When purchasing Vibratory Bowl Feeder, many customers will ask a seemingly simple but important question: "Does this Vibratory Bowl Feeder meet the power supply standards of our country?" In China, the common power supply configuration is generally 220V, 50Hz single-phase AC, which can be easily connected in most factory workshops. For equipment operators, it is very convenient to start the machine by simply plugging the plug into an ordinary industrial power socket.

But if the customer's factory is overseas, such as the United States, Japan, Australia and other countries, the voltage and frequency are different. For example, the United States is 110V/60Hz, Japan may be 100V, and Europe is generally 230V/50Hz. At this time, we will design a power system and plug interface that adapts to the local power grid according to the usage standards of the customer's local country to ensure that the Vibratory Bowl Feeder can operate safely and stably, and avoid damage or misoperation caused by voltage mismatch.

In addition to voltage and frequency, we can also design Vibratory Bowl Feeder with functional modules such as power switch, frequency conversion control, voltage stabilization module, etc. according to different needs of customers. We can also provide customers with electronic control units with international certifications such as CE and UL to help customers pass local use audits smoothly, especially in markets such as Europe and North America where equipment certification requirements are high. This support is very important.

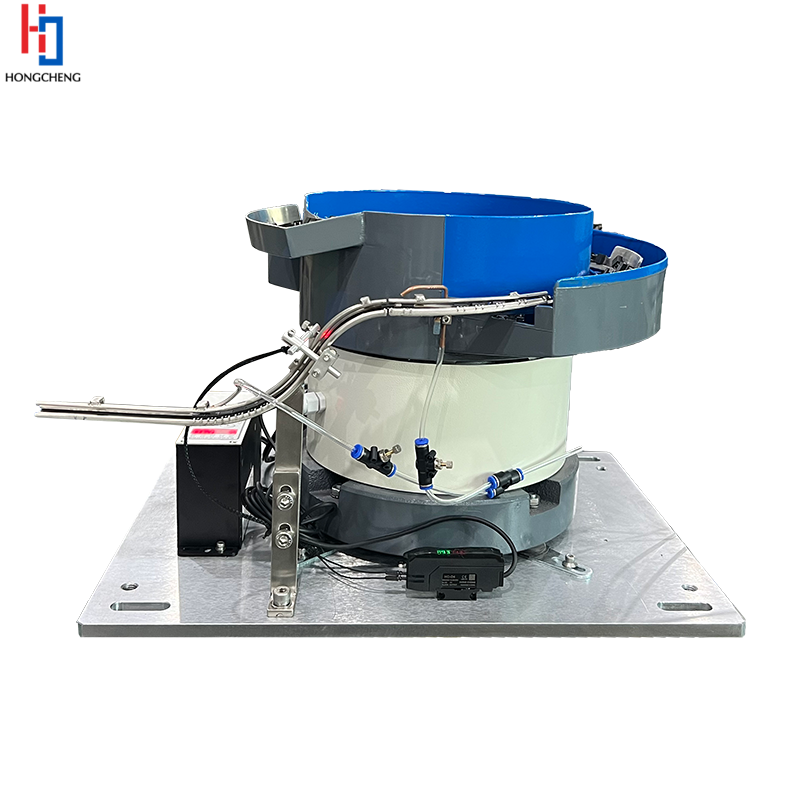

After connecting to the power supply, just turn on the power switch of Vibratory Bowl Feeder and adjust the vibration intensity button or knob to adjust the feeding rhythm of Vibratory Bowl Feeder according to the weight and shape of the parts. It is recommended to cut off the power supply in time after each use of Automatic Vibratory Bowl Feeders, and do a good job of cleaning and maintenance to extend the service life of the equipment.

We know that the shape, size and process flow of each customer's parts are different, which is also our advantage in non-standard customization. We can design different track structures, hopper sizes, discharging directions, electronic control systems, etc. according to the feeding samples provided by customers to ensure that Automatic Vibratory Bowl Feeders can perfectly adapt to the production line. At the same time, our engineering team has many years of export experience, can quickly identify the power consumption environment in different countries, and provide mature overseas power consumption solutions.

Your products are special-shaped parts and precision components, and you can't find a suitable feeding solution? Feel free to contact us. We can not only design the right track for you, but also match the right power supply for your device. We will match the standard of the country you want to ship to! If you have any ideas, please send us drawings and samples, and we will customize your own Automatic Vibratory Bowl Feeders for you.