How does aluminum vibratory bowl feeder perform in a humid environment? The answer is: very reliable. Many customers worry about whether humid air, condensation, or even occasional water vapor will affect the service life of the equipment when purchasing vibratory bowl feeder, especially in coastal areas, rainy areas in the south, or some clean workshops, which have high requirements for environmental adaptability. The advantage of aluminum vibratory bowl feeder is that it not only has a stable structure, but also has a strong adaptability to humidity, is not easy to rust, and is not prone to deformation caused by hygroscopic expansion.

Aluminum itself has excellent anti-corrosion properties. After anodizing, a dense protective film will form on the surface, which greatly enhances the ability to resist oxidation and moisture erosion. Even if it is in a high humidity environment for a long time, it will not rust on the surface like some steel, nor will it crack or deform due to temperature and humidity fluctuations like plastic bowls. Moreover, aluminum has good thermal conductivity, is not easy to form local condensation, and is very convenient to clean and maintain. This makes aluminum vibratory bowl feeder suitable for use in industries with high environmental requirements such as pharmaceutical workshops, food packaging, and electronic assembly.

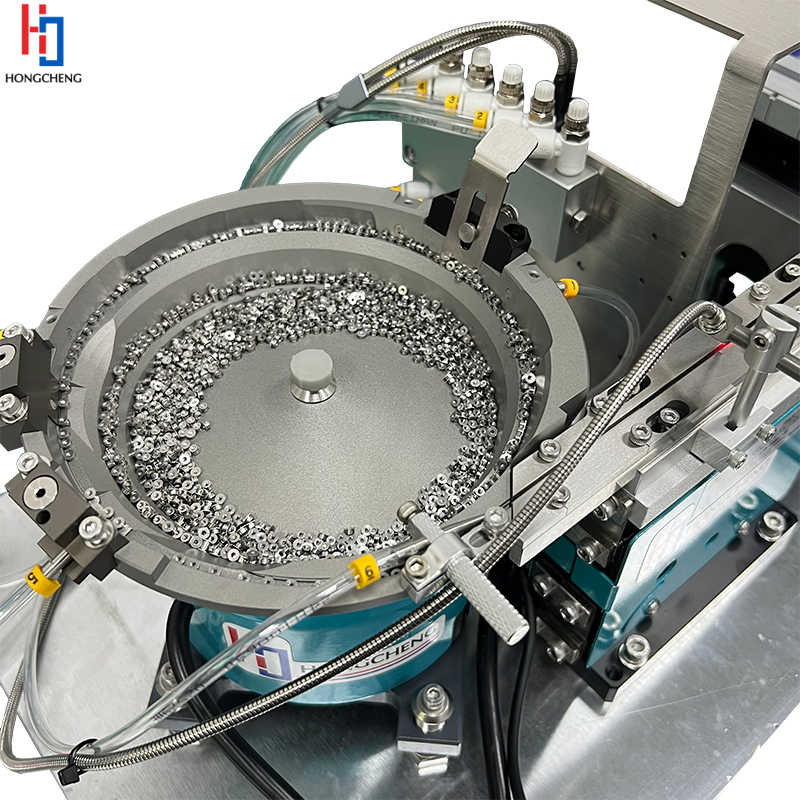

When the Hongcheng factory produced aluminum vibratory bowl feeder, it fully considered its performance under various working conditions. Each aluminum bowl is precision-processed and then anodized, which not only improves corrosion resistance, but also makes the surface smoother and less prone to dust and water accumulation. If customers have higher requirements, we can also carry out special coating treatments, such as anti-fingerprint, anti-oil, anti-static, etc., so that the equipment can still operate stably in complex environments and maintain more simply.

Our production capacity is also sufficient to support large-scale, multi-variety customization needs. The workshop is equipped with multiple five-axis CNC machining centers, which can perform high-precision engraving and polishing of aluminum materials to ensure that the guide rail structure of each bowl is fine and consistent in size. In terms of guide rail design, we can customize the exclusive channel angle and rhythm according to the sample parts provided by the customer to ensure smooth feeding without jamming. Even if the material size is irregular or the surface is easily scratched, we can also provide corresponding buffer structures or cushion accessories to truly "build on demand".

We have a customer who makes medical testing instruments. The workshop requires constant temperature and humidity, and the humidity is controlled at more than 60%. The stainless steel vibratory bowl feeder they used before had rust spots on the surface after a period of use, which not only affected the appearance, but also polluted the plastic parts. Later, they changed to our aluminum bowl. After a year, the bowl surface was still as bright as new, and the stability was also improved a lot. The customer was very satisfied, and later added more sets of vibratory bowl feeder when expanding production.

If you are also worried about the impact of humid environment on equipment, you might as well try our aluminum vibratory bowl feeder. It is not afraid of moisture, oil, or wear. The key is that it can still work efficiently, be durable and durable. We welcome you to send samples for testing, and you are also welcome to come to the factory to take a look and talk about your project requirements. We can make vibratory bowl feeder more suitable for you together. Humid environment is not a problem. As long as you choose the right equipment, it can also become part of productivity.