What kind of materials can vibratory bowl feeder feed? This question is of concern to many friends when purchasing automation equipment. In fact, the scope of application of bowl feeders is very wide. Whether it is metal parts, plastic accessories, rubber products, or electronic components, medical accessories, small screws and small springs, they can be automatically arranged and directed by vibratory bowl feeder. As long as the workpiece is regular in shape, small in size and light in weight, it can almost handle it. And it can also be used in conjunction with processes such as visual inspection and robot grasping to improve the efficiency of the entire production line.

In the hardware industry, standard parts such as screws, nuts, and washers are very suitable for sorting with vibratory plate bowl feeder; in the electronics industry, small capacitors, small resistors, and connecting terminals are also suitable for bowl feeding; in the medical industry, small needles, test tube caps and other plastic parts are often used for automatic feeding. Not only that, many toy factories, auto parts factories, and daily necessities manufacturers also use vibratory bowl feeder. Its biggest advantage is that it can neatly deliver a bunch of messy small parts to the production line in a short time.

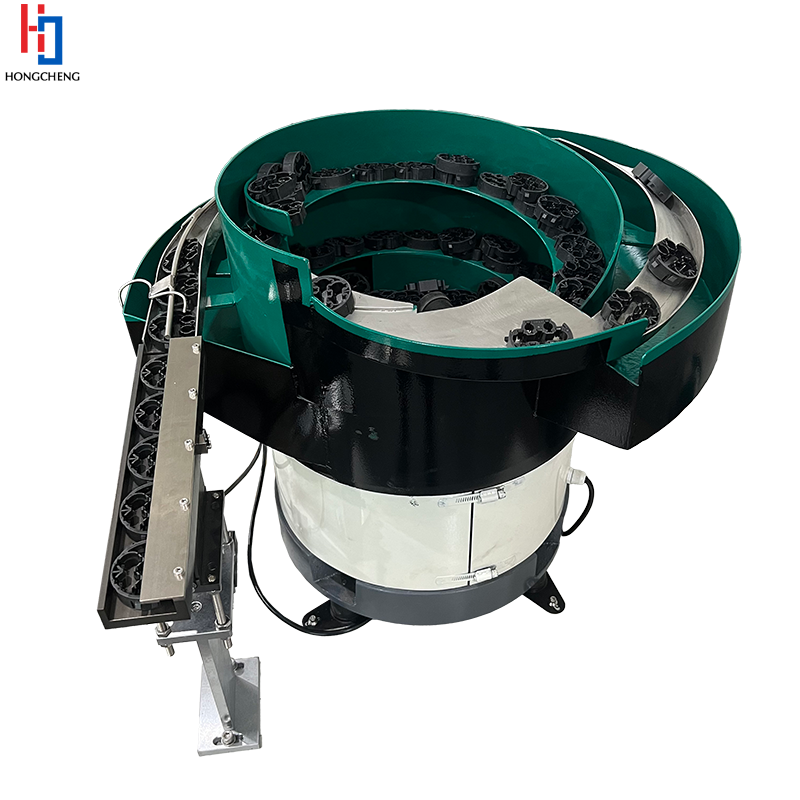

Our factory has been focusing on the production of various types of vibratory bowl feeder for many years, with rich experience and mature technology. Whether it is vibrating, centrifugal or multi-track composite, we can design it according to the shape, size and feeding method of the customer's product. We support customization, flexible structural design, smooth discharging, low noise and strong stability. Especially when facing some ultra-small or complex-shaped accessories, our R&D team can provide more suitable solutions.

Our workshop is equipped with CNC processing equipment and high-precision testing instruments. Each set of vibratory plate bowl feeder undergoes multiple rounds of testing before leaving the factory to ensure that there is no jamming, leakage or deviation during use. Our design concept is "making the production line smarter", so during the research and development process, we continue to optimize the structure to make installation and maintenance easier, and it is also convenient to connect with other automation equipment.

If you are also looking for a reliable vibratory plate bowl feeder, please contact us. No matter what material or shape you want to send, we are willing to talk to you and help you find the most suitable solution. Automation is not only to improve production efficiency, but also to optimize every production detail.