make free samples and test materials; some customers have limited on-site space, so we provide compact design solutions; some customers need special packaging for export, and we can also support reinforced wooden boxes, moisture-proof treatment, etc.

If you are also considering changing equipment, or are hesitating about which type of feeding system to use, why not try our aluminum bowl feeder. We believe that the stability of the product, the thoughtful service, and the flexible design will always satisfy you. If you have any questions, please feel free to talk to us or come to our factory to have a look. You may find a suitable solution in our factory.