In the purchase of automation equipment, many customers will ask a key question: "Can you do non-standard customization?" The answer is yes, we can not only do it, but also have a dedicated design team to do it. Many customers' products have different shapes, sizes, and special materials. Conventional standard multipurpose vibratory feeder bowl cannot meet the needs at all. At this time, we need our professional non-standard customization service to solve the problem.

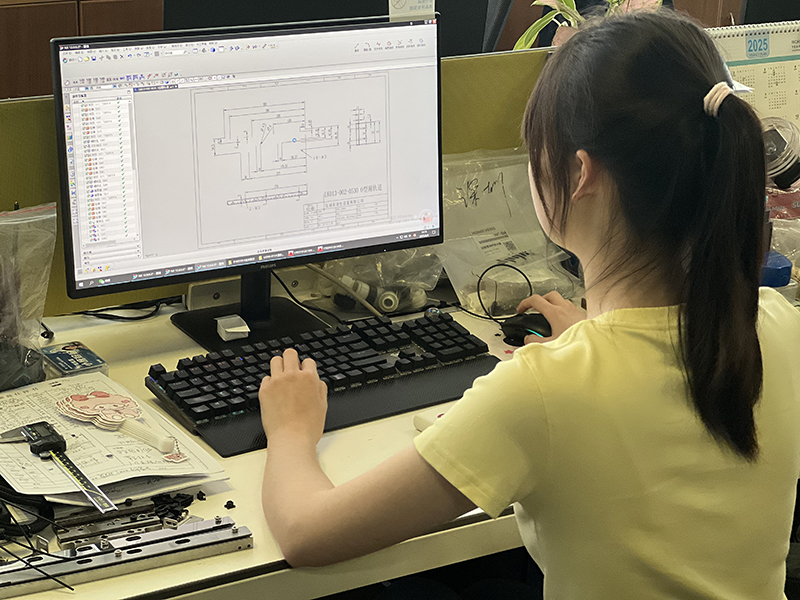

HONGCHENG has an experienced design and R&D team that is responsible for the development of non-standard bowl feeder vibrating. Whether it is structural design, electrical control, or assembly and debugging, we can complete it independently. As long as the customer can provide product drawings or physical samples, our engineers can quickly evaluate, model, and propose matching feeding structure solutions. Sometimes, the customer only provides a product bag, and we can also calculate the most suitable feeding structure through measurement, disassembly, testing, etc. This flexibility and professionalism is one of the reasons why many automation integrators and multipurpose vibratory feeder bowl users choose us.

Our multipurpose vibratory feeder bowl has the characteristics of stable operation, low noise, easy adjustment, and strong compatibility. For different types of products, we will design different chassis diameters, material channel angles, discharging methods, and even matching intelligent modules such as visual inspection and servo control to achieve precise positioning and accurate material distribution. We also pay special attention to details, such as anti-scratch, anti-stuck, anti-static treatment, etc., which can be customized according to industry needs. We have accumulated a lot of mature experience in the cleanliness requirements of the pharmaceutical industry, the precision requirements of the electronics industry, and the durability requirements of the hardware industry.

In terms of production, our factory is equipped with advanced manufacturing equipment such as high-precision CNC processing equipment, laser cutting machines, automatic welding robots, etc. to ensure the accuracy and consistency of each part processing. All bowl feeder vibrating has been tested and run for a long time before leaving the factory to ensure plug-and-play at the customer's site. We can even provide customers with a complete technical data package, including drawings, circuits, programs, etc., to facilitate customers' subsequent maintenance or multi-machine replication.

So, if you happen to have special-shaped parts that need bowl feeder vibrating, you might as well contact us to talk. Whether it is screws, springs, electrodes, hardware accessories, or magical structures you have never seen before, we are willing to accept challenges. We are not just doing bowl feeder vibrating, but also helping customers turn "ideas" into "productivity." Welcome to bring your problems and test the strength of our team!