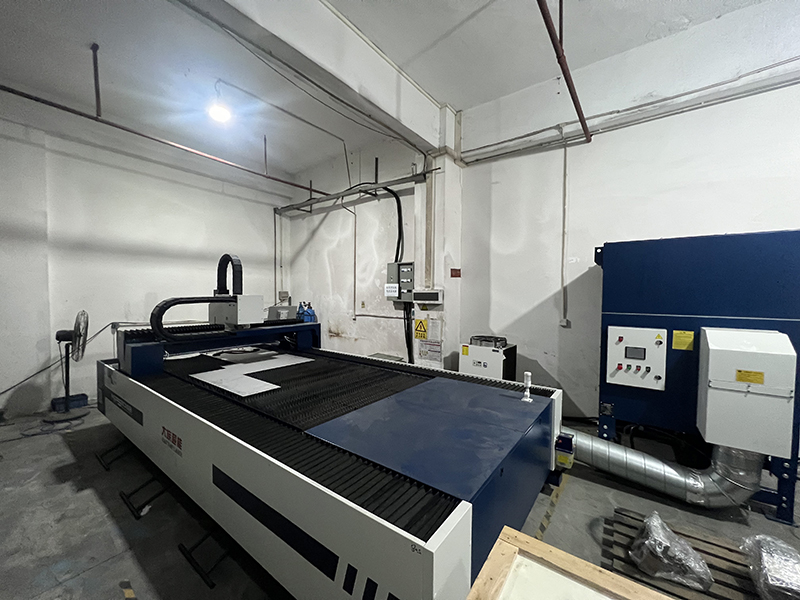

In order to better serve customers, improve product quality and processing efficiency, the Hongcheng factory has recently introduced a batch of advanced laser cutting equipment and machining production lines, comprehensively upgraded the automation level, and provided stronger support for non-standard customized projects.

We are a professional manufacturer focusing on Vibratory Bowl Feeder and automated feeding equipment, with many years of experience, and can carry out non-standard customization. Whether it is a standard structure or a particularly complex special-shaped part, we can provide customers with highly adaptable solutions.

The latest laser cutting equipment introduced by our factory this time has the advantages of high precision, fast speed, and smooth cutting surface, which is particularly suitable for processing various types of metal sheets and structural parts. In conjunction with our original CNC bending, welding, turning and milling processing centers, the overall processing accuracy and production efficiency have been further improved. The use of new equipment enables us to complete the manufacturing of core components such as Vibratory Bowl Feeder fuselage, guide rails, and vibration plates more quickly, from drawings to physical objects, with shorter cycles and more stable quality.

In terms of non-standard customization, we have a mature technical team and flexible project processes. Whether customers need to adapt buttons, screws, toy parts, electronic accessories, or other materials with special shapes, we can design accurately according to samples and parameters. Some time ago, we customized a batch of bowl feeders for an Egyptian customer, which supports the compatible use of 9 different buttons, and the customer was very satisfied.

Our AVibratory Bowl Feeder has a compact structure, stable operation, and strong adaptability. It is widely used in electronics, hardware, toys, medicine, light industry and other industries. It supports stand-alone operation and can also be integrated into automated production lines. For customers with high requirements for accuracy, speed, and compatibility, we provide customized services in various models and structural forms, including key modules such as vibration plates, automatic arrangement tracks, and controller adjustment.

The factory has modern production workshops, complete processing equipment, and experienced assembly and quality inspection teams, with the ability to produce thousands of devices annually. All Vibratory Bowl Feeders undergo multiple rounds of testing before leaving the factory to ensure that stable and reliable products are delivered to customers.

Customers from all industries are welcome to discuss cooperation with us, and we sincerely invite you to visit our factory to learn about our production strength and service capabilities on site. Want to customize Vibratory Bowl Feeder? Welcome to chat with us.